Machine for packaging soft products

a soft product and machine technology, applied in the direction of conveyor wrapping, packaging, transit packaging, etc., can solve the problems of increasing the distance between the unit, and increasing the speed of the unit, so as to reduce the problem of speed reduction, reduce the productivity and the quality of the packaging of the product, and simplify the size change of the group

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

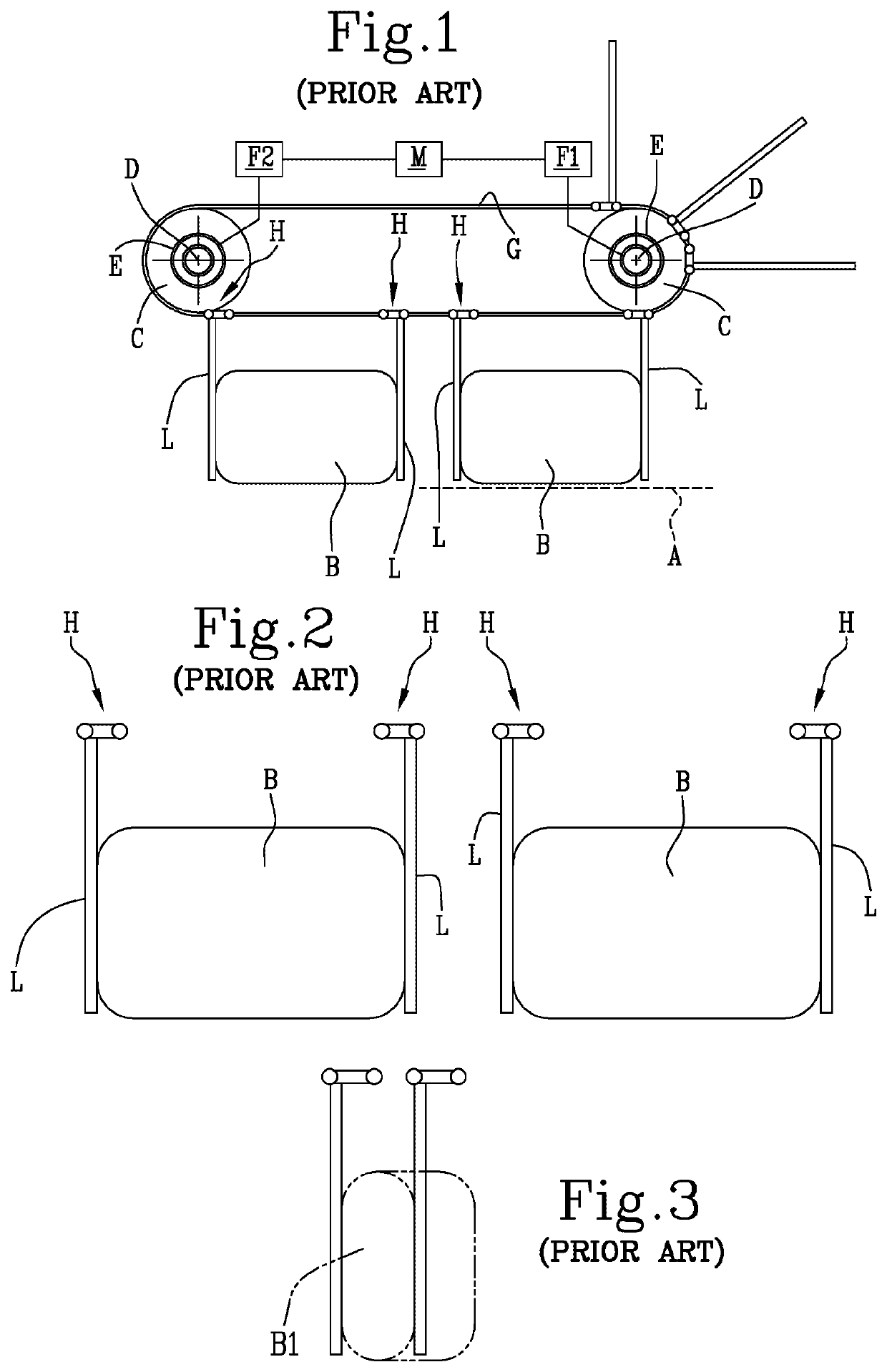

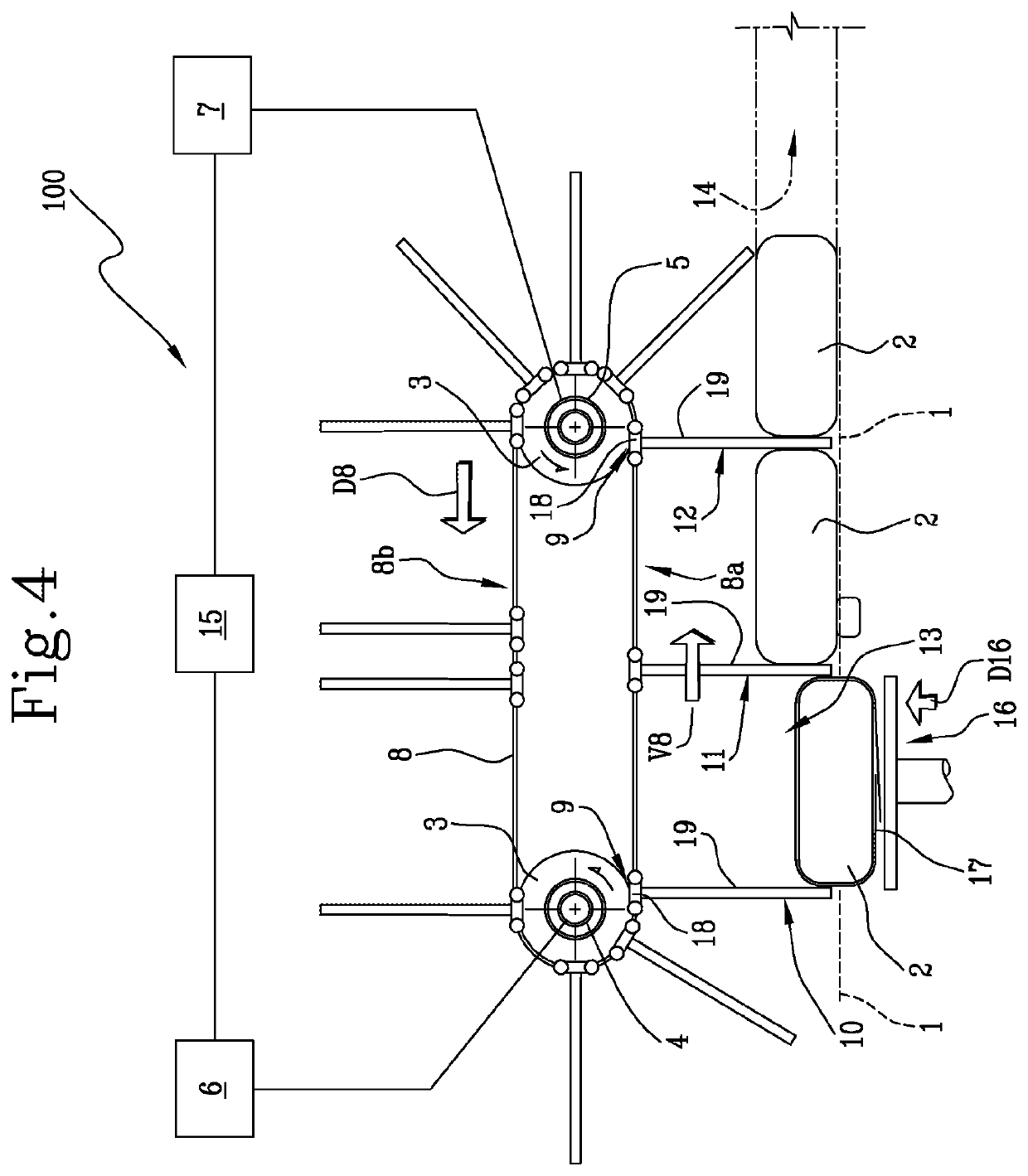

