Scroll type fluid machine, method and device for forming elastic coating thereon

a fluid machine and roller technology, applied in the direction of liquid fuel engines, machines/engines, rotary piston liquid engines, etc., can solve the problems of difficult to obtain optimum coating thickness, difficult to precisely control the coating thickness of the coating layer, and difficult to obtain precise coating thickness. , to achieve the effect of reducing seizure, contact damage, and reducing the number of strokes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

(First Embodiment)

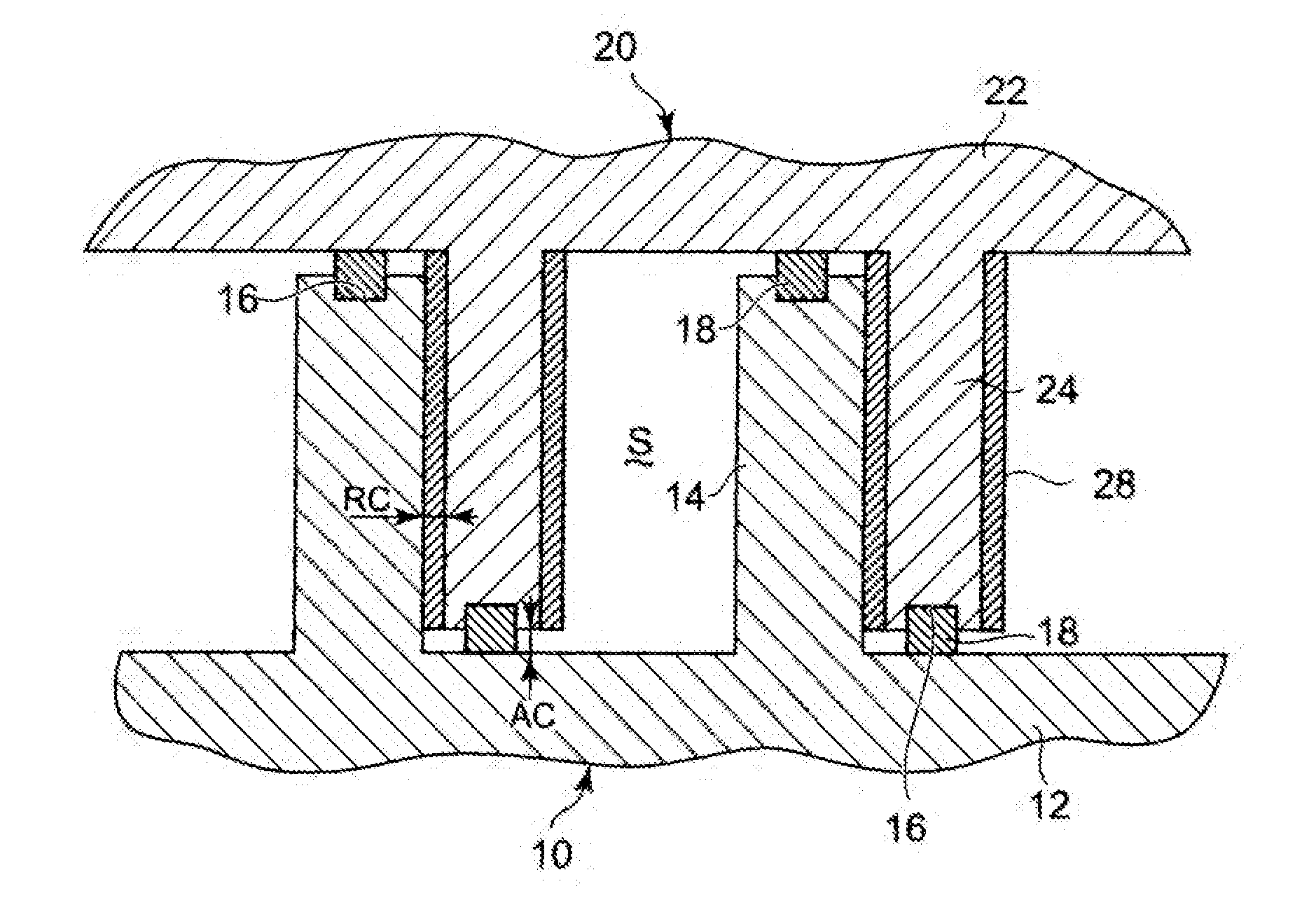

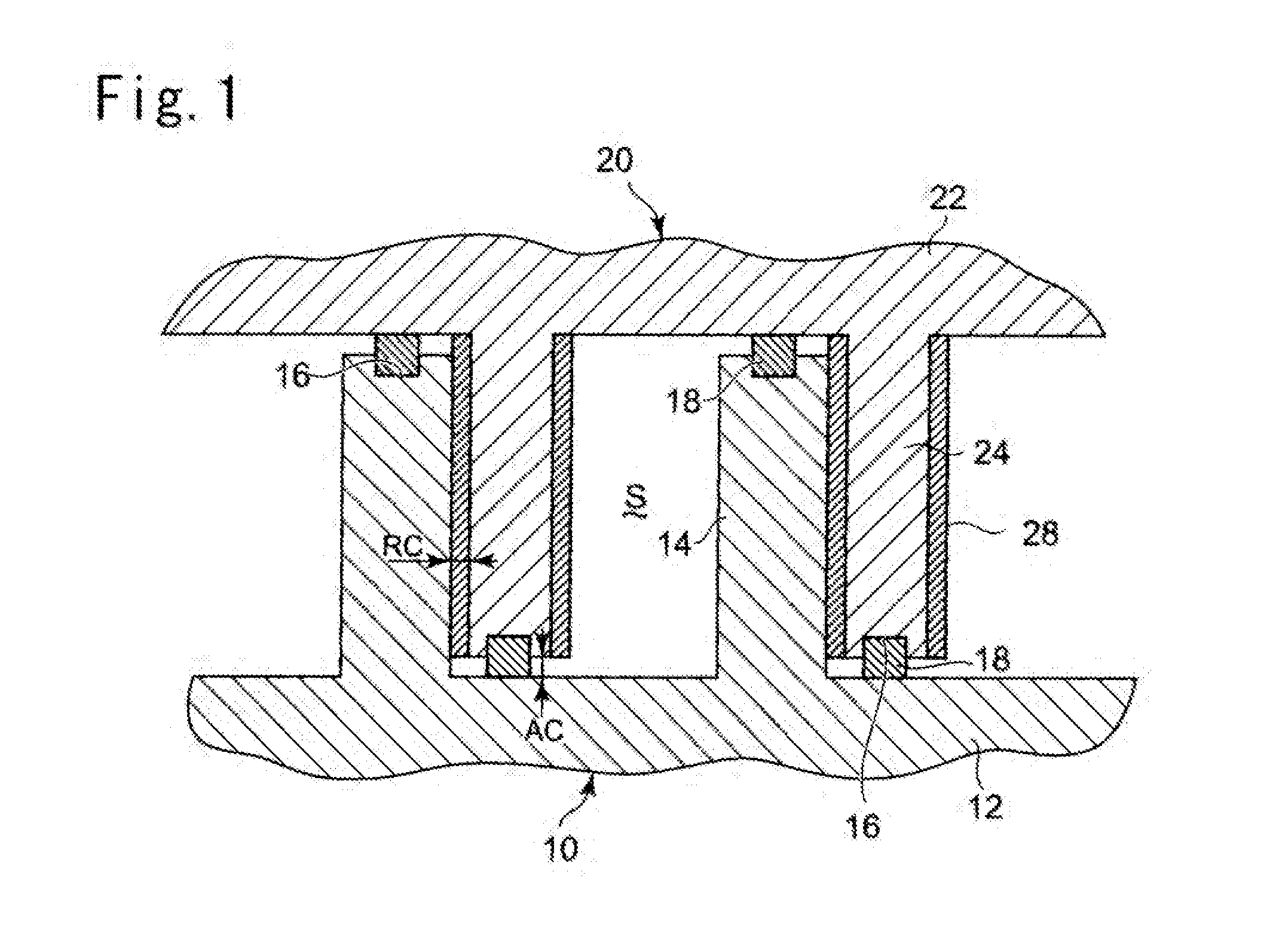

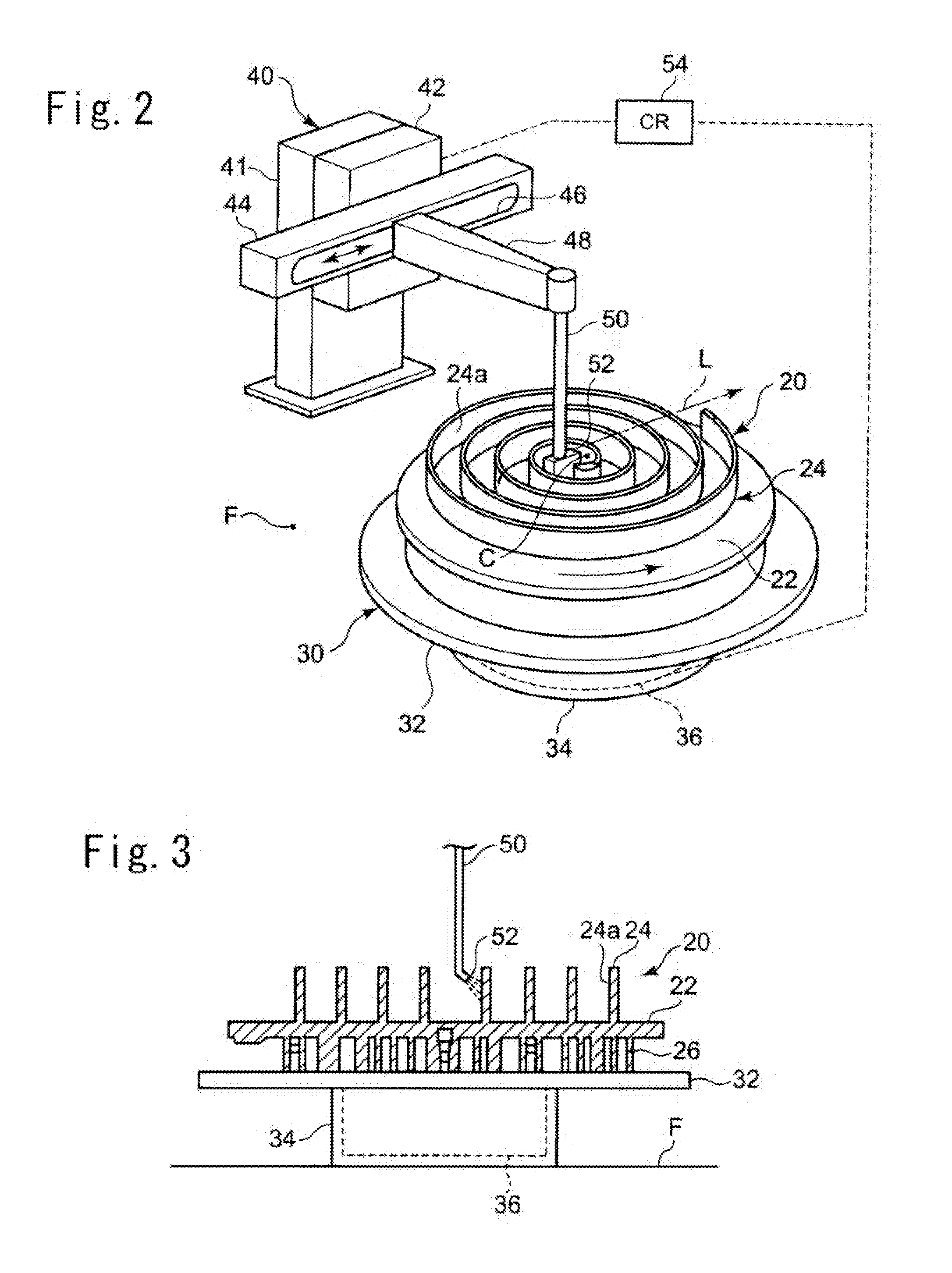

[0053]A first embodiment of a scroll type fluid machine and a method and a device for forming an elastic coating thereon according to the present invention will now be described on the basis of FIGS. 1 to 4. FIG. 1 shows a meshing portion between a fixed scroll 10 and an orbiting scroll 20 of a non-lubricated scroll type air compressor. In FIG. 1, the aluminum fixed scroll 10 is constituted by a disc-shaped end plate 12 and a spiral wrap portion 14 that stands upright from the end plate 12 in a right-angle direction. The aluminum orbiting scroll 20 is similarly constituted by a disc-shaped end plate 22 and a spiral wrap portion 24 that stands upright from the end plate 22 in a right-angle direction.

