Compressor and hydrogen station

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

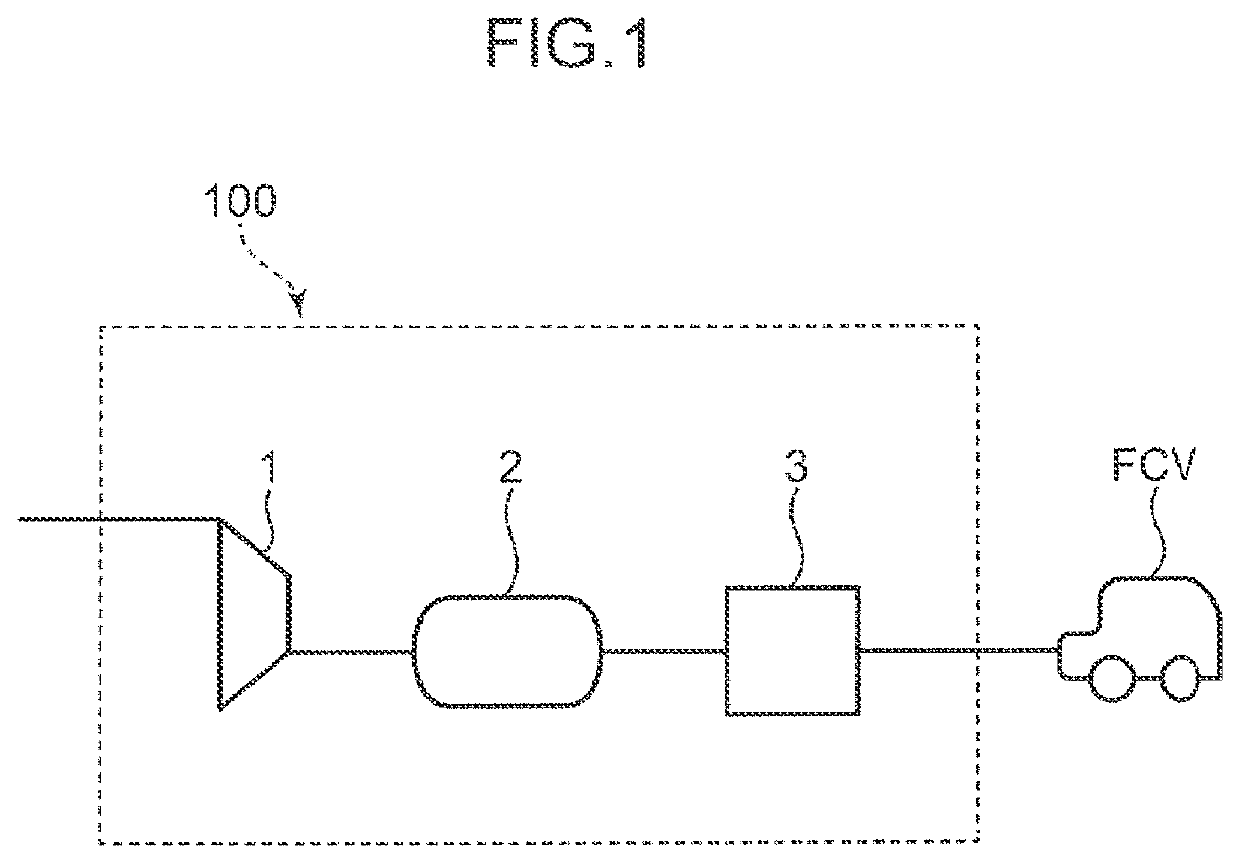

[0021]To begin with, a configuration of a hydrogen station 100 according to a first embodiment will be described with reference to FIG. 1. The hydrogen station 100 is a facility for replenishing a fuel cell vehicle (FCV) with a hydrogen gas as fuel. As shown in FIG. 1, the hydrogen station 100 includes a compressor 1 for compressing a hydrogen gas, an accumulator 2 for storing the high-pressure hydrogen gas compressed by the compressor 1 and then discharged from the compressor 1, and a dispenser 3 for receiving supply of the high-pressure hydrogen gas from the accumulator 2 and supplies the high-pressure hydrogen gas to a demand destination such as a fuel cell vehicle.

