Vehicle window glass holder

a technology for window glass and holder, which is applied in the direction of wing accessories, couplings, rod connections, etc., can solve the problems of difficult to remove the rivet, easy breakage of the window glass, and difficulty in removing the holder from the window glass, so as to facilitate the fixing of the window glass and the easy extraction of the shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

(First Embodiment)

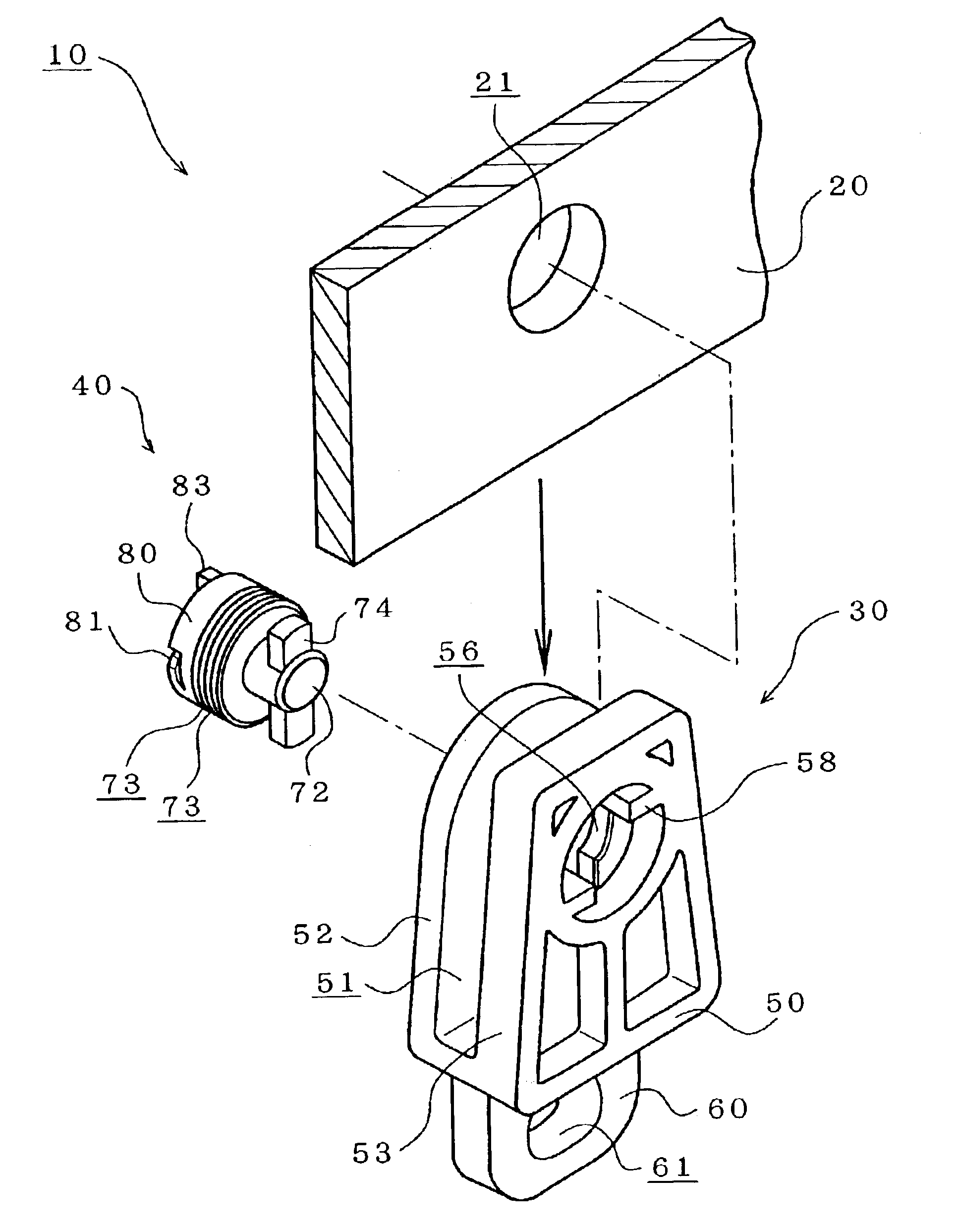

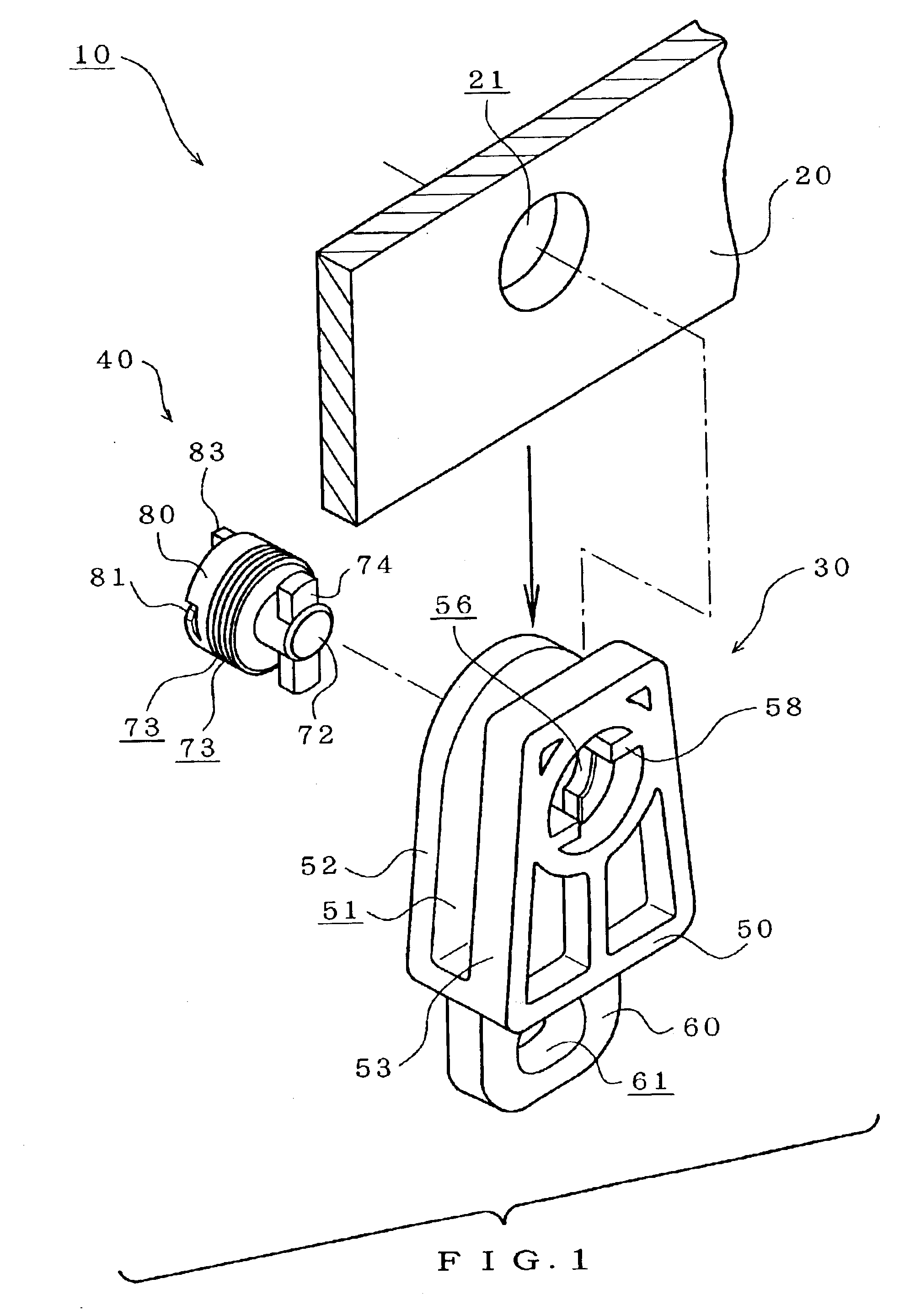

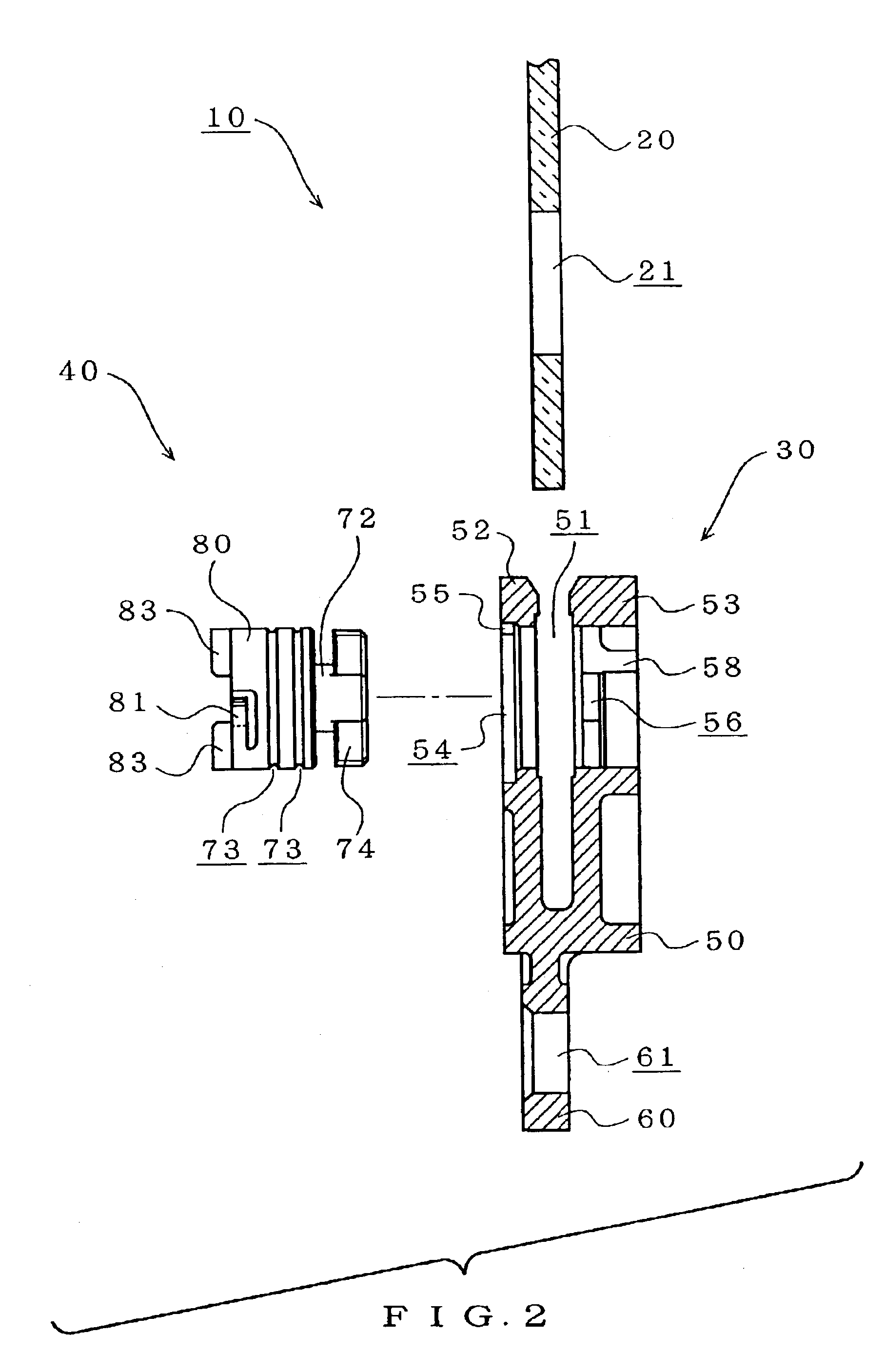

Now, description will be made of a holder according to a first embodiment of the present invention with reference to FIGS. 1 to 16. As shown in FIGS. 1 and 2, a holder 10 comprises a holding member 30 and a shaft 40. As shown in