Thermoformed bakery package

a bakery package and thermoformed technology, applied in the field of thermoformed packaging, can solve the problems of reducing the strength of paperboard/cardboard, not easily formed into, and limited strength of typical paperboard and cardboard packages, so as to reduce the risk of crushing, prevent cross-contamination, and simple and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

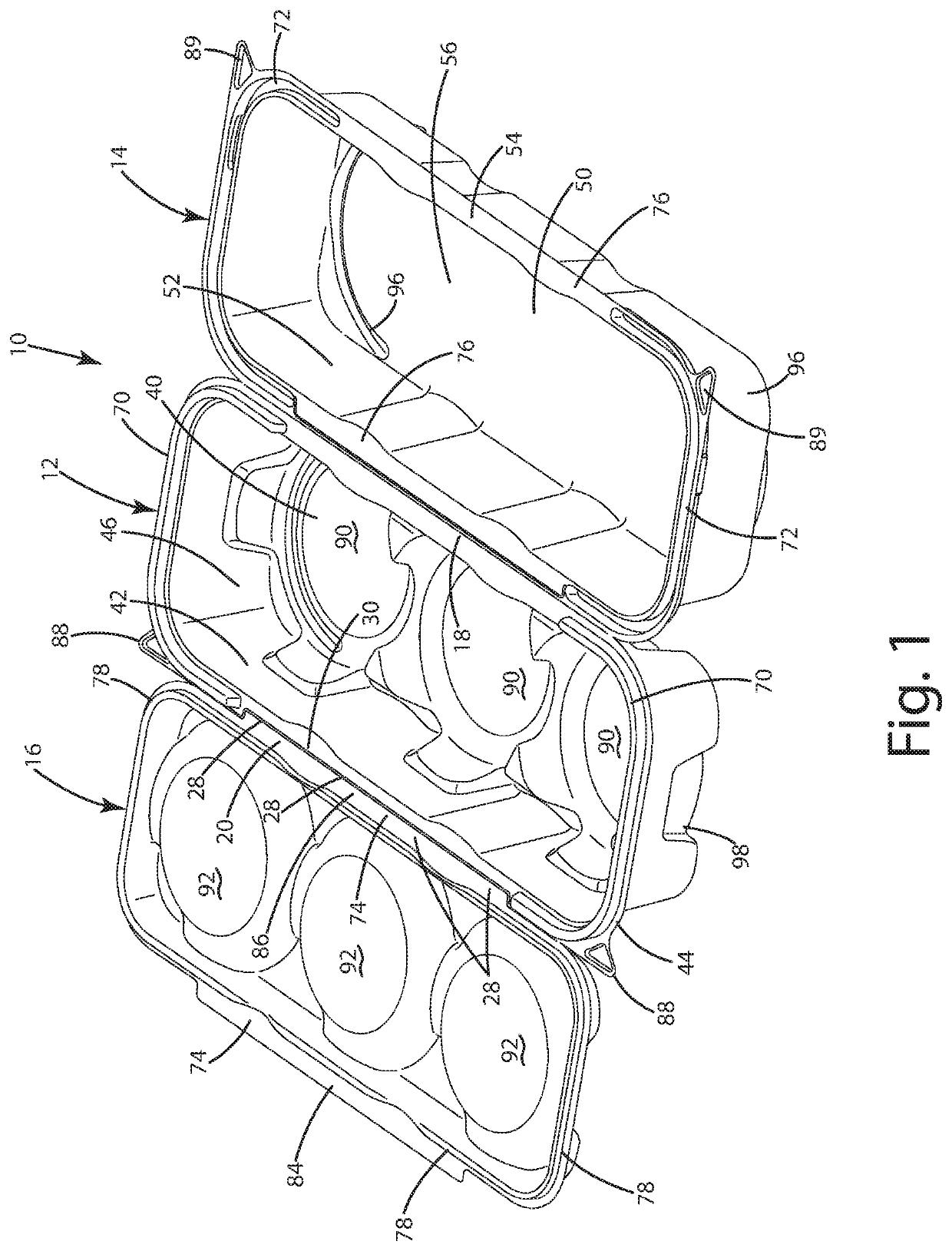

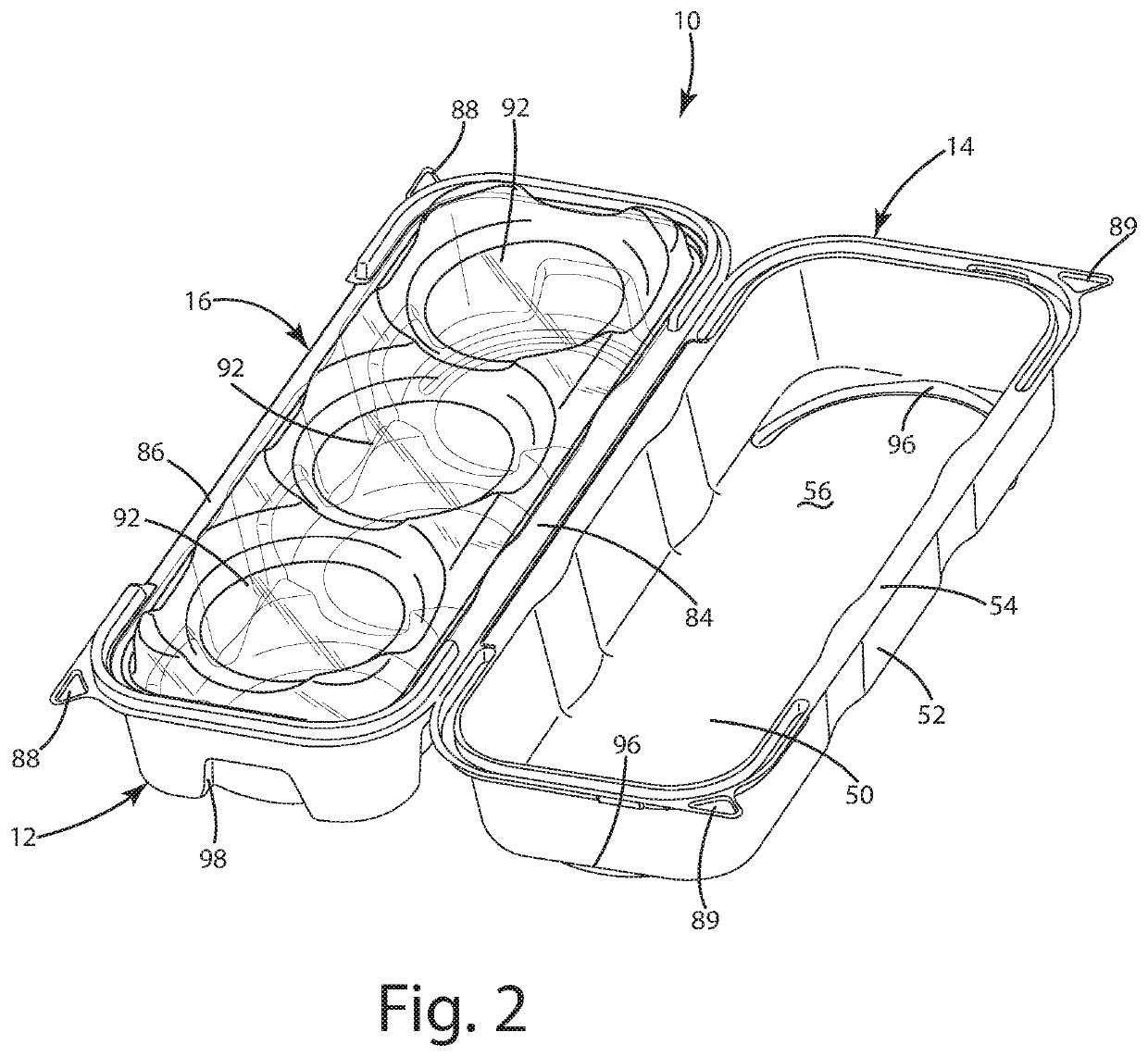

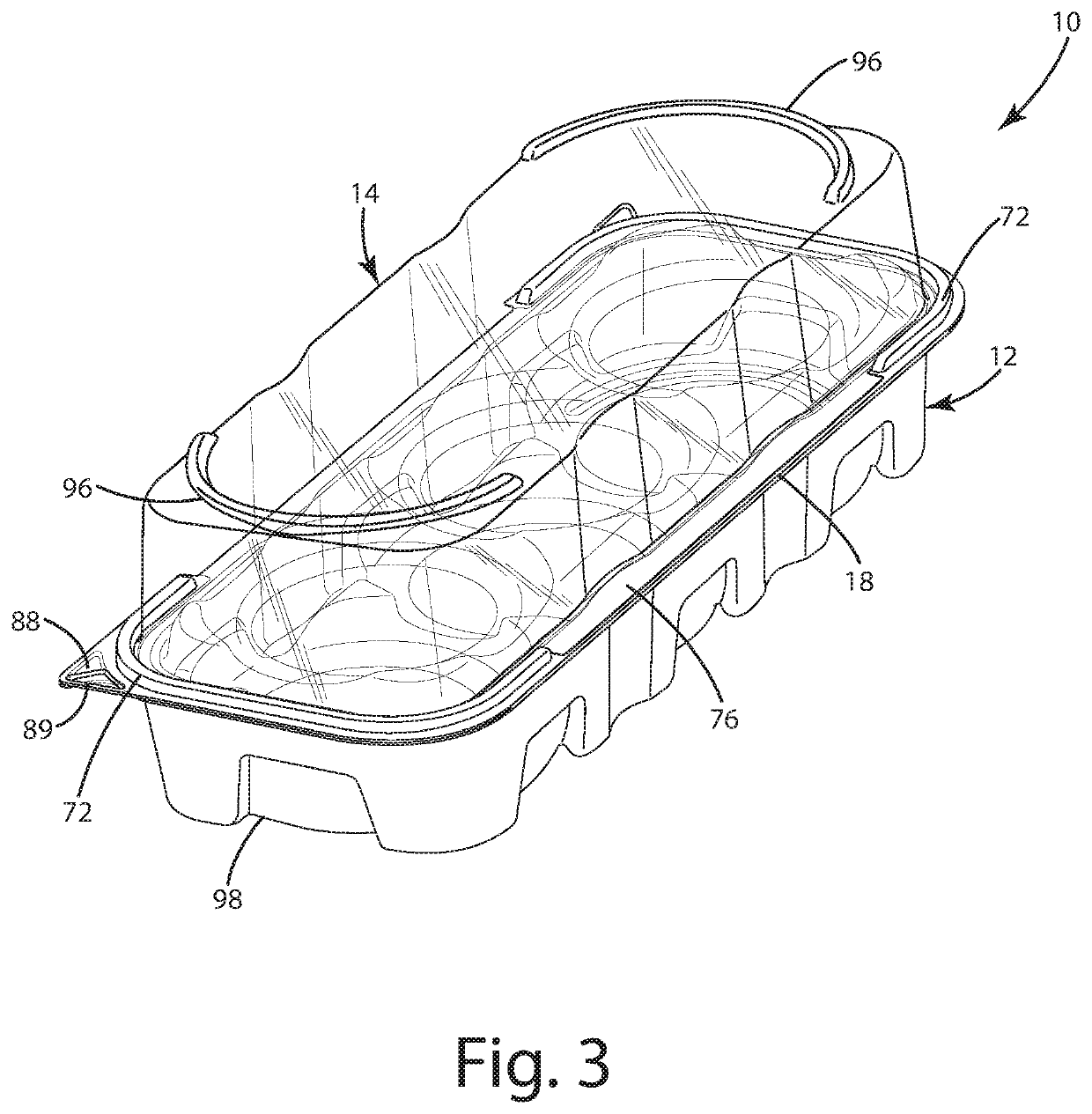

[0030]A package assembly 10 in accordance with an embodiment of the present invention is shown in FIGS. 1-4. The package 10 generally includes a bottom portion 12, a top portion 14 and an internal portion 16 that are integrally formed from a sheet of thermoformable material. The bottom portion 12 and top portion 14 are arranged in a clamshell configuration and are selectively closable to cooperatively define an internal space for receiving items to be packaged. The internal portion 16 is configured to fold into the package 10 between the top portion 14 and the bottom portion 12 to divide the internal space and form a shelf upon which items can be placed, thereby allowing two layers of items to be contained in the same package without direct stacking the packaged items. This configuration may be particularly beneficial in packaging two layers of donuts and other similar items that might be negatively affected if stacked directly one atop the other.

[0031]Directional terms, such as “ve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| perimeter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com