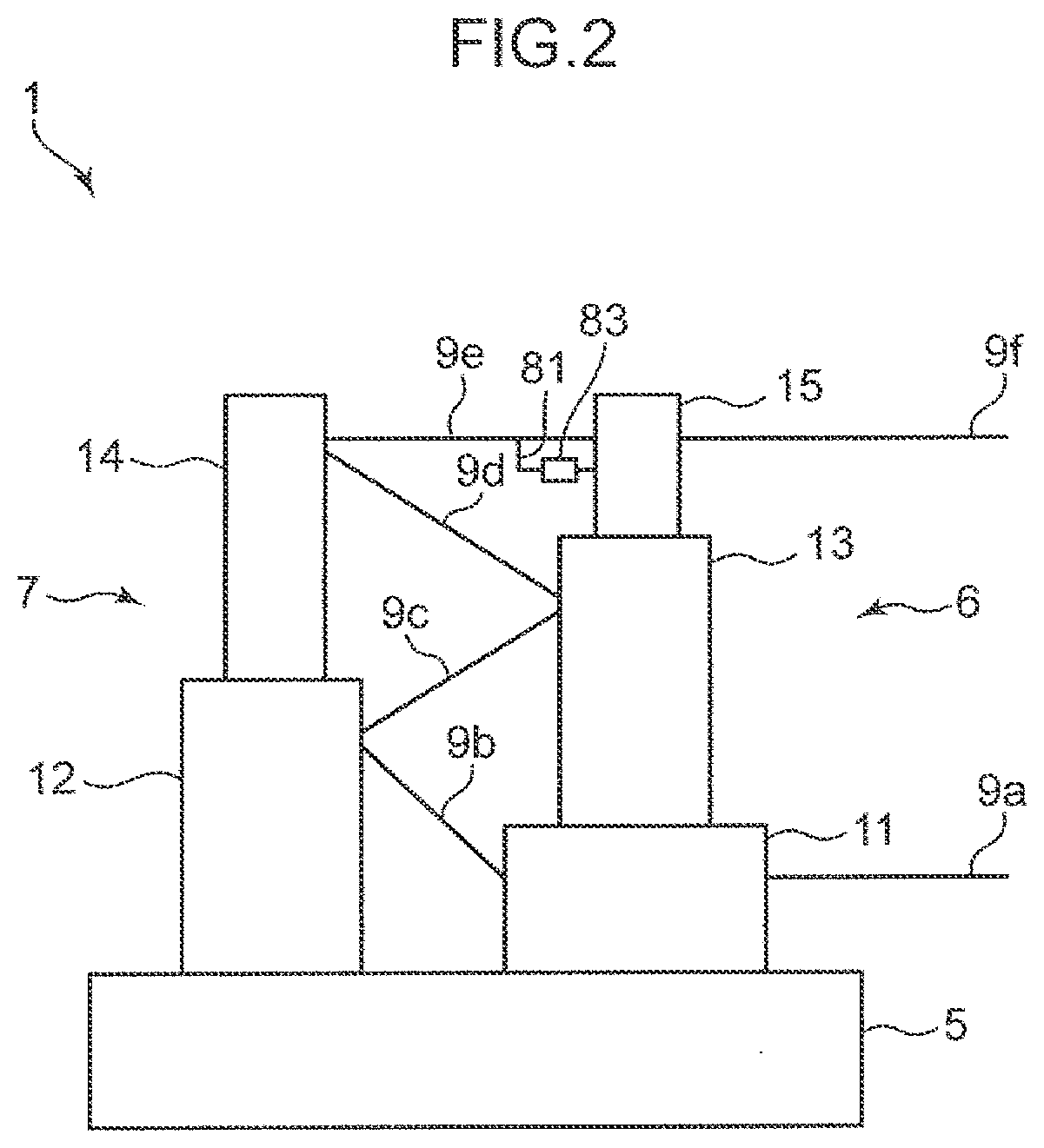

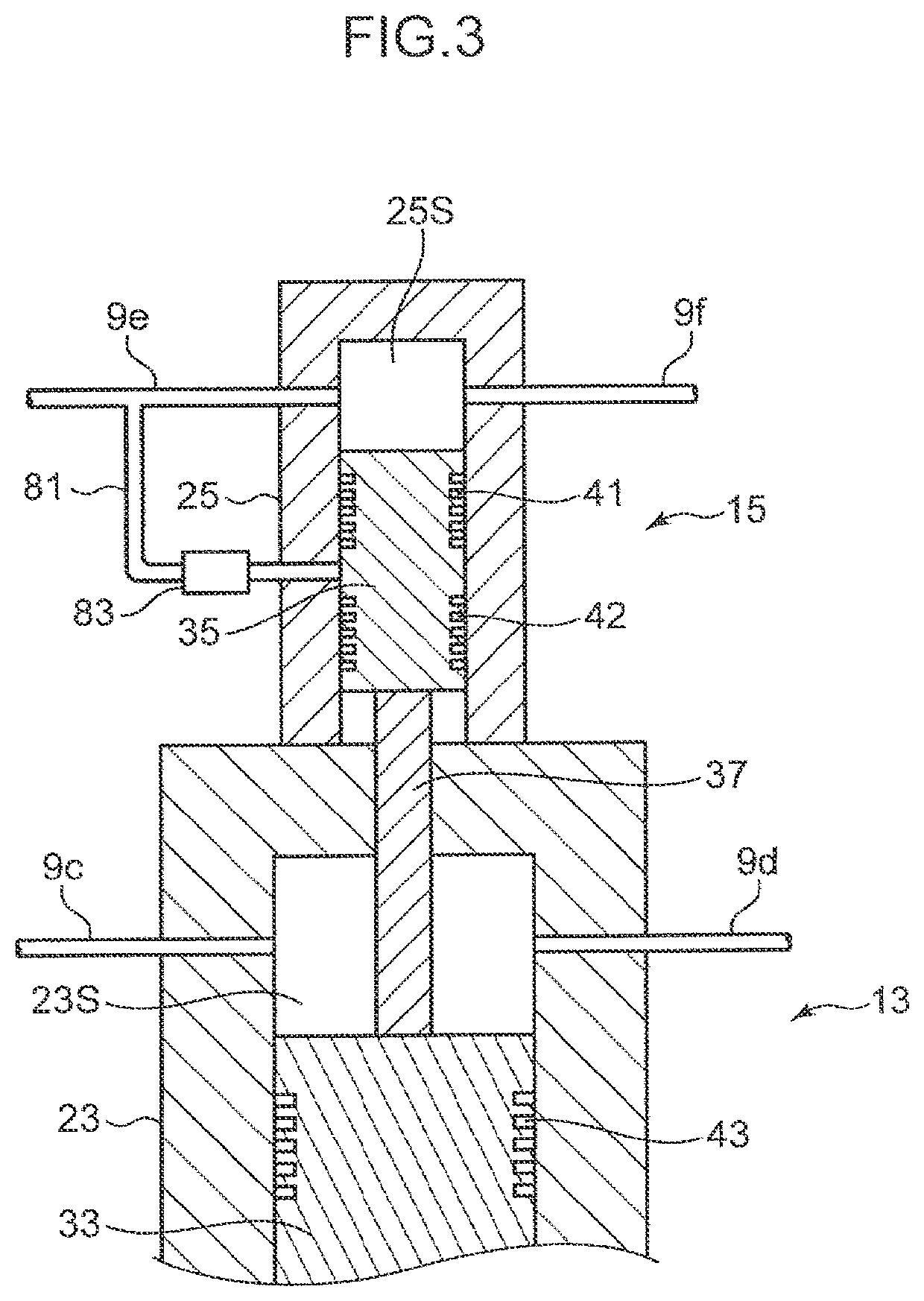

[0022]Next, a configuration of the compressor 1 will be described with reference to FIGS. 2 to 4. As shown in FIG. 2, the compressor 1 includes a plurality of compression stages (first to fifth compression stages 11 to 15) and a drive mechanism 5 that drives the plurality of compression stages 11 to 15. Each of the fiv...

second embodiment

[0054]Next, a compressor according to a second embodiment will be described. The compressor according to the second embodiment is basically similar to the compressor 1 according to the first embodiment, but differs in a configuration of a volume expansion unit. Only differences from the first embodiment will be described below.

[0055]FIG. 5 is a diagram schematically showing a configuration of a leak line 81a in the second embodiment. As shown in FIG. 5, the leak line 81a includes a volume expansion unit 83a connected to a piping part 82, and the volume expansion unit 83a includes a meandering pipe. The volume expansion unit 83a has a length in a range 84 of a predetermined distance longer than the length of the linear piping part 82 in the same distance range 84. Therefore, the volume in the range 84 is larger than the volume of the piping part 82 in the same range 84. That is, when the volume expansion unit 83 is compared with the piping part 82, the volume expansion unit 83 is lar...

third embodiment

[0056]Next, a compressor according to a third embodiment will be described. The compressor according to the third embodiment is basically similar to the compressor 1 according to the first embodiment, but differs in a configuration of a volume expansion unit. Only differences from the first embodiment will be described below.

[0057]FIG. 6 is a diagram schematically showing a configuration of a leak line 81b in the third embodiment. As shown in FIG. 6, the leak line 81b includes a volume expansion unit 83b connected to a piping part 82, and the volume expansion unit 83b includes a pipe formed in a spiral shape. The volume expansion unit 83b has a length in a range 84 of a predetermined distance longer than the length of the linear piping part 82 in the same distance range 84. Therefore, the volume in the range 84 is larger than the volume of the piping part 82 in the same range 84. A first piping part 82a is connected to one end of the volume expansion unit 83b, and a second piping pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com