Oxidation heat treatment oven and method for manufacturing oxidized fiber bundle and carbon fiber bundle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

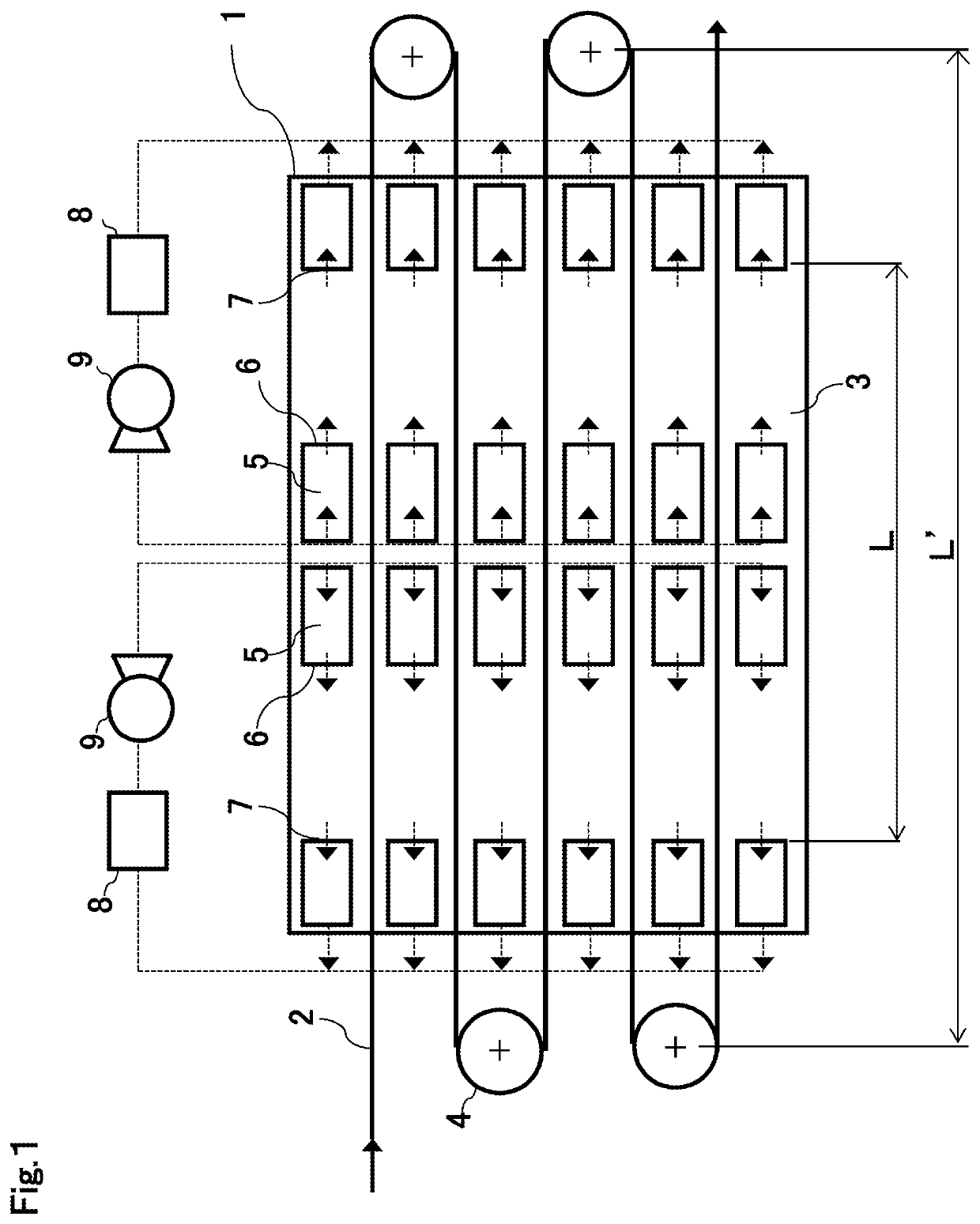

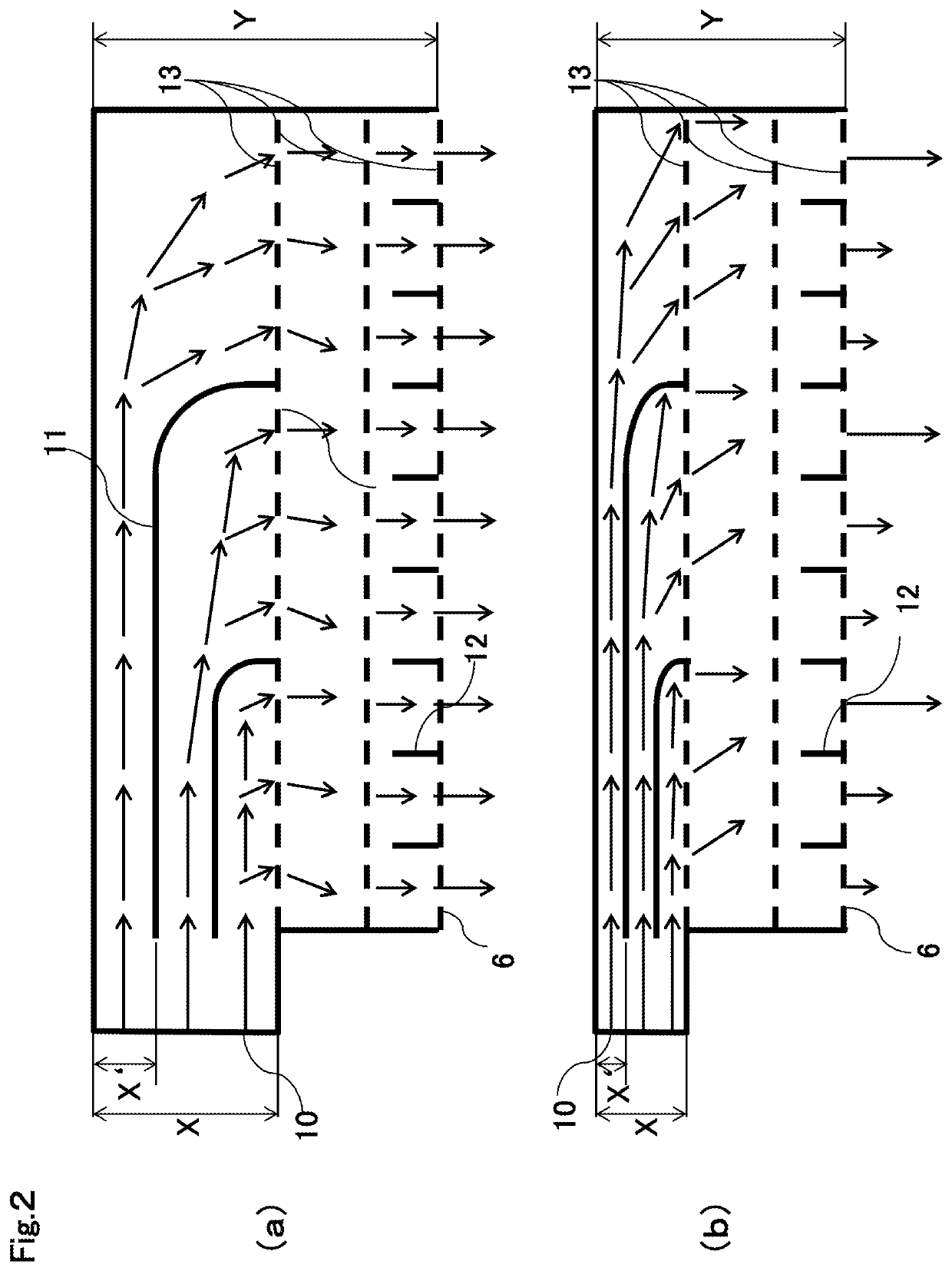

[0084]FIG. 1 is a schematic configuration diagram showing an example when the heat treatment oven according to an embodiment of the present invention is used as an oxidation oven for carbon fiber manufacturing. At centers between the guide rollers 4 on both sides of the oxidation oven 1, the hot air supply nozzles 5 are installed above and below the acrylic fiber bundle 2 traveling in the oxidation oven 1. The hot air supply nozzle 5 was provided with the hot air supply port 6 in a traveling direction of the fiber bundle or in a direction opposite to the traveling direction of the fiber bundle.

[0085]For the acrylic fiber bundle 2 that travels in the oven, 100 fiber bundles each composed of 20,000 single fibers having a single fiber fineness of 0.11 tex were aligned and heat-treated in the oxidation oven 1 to obtain an oxidized fiber bundle. The horizontal distance L′ between the guide rollers 4 on both sides of the heat treatment chamber 3 of the oxidation oven 1 was 15 m, the guide...

