Advanced stabilizing system for deep drilling

a stabilizing system and deep drilling technology, applied in the direction of drilling rods, drilling pipes, drilling casings, etc., can solve the problems of severe drag, affecting the drilling process, so as to increase the the effect of prolonging the stabilizing system, and reducing the transversal diameter of the stabilizing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042]In the following, the invention as further described exemplarily with references to the enclosed figures. Therein, similar components are provided with same reference signs.

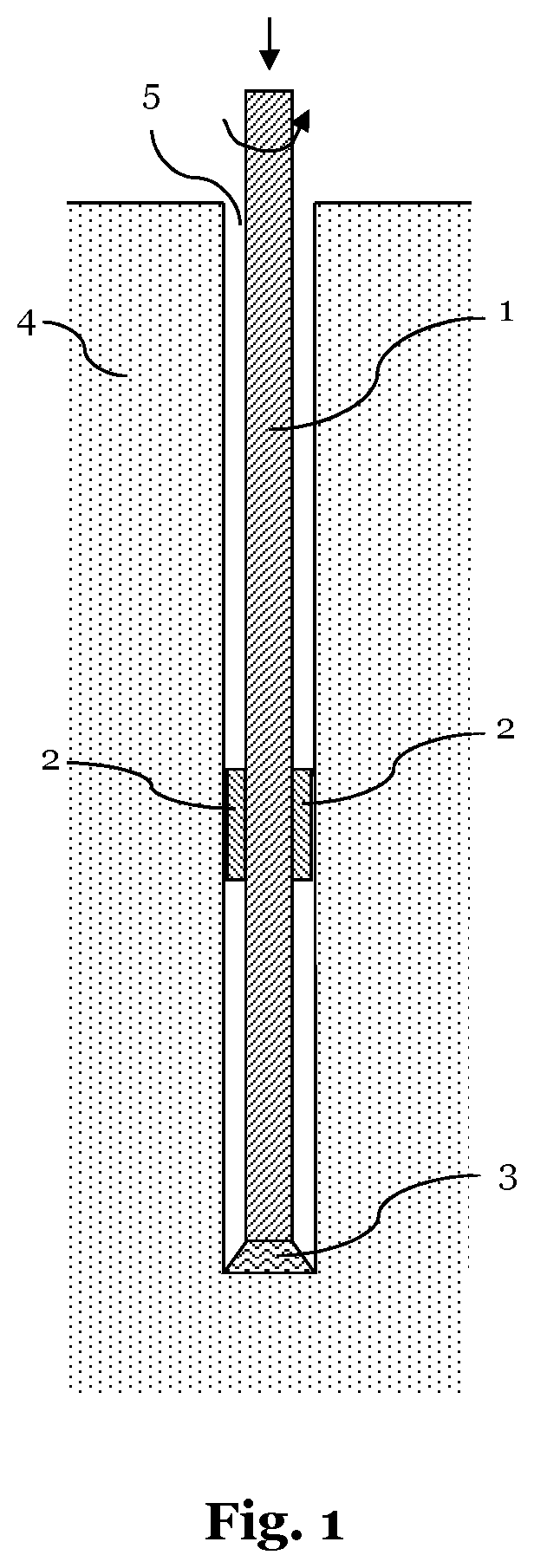

[0043]FIGS. 1-3 illustrate schematically a drilling system in different configurations.

