Systems and methods for forming openings in water soluble packets

a technology of water soluble packets and openings, which is applied in the directions of packaging, transportation and packaging, successive articles, etc., can solve the problems of air trapped inside the packet with the product, the water soluble packets formed using the laser process described, and the general pliableness of the packet, so as to improve the packaging characteristics, tighten the packing, and reduce the effect of wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

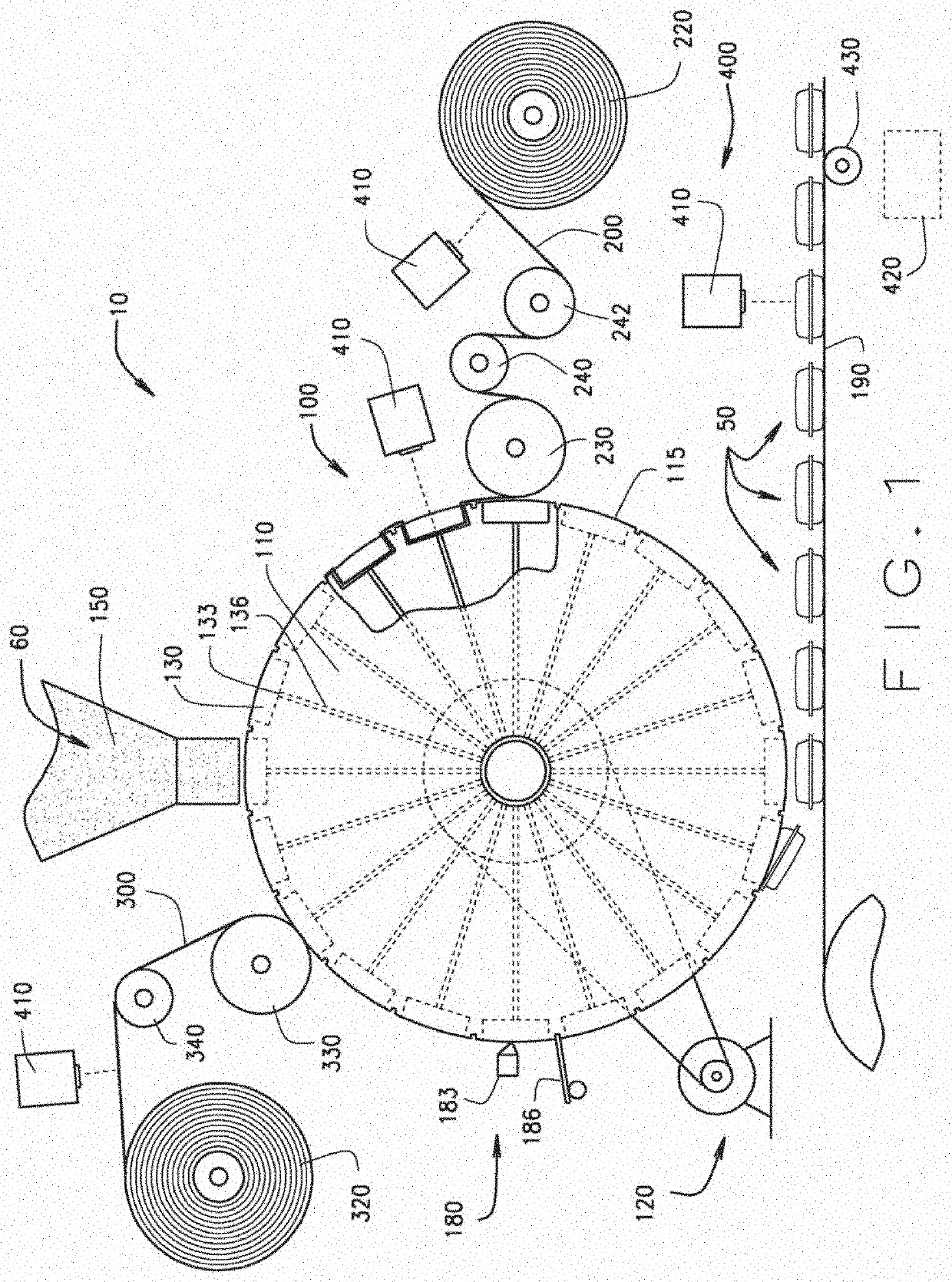

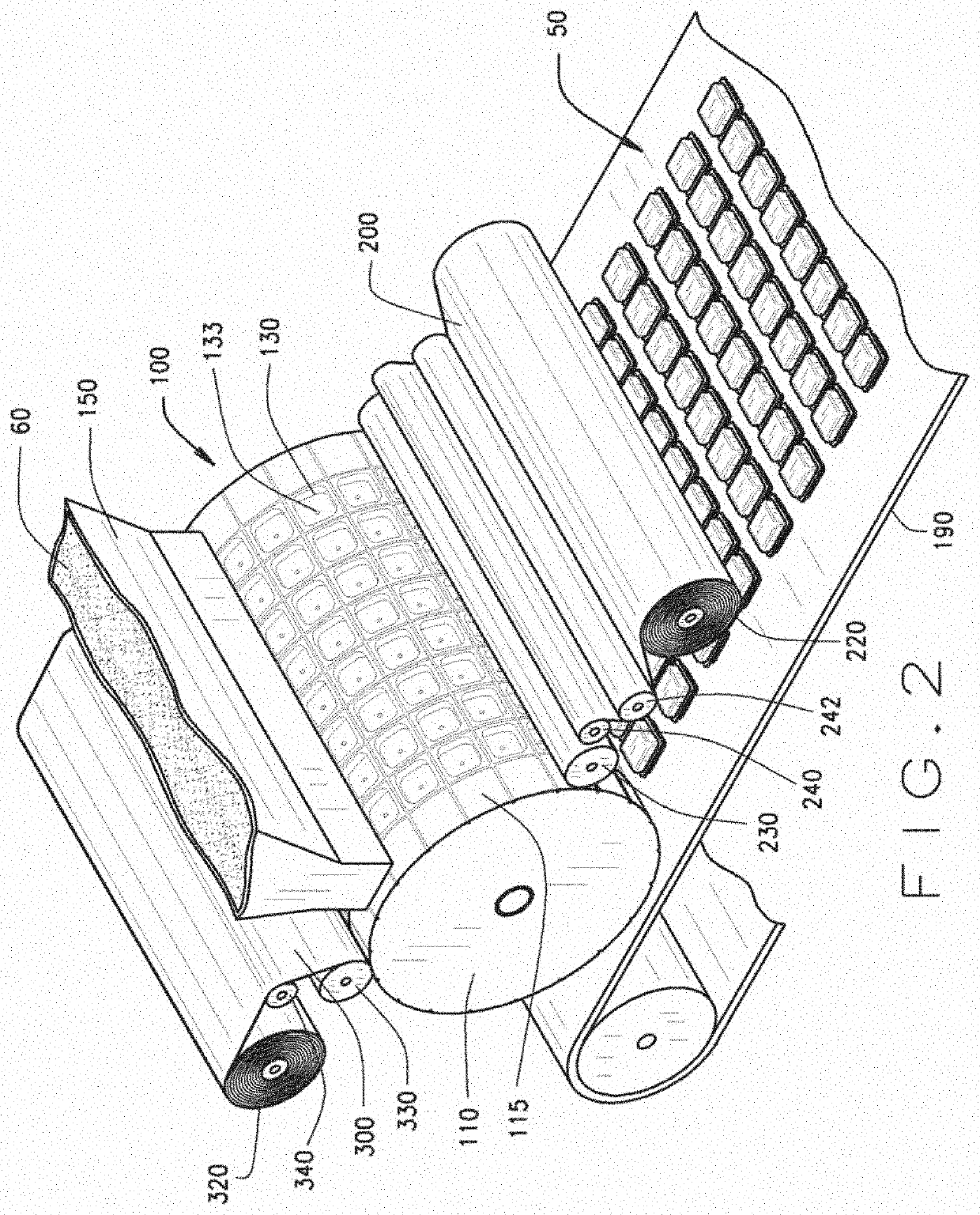

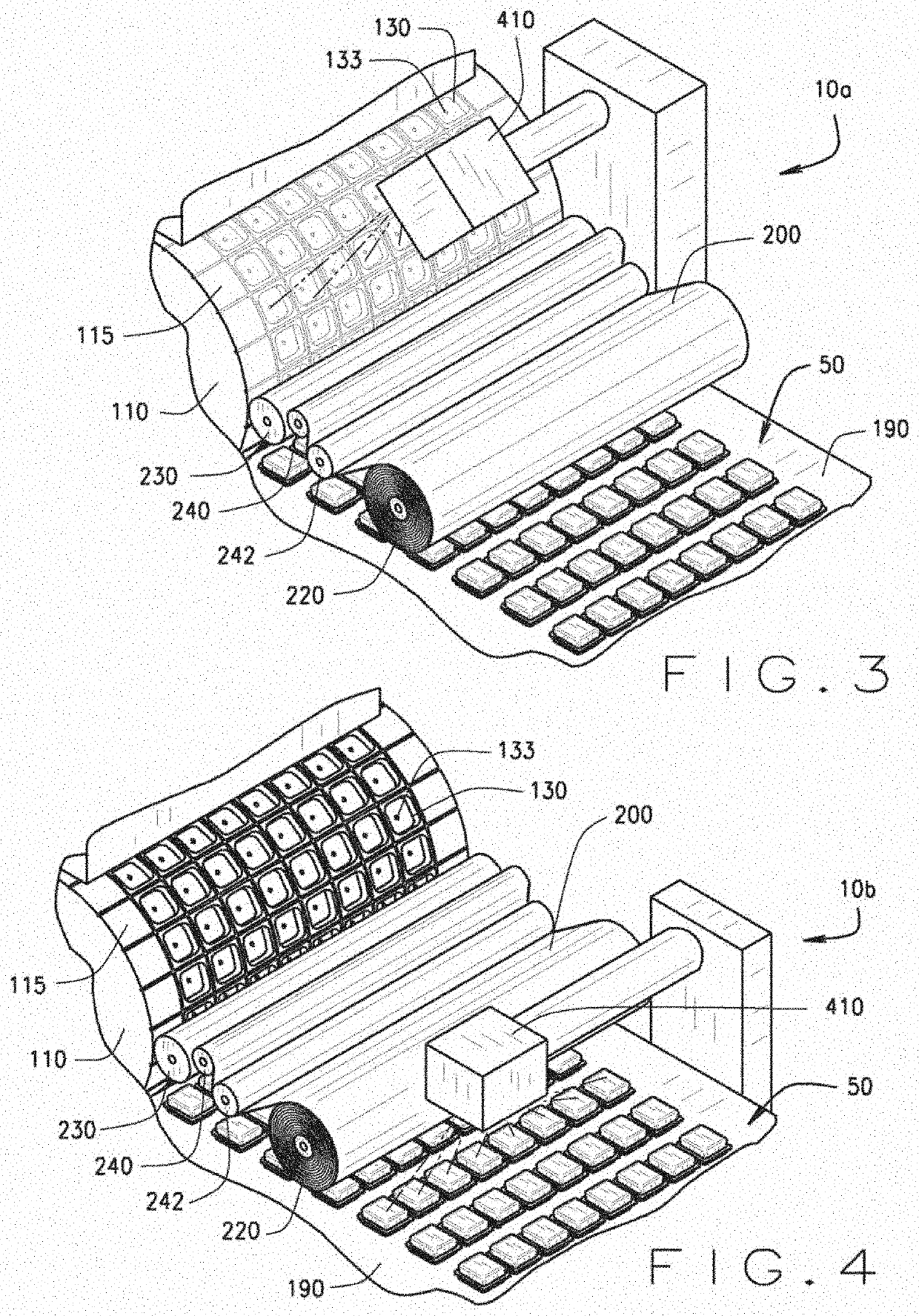

[0028]FIG. 1 is a schematic view of multiple configurations of a laser-assisted water soluble packet forming system 10, which is used to form water soluble packets 50. An example of the water soluble packet 50 is shown in FIG. 7. The system 10 forms openings 90 in the water soluble packets 50. The openings 90 are formed by a laser 410. As shown in FIG. 1, the laser 410 may be positioned at any of a number of different alternate positions about the system 10.

[0029]The water soluble packets 50 include a product 60 scaled between a base layer 70 and a lid layer 80. The base layer 70 is formed from a base film 200, while the lid layer 80 is formed from a lid film 300. The openings 90 include holes, perforations, voids, vents, etc. in either or both of the base layer 70 and the lid layer 80. As described below, the laser 410 may direct its pulses at any of the base film 200, the lid film 300, and / or the sealed water soluble packets 50. Depending upon the set-up, the laser 410 burns the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com