Method for operating an electronically commutated synchronous machine, and actuation circuit

a technology of synchronous machine and actuation circuit, which is applied in the direction of electrical apparatus, control system, ac motor control, etc., can solve the problems of inability to measure the current of the phase, inability to use a single shunt, and inability to operate an electronically commutated synchronous machine, etc., and achieve the effect of expanding the measurement region

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

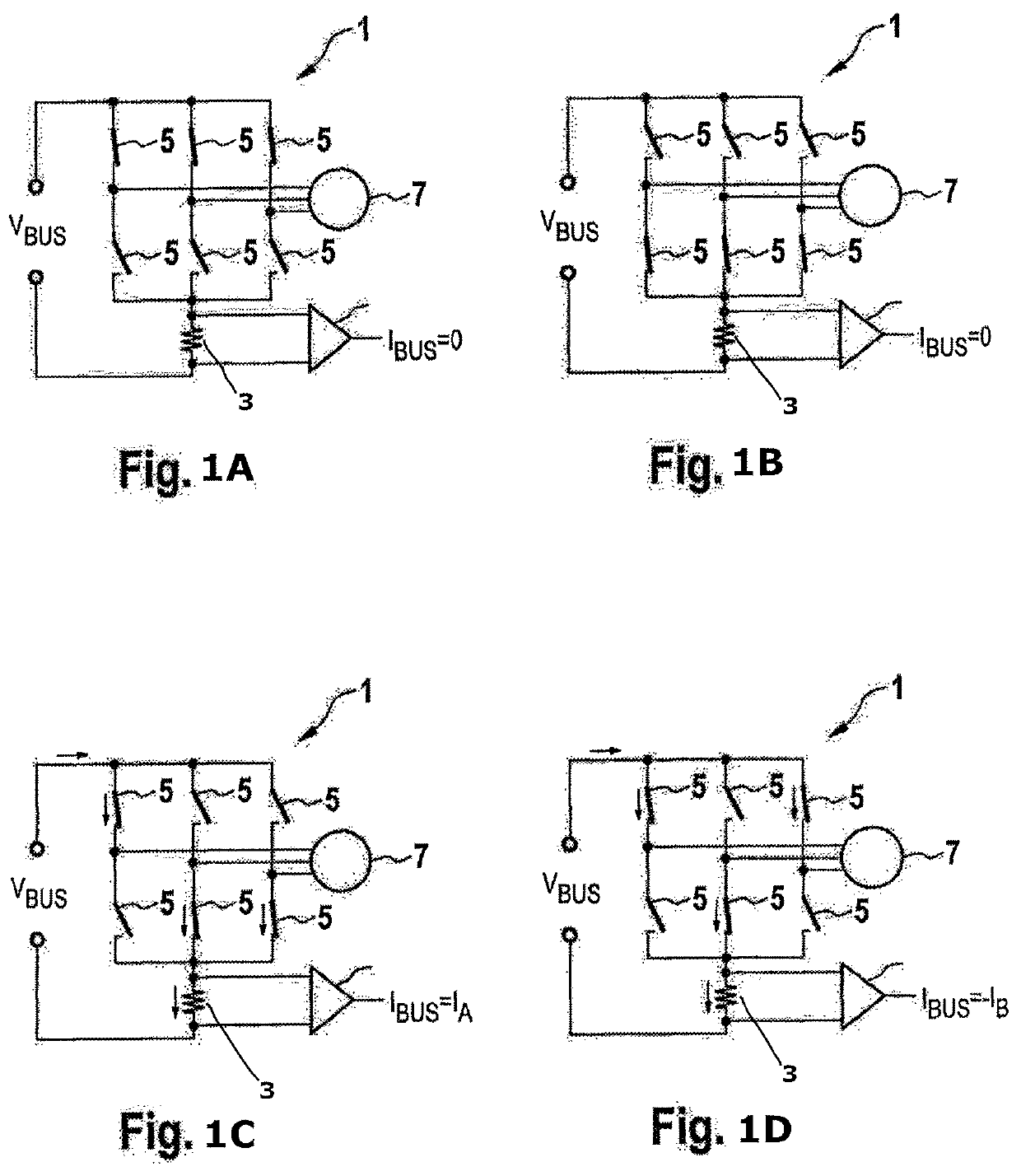

[0048]FIGS. 1A-1D show an actuation circuit 1 in various switching states with only one measurement resistor 3. Switches 5 of the actuation circuit 1 can be either open or closed. A lower switch 5 and an upper switch 5 produce a half-bridge in each case. In this case, current flows in the closed state. The current is supplied to an electronically commutated synchronous machine 7.

[0049]In FIG. 1A, all lower switches 5 are open while all upper switches 5 are closed. Therefore, all phases are short-circuited and current is not measured across the measurement resistor 3. A zero vector can be produced by this switching state. The same applies to FIG. 1B in which the upper switches 5 are open and the lower switches 5 are closed.

[0050]In contrast, FIGS. 1C and 1D do not shown the representation of zero vectors. In FIG. 1C, an upper switch 5 and two lower switches 5 are closed. Therefore, a current is measured across the measurement resistor 3. One of the six active voltage space vectors is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com