Wood golf club head and method for manufacturing the same

a golf club head and wood technology, applied in the field of wood golf club heads, can solve the problems of difficult to achieve a long distance impact performance, poor cushioning performance of the strike face of the conventional wood golf club head, and inability to provide a soft feel for impacting, so as to achieve the effect of increasing impact resilience and cushioning performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

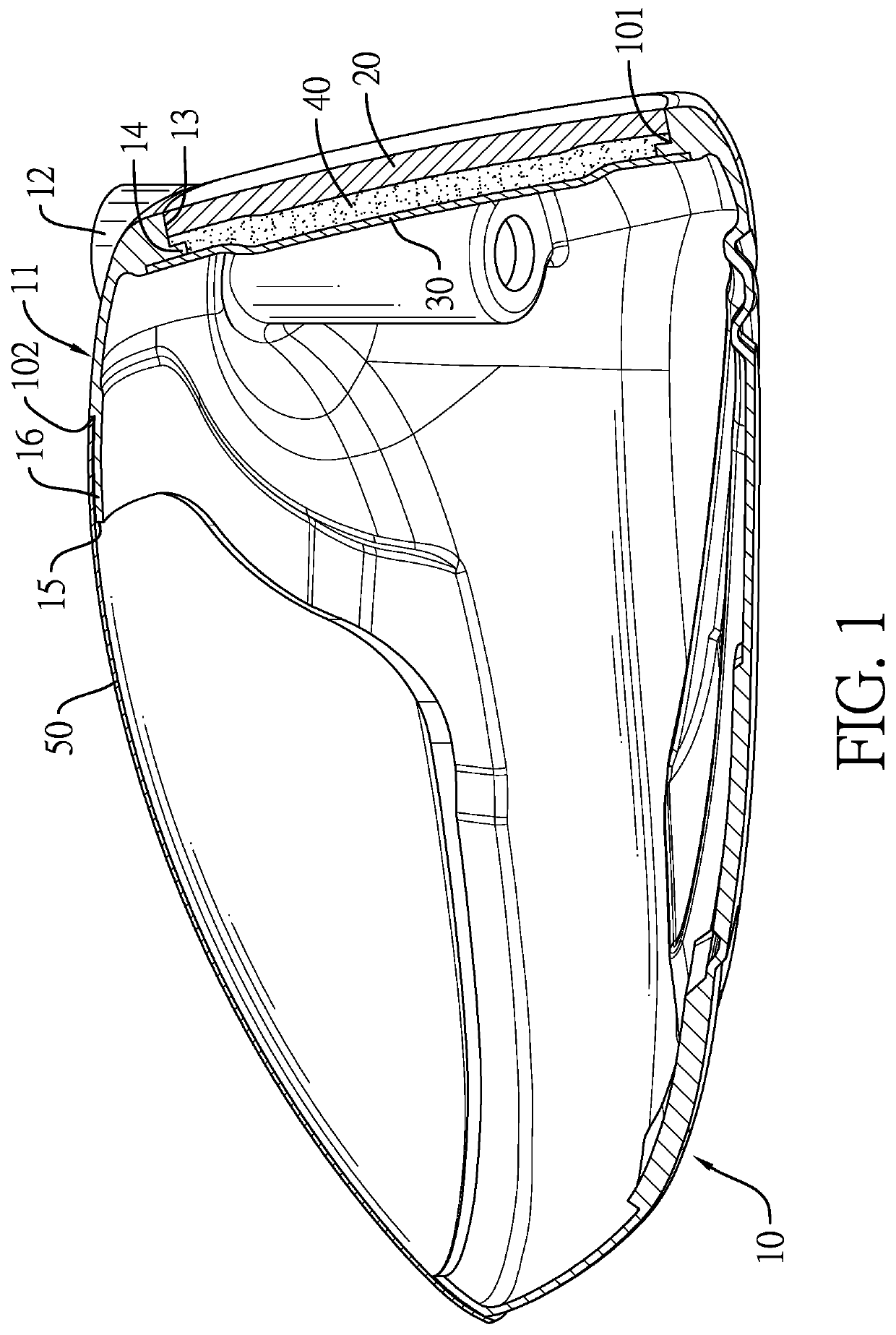

[0032]With reference to FIG. 1, a first embodiment of a wood golf club head in accordance with the present invention comprises a body 10, a strike face 20, a back plate 30, a packing chamber 60, an elastic colloid 40, and a crown 50.

