Integrally moulded plastic plug ring cap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

FOR PRODUCTION OF THE CRTESS CAP

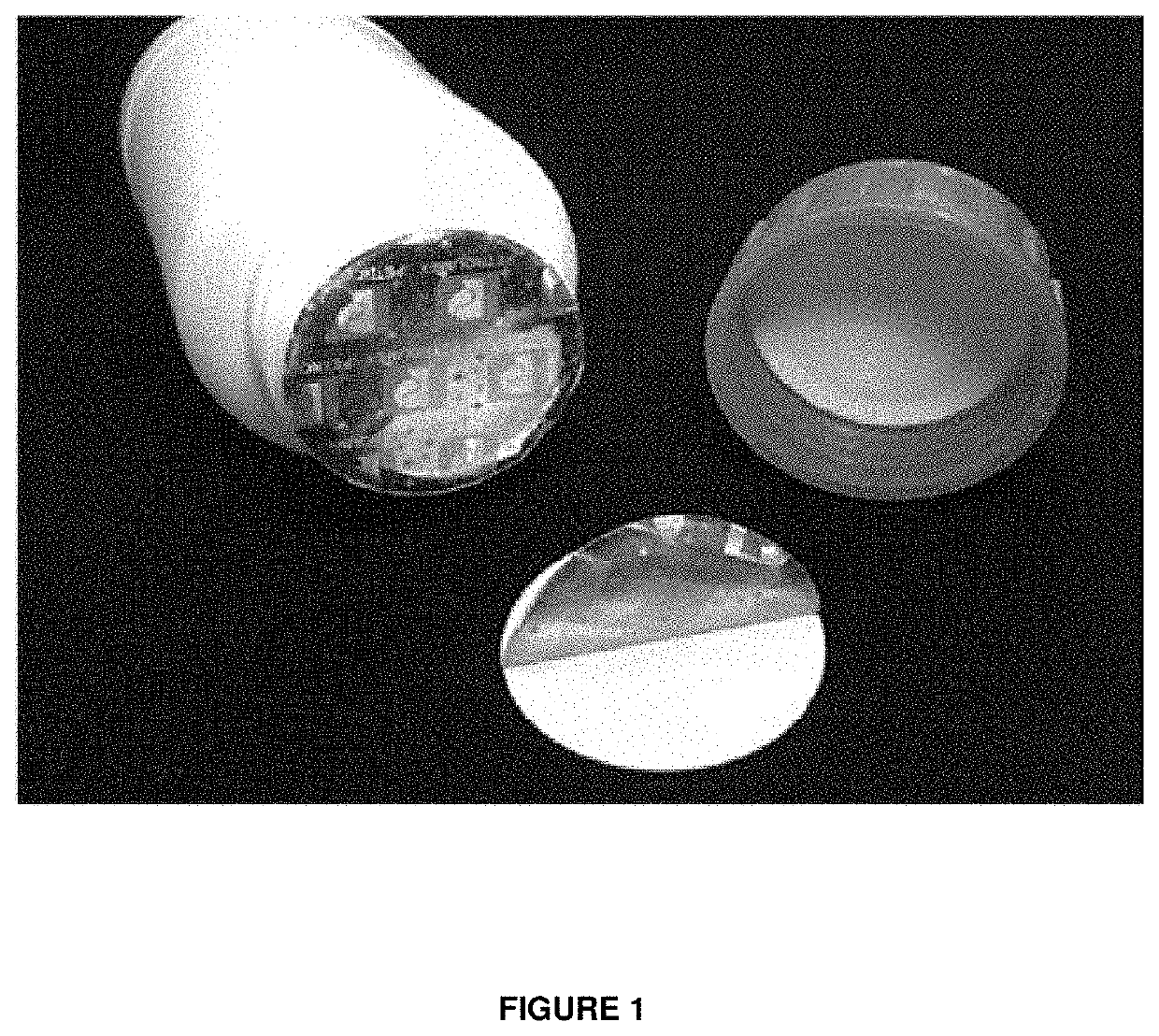

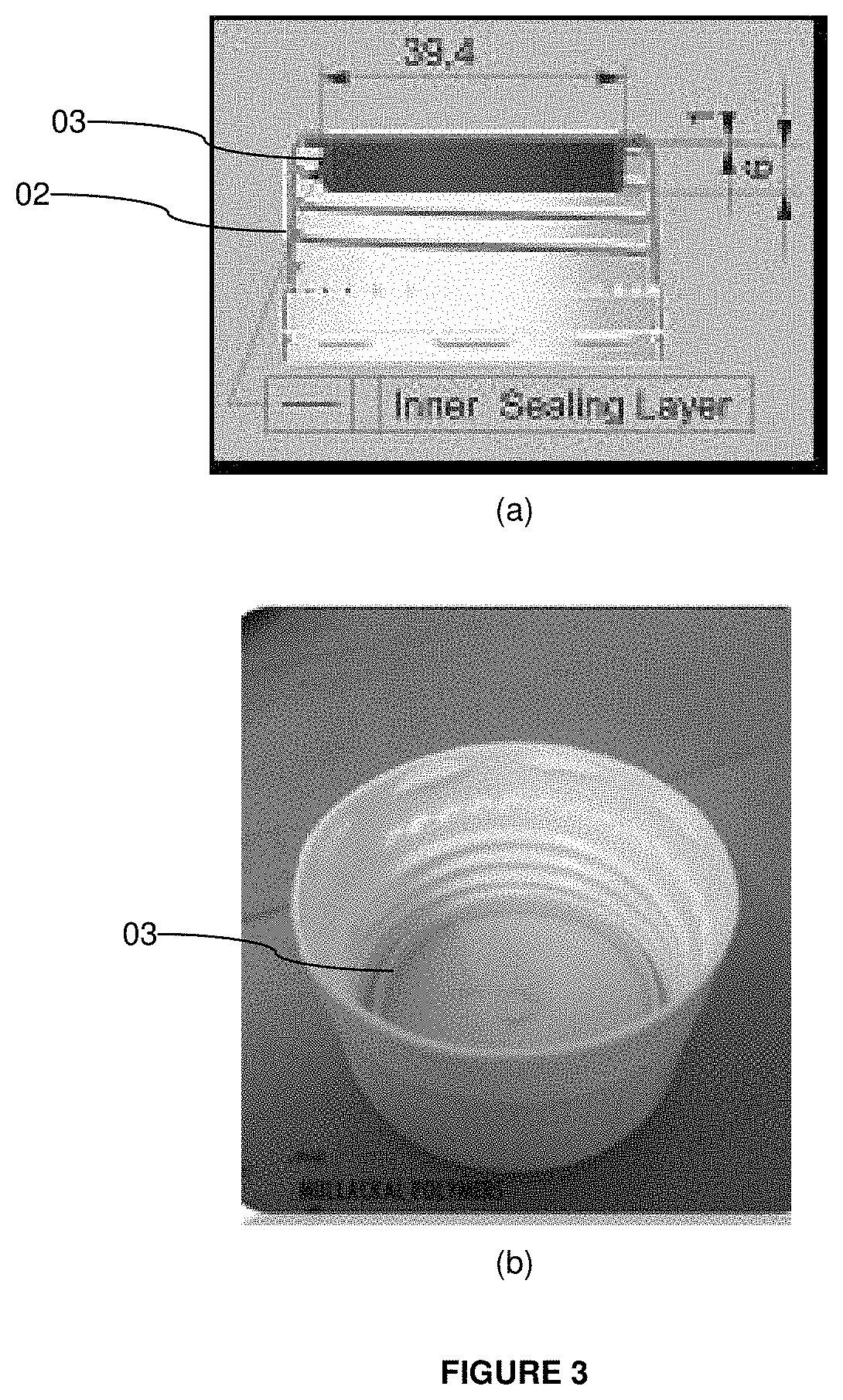

[0068]As mentioned in the foregoing disclosures, the CRTESS cap (01) proposed herein is prepared via a bi-injection moulding process wherein the inner plug ring (03) is molded first, and followed by molding of the outer shell (02).

[0069]According to one feature of the present invention evident from Example 1 above, the inner plug ring (03) is fused with the outer cap (02) during the molding process itself, hence the resulting CRTESS cap (01) has a single component / unibody construction. Hence no problems are experienced as otherwise such as wads jumping out of the caps or being displaced out of position observed in prior art solutions. FIG. 5 (a) to (d) are top view, isometric view, side view, front view, and bottom views respectively of the final product, that is the CRTESS cap (01) made according to the disclosures hereof.

[0070]In a preferred embodiment, a plastic HPDE cap is maintained during moulding at an increased temperature and sealing area is ...

example 2

F THE CRTESS CAP

[0071]a) Drop test: The CRTESS cap made using the protocol of Example 1 was received via screw fit at mouth of a liquid filled bottle. Said bottle with CRTESS cap was dropped from various heights. Here, it was observed that the bottle with CRTESS cap neither ruptures nor leakage was observed from the bottle. This concludes that the CRTESS cap successfully cleared the standard drop test applicable for articles of its nature.