example 2

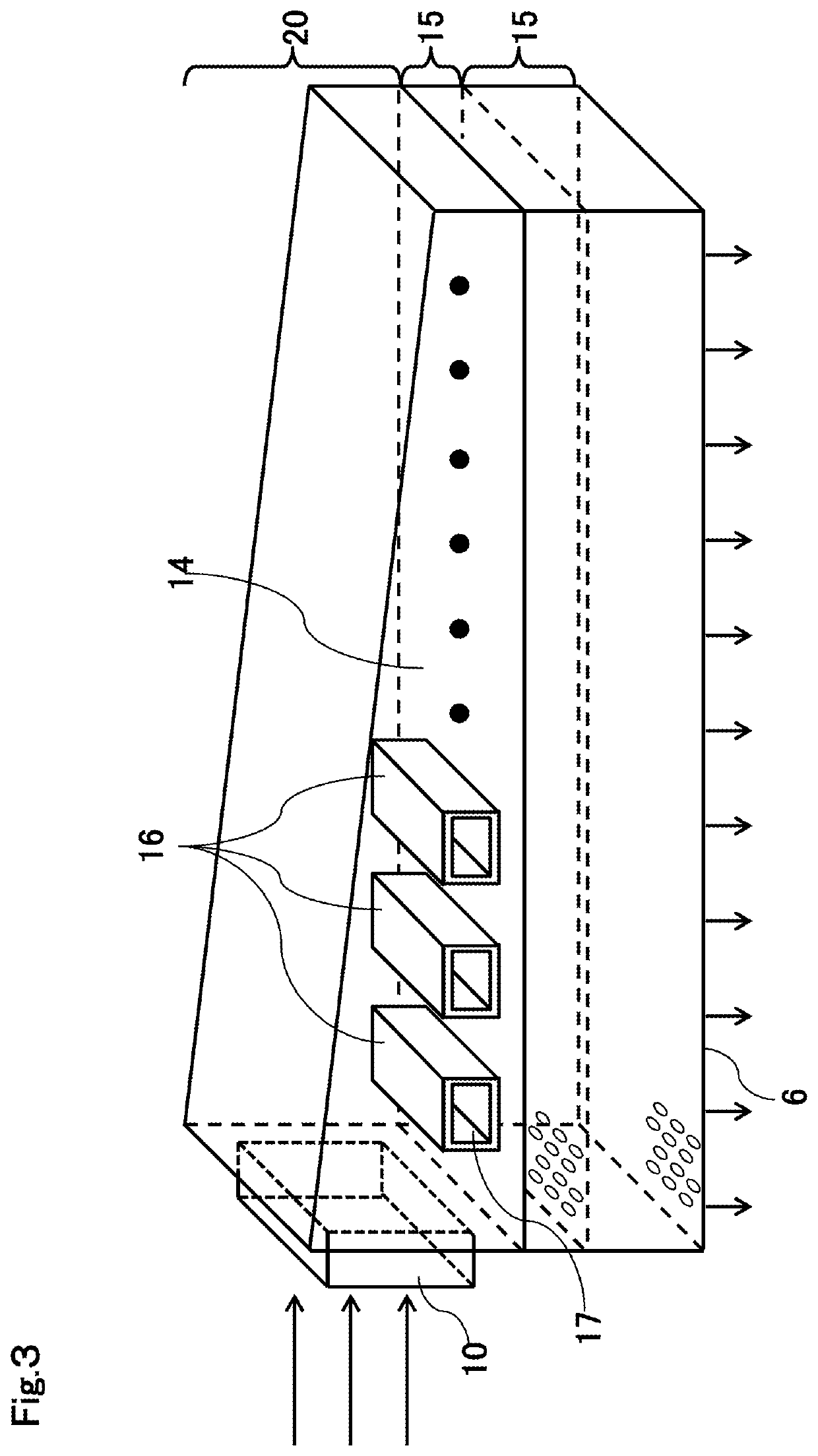

[0089]The procedure similar to that of Example 1 was carried out except that, in the hot air supply nozzle 5 shown in FIGS. 3, 4, and 5, the internal angle θ was 90°, and the interval S between the adjacent cylindrical bodies was reduced to 5 mm. In this case, the air speed variation was 8.6%. Under the above conditions, fiber mixing, fiber bundle breakage, or the like due to contact between the fiber bundles did not occur at all during the oxidation treatment of the acryl fiber bundle, and an oxidized fiber bundle was acquired with extremely good process stability. In addition, the obtained oxidized fiber bundle and carbon fiber bundle were visually checked, and the result showed that the quality was extremely good without fuzz or the like.

example 3

[0090]The procedure similar to that of Example 2 was carried out except that an interval S between adjacent cylindrical bodies was 0 mm. In other words, in this configuration, all the cylindrical bodies are connected to the partition plate so that the cylindrical bodies are in contact with each other, and the gas flow hole 18 is a slit extending along the longitudinal axis of the nozzle. In this case, the air speed variation was 8.2%. Under the above conditions, fiber mixing, fiber bundle breakage, or the like due to contact between the fiber bundles did not occur at all during the oxidation treatment of the acryl fiber bundle, and an oxidized fiber bundle was acquired with extremely good process stability. In addition, the obtained oxidized fiber bundle and carbon fiber bundle were visually checked, and the result showed that the quality was extremely good without fuzz or the like.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com