Comb polymers as blocking additives for swelling clays

a clay additive and comb polymer technology, applied in the field of comb polymer, can solve the problems of increasing the cost of adding pces, and increasing the cost of high-quality river sands, and achieve the effects of reducing or preventing problems with swelling clay, reducing the negative influence of swelling clay on the effectiveness, and affecting the flowability of mineral binder compositions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

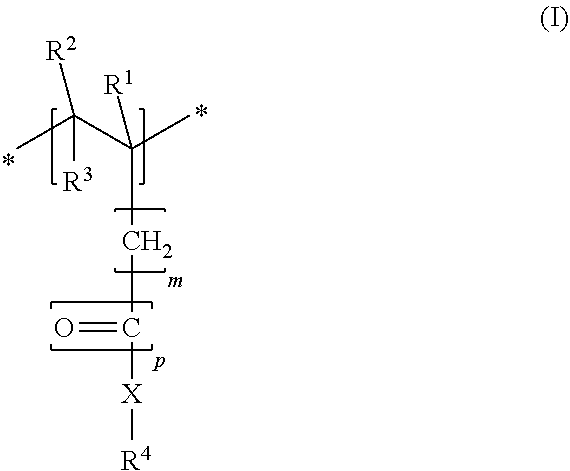

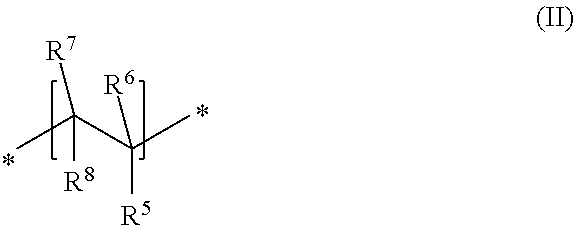

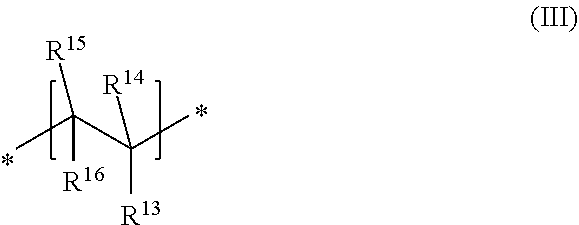

[0026]A first aspect of the invention relates to a comb polymer, in particular for use as a clay-inerting agent, comprising:[0027]a) at least one poly(alkylene oxide) side chain-bearing monomer unit M1 without ionic groups,[0028]b) optionally at least one cationic monomer unit MC,[0029]c) optionally at least one anionic monomer unit MA,[0030]d) optionally, at least one non-ionic monomer unit M3,

[0031]wherein the molar ratio of the cationic monomer units MC to the side chain-bearing monomer units M1 is equal to or less than 10, especially less than 5, the molar ratio of the anionic monomer units MA to the side chain-bearing monomer units M1 is less than 1, preferably equal to or less than 0.5, and wherein the molar ratio of the non-ionic monomer units M3 to the side chain-bearing monomer units M1 is less than 5.

[0032]Thereby, the monomer units M1, MC, MA and M3 differ from each other chemically and / or structurally. In particular, the at least one non-ionic monomer unit M3 does note c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molar ratio | aaaaa | aaaaa |

| molar ratio | aaaaa | aaaaa |

| molar ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com