Arrangement having plural temperature-control stations for heat treating component parts, and their handling

a technology of temperature control station and heat treatment component, which is applied in the direction of muffle furnace, furnace, charge manipulation, etc., can solve the problems of reducing the effectiveness of hood-type furnaces, high degree of accuracy, and high time-consuming and labor-intensive problems of placing furnace hoods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080]Same or similar components in different figures are provided with the same reference numerals. The representations in the figures are schematic.

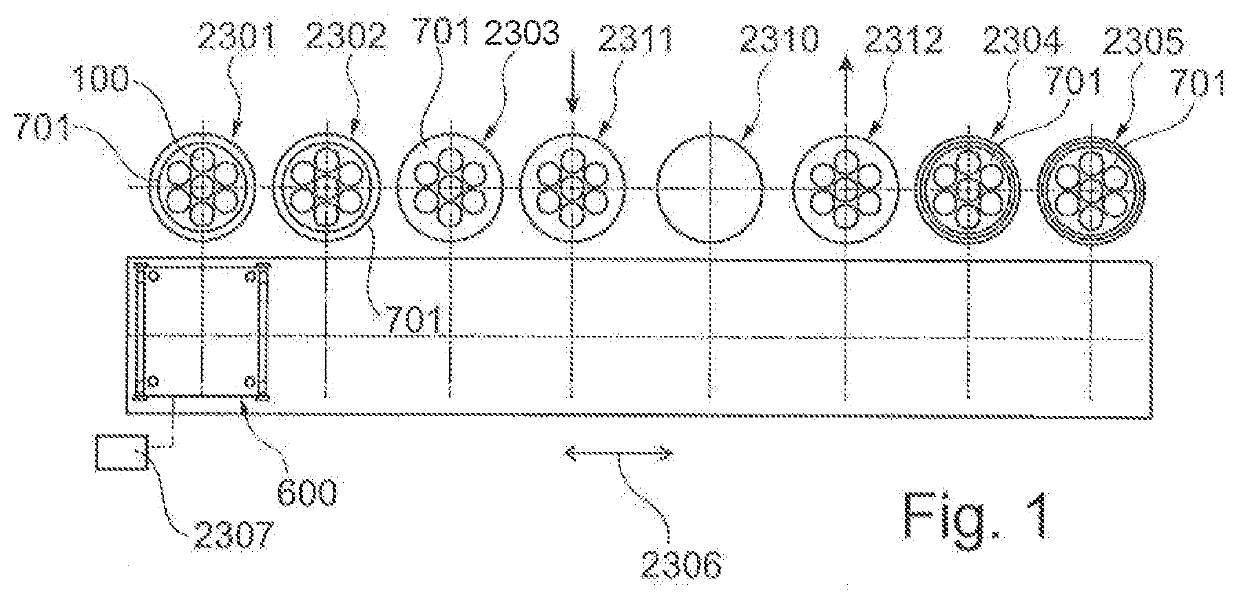

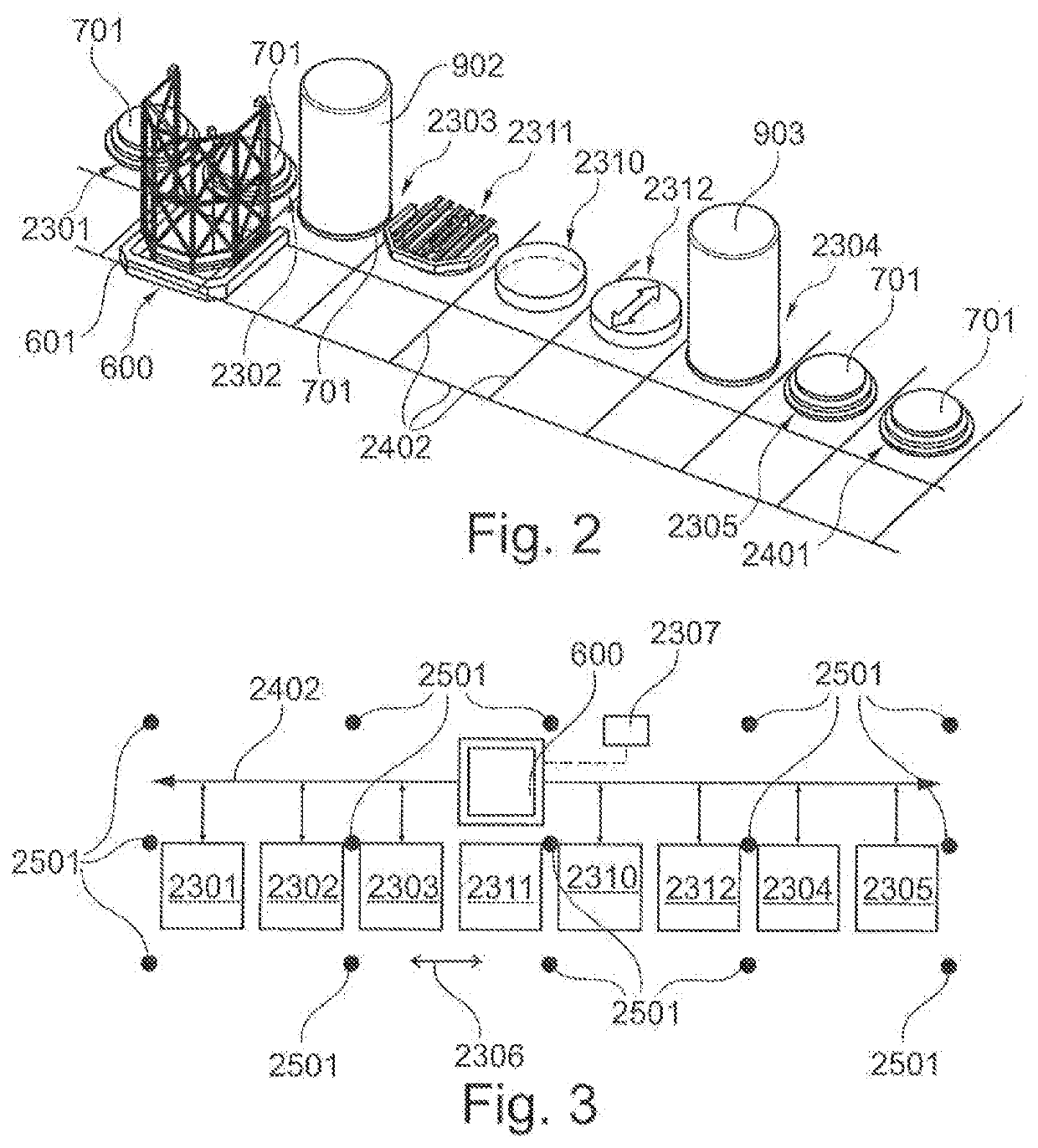

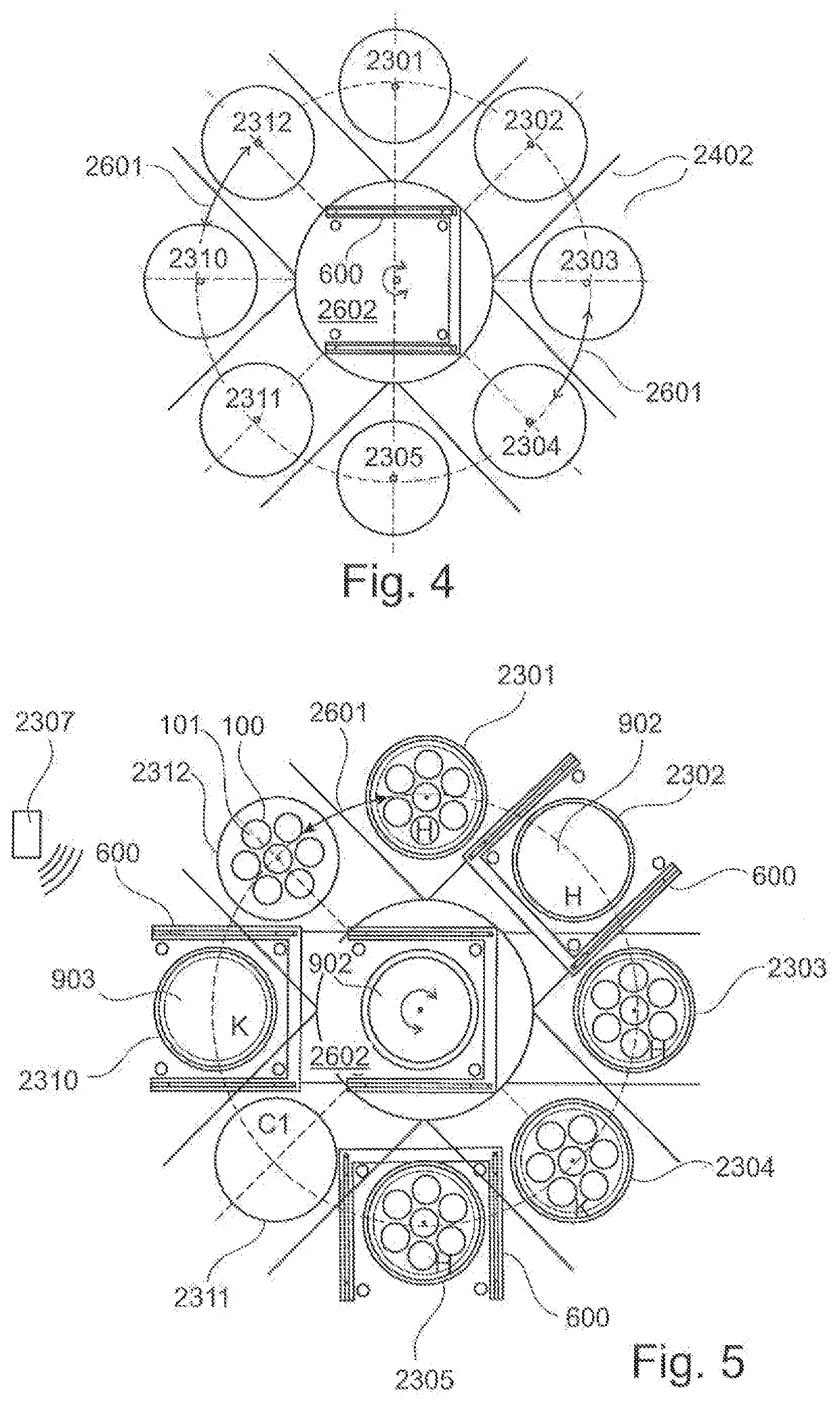

[0081]FIG. 1 to FIG. 3 show schematic representations of an arrangement having a linear apposition 2306 of temperature control stations 2301, 2302, 2303, 2304, 2305 for heat treating component parts, charging stations 2311, 2312 and a storage location 2310 according to an exemplary embodiment of the present invention. In FIG. 2, a sixth temperature control station 2401 is additionally shown.

[0082]The temperature control stations 2301, 2302, 2303, 2304, 2305 each may have a temperature control device 701, in each of which a functional device may be placeable. The functional device may for example be a charging device 100 for carrying component parts 101 to be temperature-controlled, in particular a charging device as shown in FIG. 8, a guide cylinder 801 or a furnace hood 902, 903. Furthermore, the arrangement may have two charging stat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com