Artificial hair spinning nozzle and artificial hair product manufactured using same

a technology of artificial hair and spinning nozzle, which is applied in the field of artificial hair products, can solve the problems of not being suitable for hair fibers, not showing natural gloss, and limit to naturalness, so as to reduce gloss, maintain curl generation and retention, and give more hair volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]Hereinafter, an artificial hair spinning nozzle according to the present disclosure will be described with reference to the accompanying drawing.

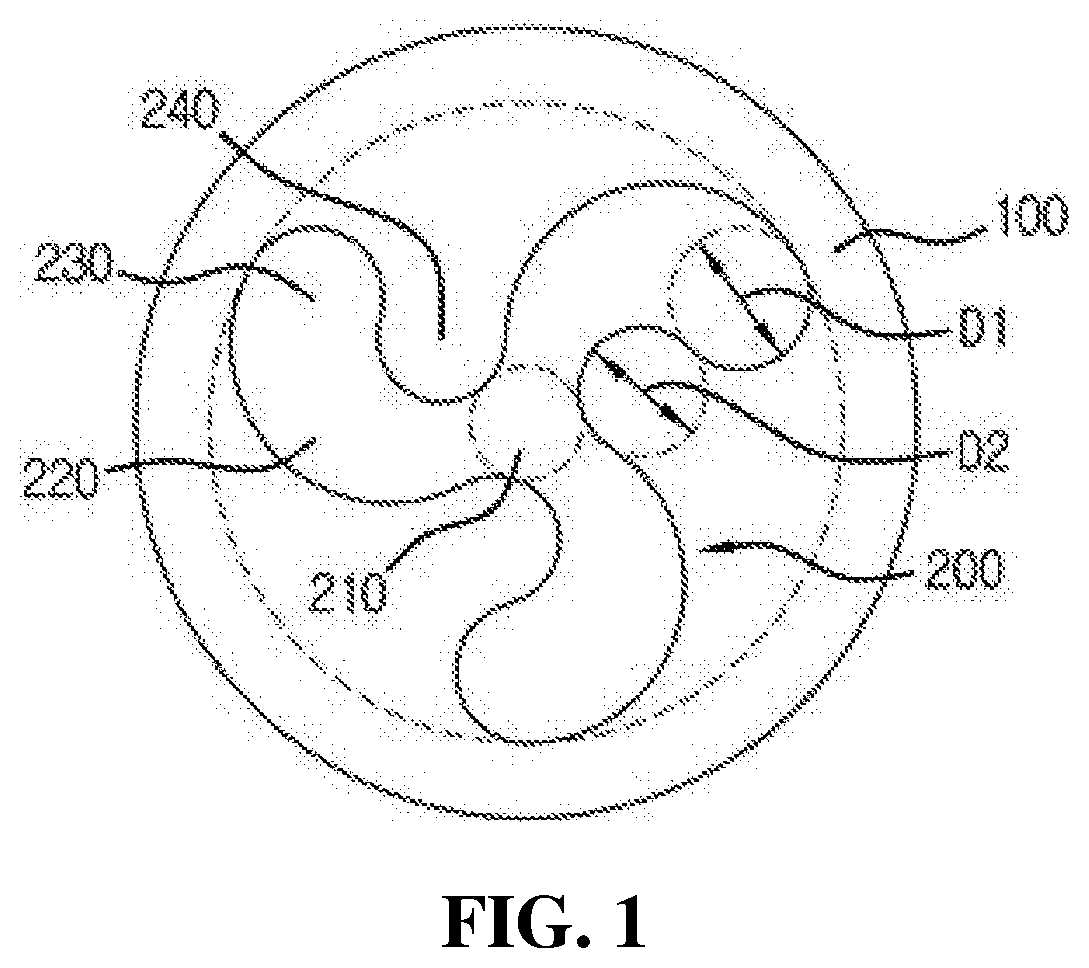

[0021]FIG. 1 is a cross-sectional view illustrating an artificial hair spinning nozzle according to an exemplary embodiment of the present disclosure.

[0022]The artificial hair spinning nozzle according to the present disclosure includes a nozzle body 100 that extends a predetermined length with a predetermined outer diameter and has a hollow spinning hole 200 that extends into the nozzle body 100 in a longitudinal direction and into which a synthetic resin is injected to longitudinally spin artificial hair. The synthetic resin injected into the spinning hole 200 uses a known polyester having excellent curl generation and retention, which is necessarily required as an artificial hair fiber.

[0023]The artificial hair spinning nozzle according to the present disclosure may be separately manufactured so that the spinning nozzle may be inse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com