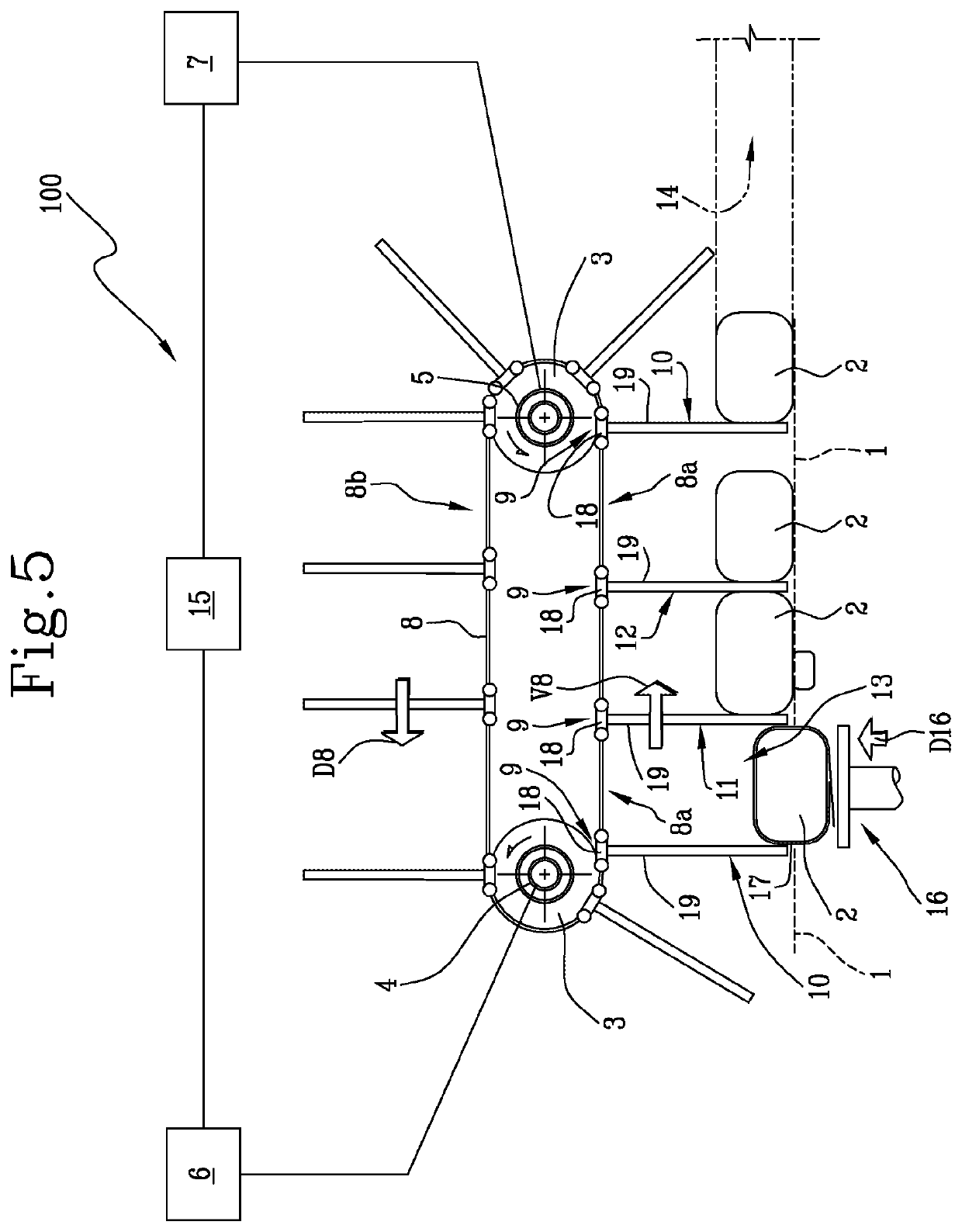

[0052]With reference to the accompanying drawings, in particular FIGS. 4 and 5, the machine according to the invention, labelled 100 in its entirety, is used for packaging soft products, such as, for example, but without restricting the scope of the invention, those for sanitary use, such as rolls of tissue paper products such as, for example, rolls of paper for sanitary and / or household use or unwoven products such as nappies.

[0053]Again with reference to FIGS. 4 and 5, the machine 100 comprises a plane 1 for feeding groups 2 of products (where groups of products may refer to a single product being wound, or a plurality of products arranged on several rows and several layers).

[0054]The feed plane 1 is usually delimited by a pair of flanks.

[0055]The machine 100 also comprises a plurality of pulleys 3 positioned at the two ends of the feed plane 1 and connected on at least two power-driven shafts 4, 5 (usually coaxial to each other and completed by a pair of driven shafts, but merely...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com