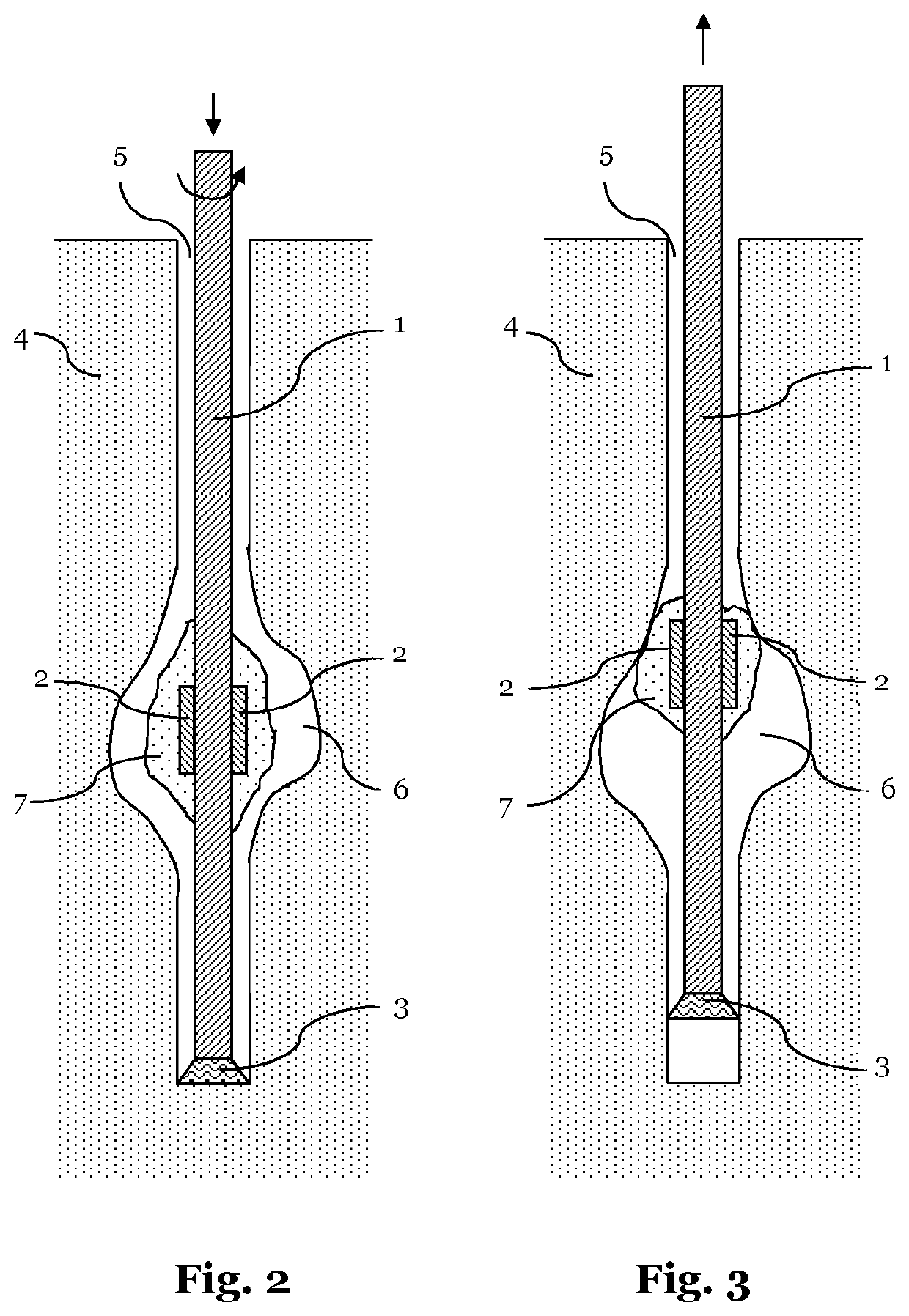

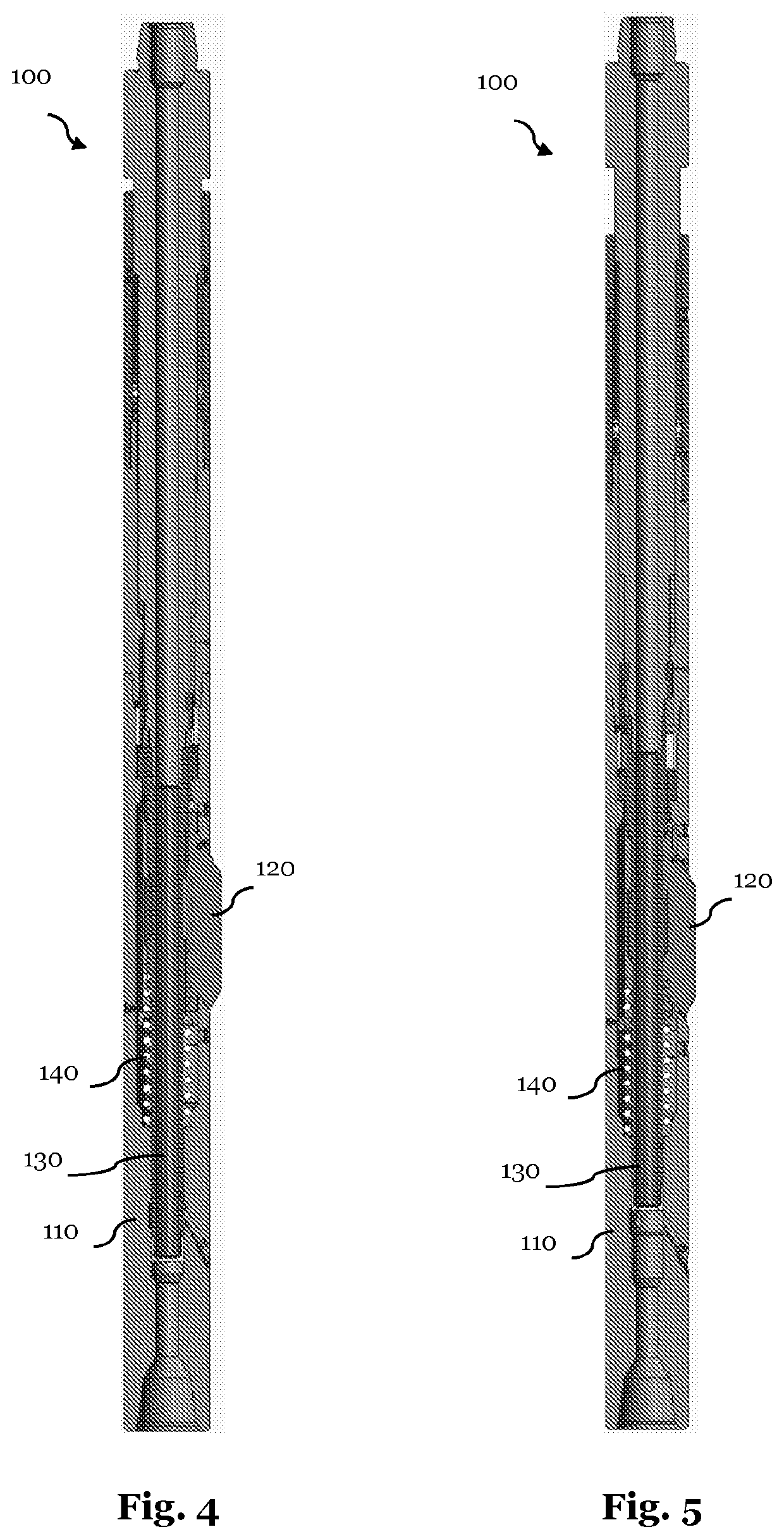

[0044]FIG. 4 illustrates a cross section of a stabilizing system according to a preferred embodiment of the present invention.

[0045]FIG. 5 illustrates the stabilizing system of the embodiment illustrated in FIG. 4 in a different configuration.

[0046]FIG. 6 illustrates particular details of the stabilizing system of FIG. 4.

[0047]FIG. 7 illustrates particular details of the stabilizing system of FIG. 5.

[0048]FIGS. 4 and 5 illustrates a stabilizing system 100 according to an embodiment of the present invention. The stabilizing system 100 is thereby adapted to be connected to drill pipes at each end thereof via respective drill pipe linkages. In the configuration illustrated in FIG. 4, the stabilizing system 100 is in a state ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com