Sole Structure for a Shoe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

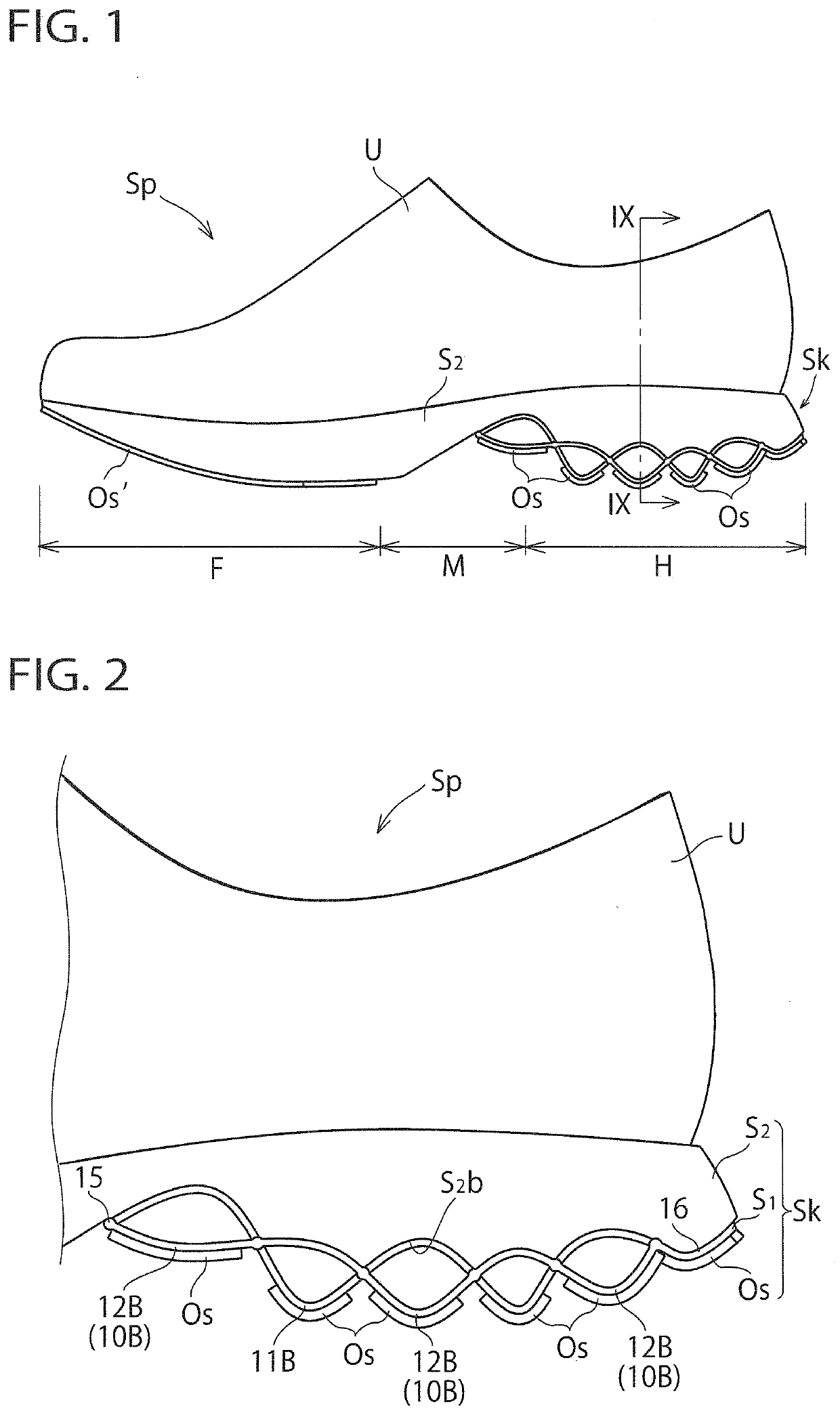

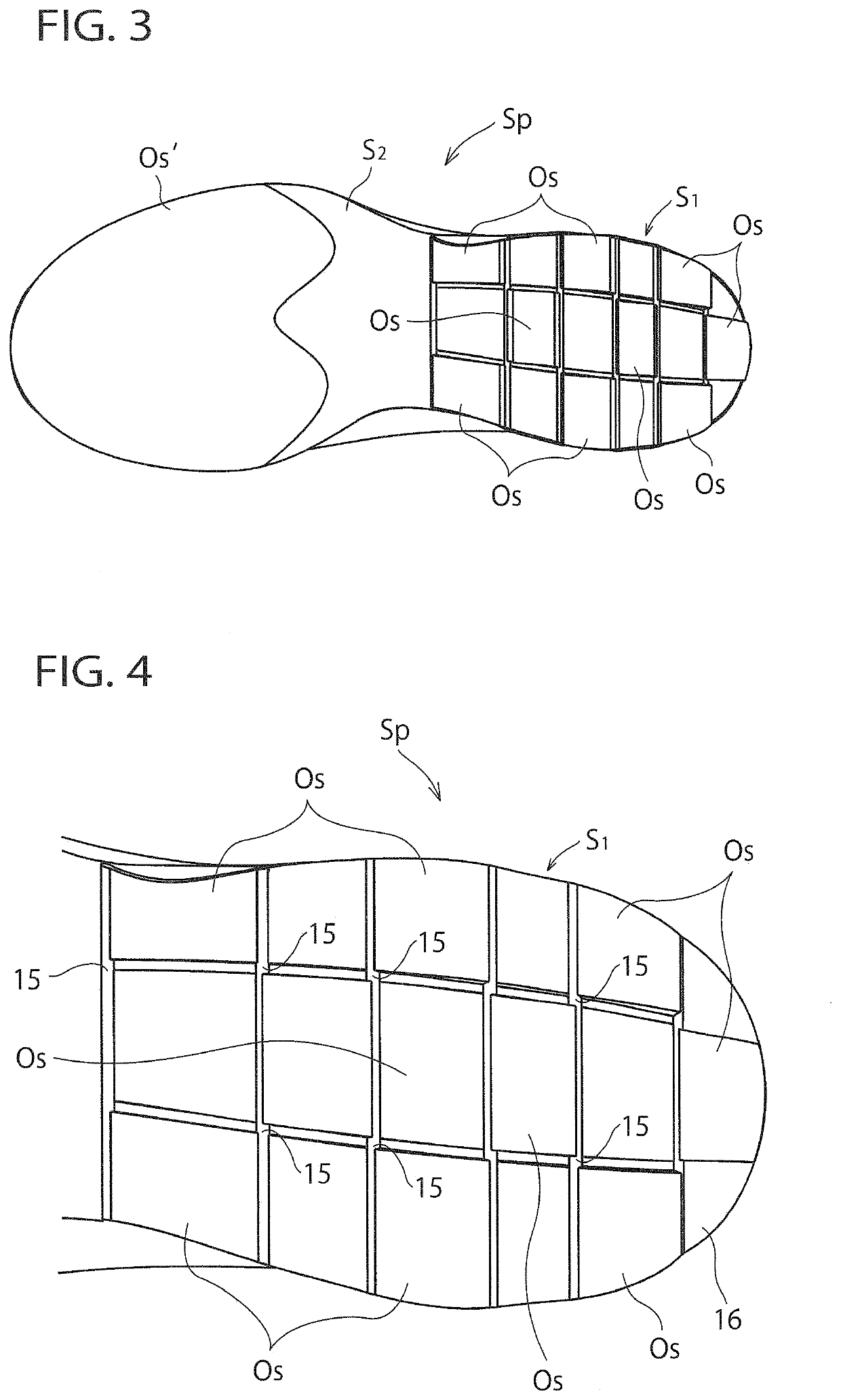

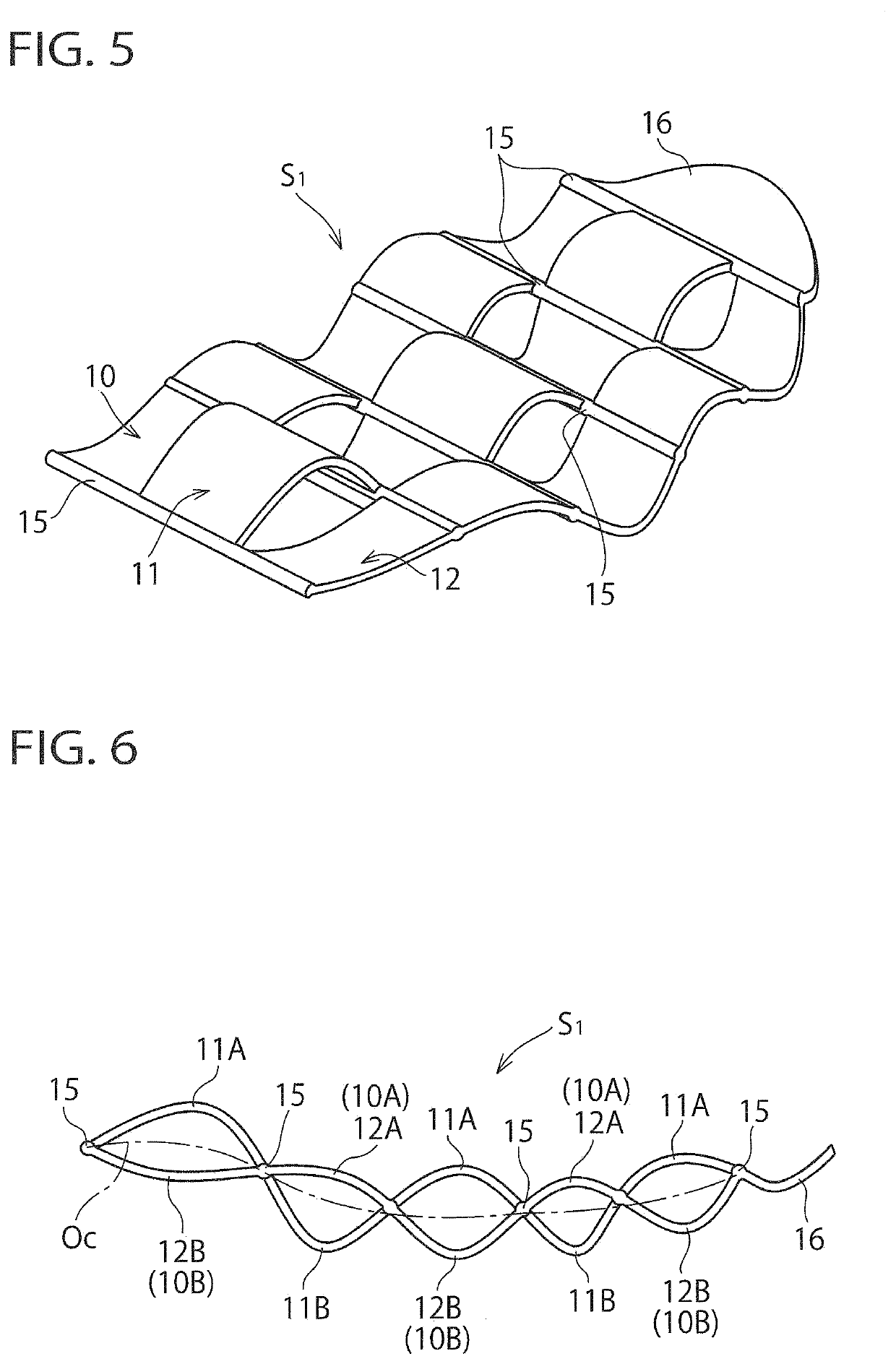

[0074]FIGS. 1 to 9 show a sole structure of a shoe according to a first embodiment of the present invention. Here, a running shoe is taken for an example, but the present invention can be also applied to a walking shoe or other sports shoe.

[0075]In the following explanation, “upward (upper side / upper)” and “downward (lower side / lower)” designate an upward direction and a downward direction, respectively, or vertical direction of the shoe, “forward (front side / front)” and “rearward (rear side / rear)” designate a forward direction and a rearward direction, respectively, or longitudinal direction (i.e. foot-length direction) of the shoe, and “a width or lateral direction” designates a crosswise direction (i.e. foot-width direction) of the shoe.

[0076]For example, in FIG. 1, a general lateral side schematic view of the shoe, “upward” and “downward” designate “upward” and “downward” in FIG. 1 respectively, or a vertical direction; “forward” and “rearward” designate “left to right direction...