[0072]b) Leakage test: The CRTESS cap made using the protocol of Example 1 was received via screw fit at mouth of a liquid filled bottle. Said bottle with CRTESS cap was subjected to an air pressure of 20 kPa for 5 min. Here, it was observed that the bottle with CRTESS cap neither ruptures nor leakage was observed from the bottle or said cap. This concludes that the CRTESS cap successfully cleared the standard leakage test applicable for articles of its nature.[0073]c) Hydraulic test: The CRTESS cap made using the protocol of Example 1 was received...

example 3

VE VARIANTS OF THE CRTESS CAP

[0075]The CRTESS cap proposed herein may be produced in alternative versions depending on the specific use-case and application intended. The following versions are few non-limiting examples in this line-a)[0076]a) CRTESS Cap with a vent plug insertion option and self-sealing: As seen in the accompanying FIG. 7 (a) to (c), provision is made in the CRTESS cap itself to insert a vent plug (011). The vent plugs are third party sourced components comprising a plastic plug with a membrane inside. The membrane doesn't allow liquid to pass only air to pass. Hence any pressure difference which occurs inside the container is solved by the vent plug. In this variant of the CRTESS cap, the inventor named herein has made a provision such that the vent plug can be directly inserted into the CRTESS cap (this is unconventional as usually such vent plugs are inserted into the inner plug or comes as a part of the sealing wad)[0077]b) CRTESS Cap with complete top seal sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com