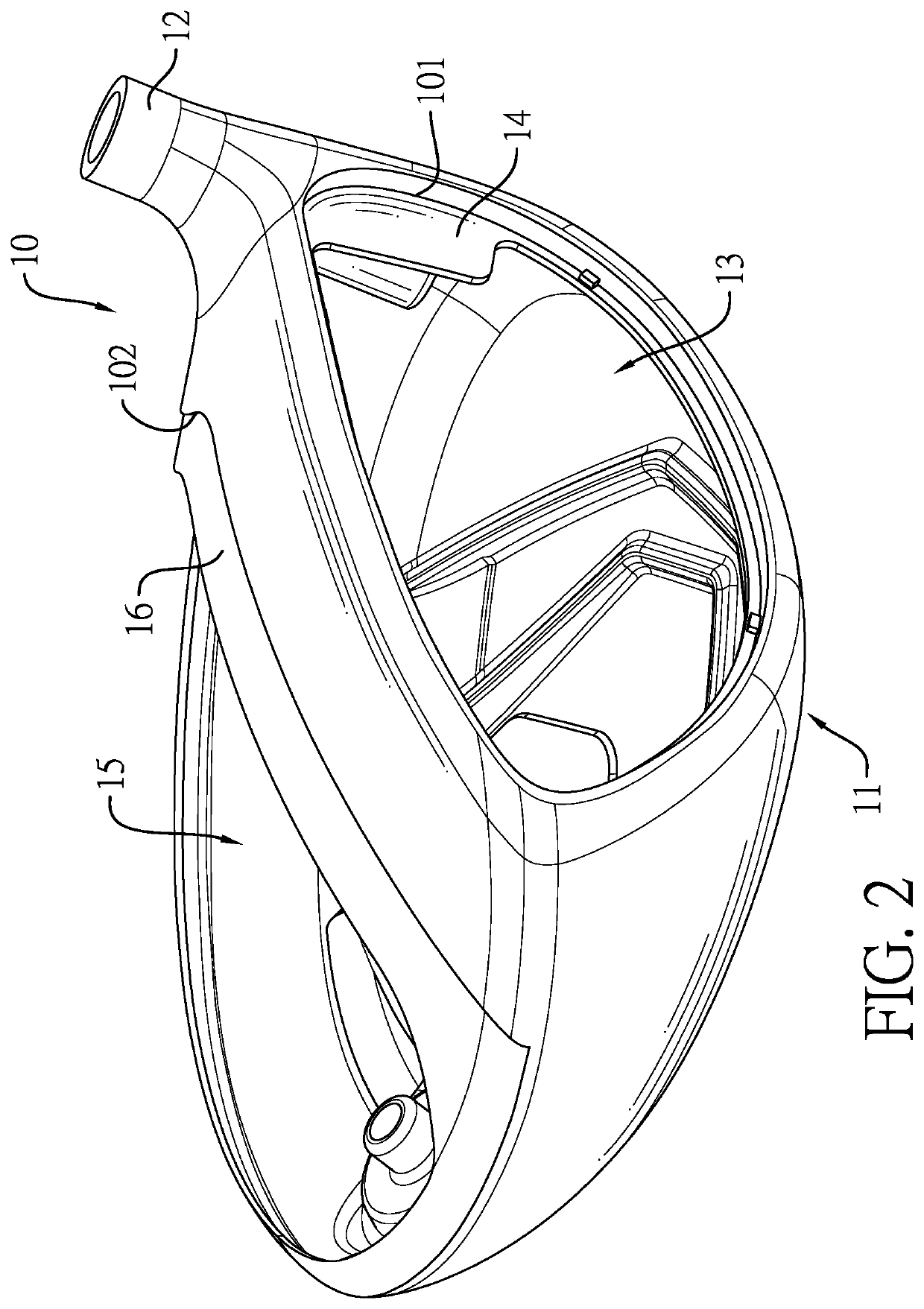

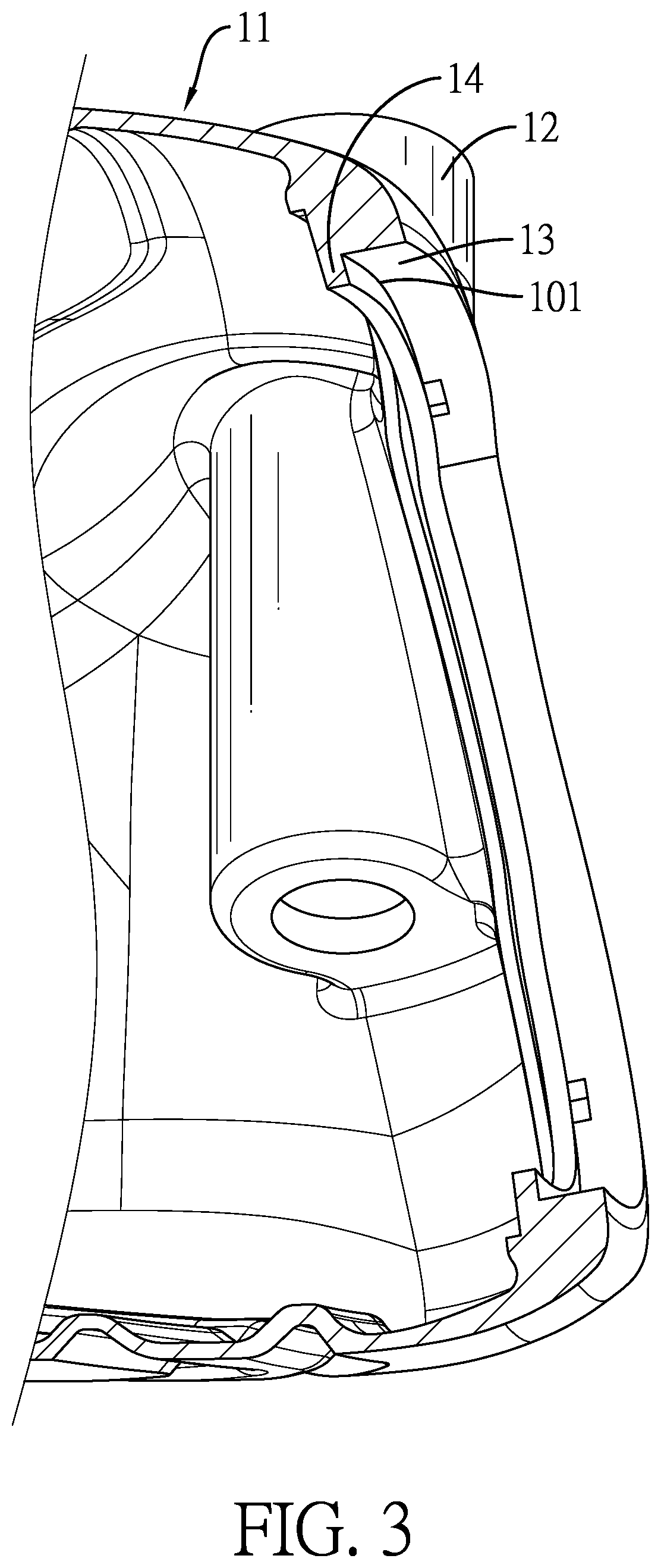

[0033]With reference to FIGS. 1 to 3, the body 10 is made of metal including titanium alloy (such as 6-4 titanium alloy or 8-1-1 titanium alloy) or stainless steel (such as SUS 630 stainless steel or SUS 431 stainless steel). The body 10 has a base portion 11 and a connecting portion 12 formed on a side of the base portion 11 for connecting a rod. The base portion 11 has a front surface, a top surface, a face opening 13, an inner edge, a fixing ring wall 14, a crown opening 15, and a connecting ring wall 16. The face opening 13 is formed through the front surface of the base portion 11. The inner edge of the base portion 11 is formed on the front surface of the base portion 11 and surrounds the face opening 13 of the base portion 11. The fixing ring wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com