second embodiment

[0095]FIGS. 10 to 12 show a sole structure of a shoe (or a running shoe) according to a second embodiment of the present invention. In these drawings, like reference characters indicate identical or functionally similar elements to those in the first embodiment.

[0096]As shown in FIGS. 10 to 12, this second embodiment differs from the first embodiment in that the midsole S2 has a pair of extensions S2h extending downwardly from the medial and lateral side edge portions. The extensions S2h, as shown in FIGS. 10 and 11, are provided principally at the midportion of the heel region H in this exemplification.

[0097]Provision of such extensions S2h facilitates a lateral positioning of the wavy structure S1 in installing the wavy structure S1 into the midsole S2. Also, after installation, a longitudinal central portion of the wavy structure S1 can be covered from the side, and after loading, a lateral movement of the wavy structure S1 can be restricted, thus improving landing stability.

third embodiment

[0098]FIGS. 13 and 14 show a sole structure of a shoe (or a running shoe) according to a third embodiment of the present invention. In these drawings, like reference characters indicate identical or functionally similar elements to those in the first and second embodiments.

[0099]In this third embodiment, an extension S2h′ extending downwardly from the midsole S2 is provided along the entire medial and lateral side edge portions of the midsole S2 at the heel region H to the midfoot region M and provided also at the heel side edge portions. That is, according to the third embodiment, the extension S2h′ circumscribes the entire heel region H and a portion of the midfoot region M along the outer circumferential edge portions of the midsole S2 at the heel region H to the midfoot region M. The midsole S2 has a concavity formed therein to accommodate the wavy structure S1.

[0100]Provision of such an extension S2h′ causes a lateral and longitudinal positioning of the wavy structure S1 to be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Structure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com