[0054]Spiral recessed grooves 16 are engraved in respective end surfaces of the wrap portions 14 and 24, and spiral tip seals 18 are fitted tightly into the recessed grooves 16. A clearance AC between the respective end plates 12, 22 and the respective wrap portions 14, ...

examples

[0068]A scroll type air compressor including the elastic coating 28 having the components and composition described above on one side face of the wrap portion 24 was operated, whereupon a damaged condition of the wrap portion 24 and a sealing condition between the wrap portion side faces were inspected. Results are shown in FIG. 4. In the inspection, the clearance RC between the wrap portion side faces of the fixed scroll 10 and the orbiting scroll 20 was changed variously, the elastic coating 28 was formed at different coating thicknesses by performing the coating formation process described above in accordance with the clearances RC, and the inspection was performed using the formed elastic coatings 28.

[0069]It is evident from FIG. 4 that when the elastic coating 28 is between 30 and 80 μm, contact between the opposing wrap portions 24 is alleviated, and therefore damage to the wrap portions can be prevented and a favorable sealing condition can be maintained between the wrap port...

second embodiment

(Second Embodiment)

[0077]Next, a second embodiment of the coating method according to the present invention will be described using FIGS. 5 and 6. A discharge port 58 of a spray nozzle 56 takes the shape of an elongated slit extending in a vertical direction. A dimension h2 of a long side of the discharge port 58 is set to be substantially identical to a height dimension h1 of the wrap portion side face 24a. Hence, when the coating solution is discharged from the discharge port 58, the coating solution can be applied to the entire region of the wrap portion side face 24a in a height direction extending from a connecting portion connected to the end plate 22 to a tip end portion in a single application. All other configurations of the coating device are identical to the first embodiment.

[0078]In the first embodiment and the second embodiment, examples in which the elastic coating is formed on the wrap portion of the orbiting scroll were described, but the elastic coating may be forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com