FIGS. 1 to 3, the holding member 30 includes portion 51 into which a window glass 20 is inserted (referred to as a window glass inserting portion hereinafter). As shown in FIGS. 3 to 7, the holding member 30 also includes a main body 50, and a connecting portion 60. Such holding member 30 is integrally formed by using a thermoplastic resin, for example, nylon, having proper rigidity.

As shown in FIGS. 1 and 2, the shaft 40 is designed to fix the window glass 20 in the window glass inserting portion 51 of the holding member 30. As shown in FIGS. 8 to 11, the shaft 40 includes two projecting pieces 74 provided on its tip, a support portion 72 for supporting the projecting pieces, and a main body 80. Such shaft 40 is integrally formed by using ...

second embodiment

(Second Embodiment)

Next, description will be made of a holder according to a second embodiment of the present invention. The first embodiment is directed to the reverse-rotation preventing mechanism based on the locking of the elastic piece 81 provided at the end of the shaft 40 with the tapered step 55 provided on the inner peripheral surface of the shaft inserting hole 54 of the holding member main body.

The second embodiment is directed to a reverse-rotation preventing mechanism based on the locking of an elastic piece protruded from each of projecting pieces provided at the tip of the shaft with a recess provided at the peripheral part of the shaft inserting hole 56 of the holding member main body.

FIG. 18 is an exploded perspective view illustrating the holder of the second embodiment, and FIG. 19 a right side view of the holding member. An elastic piece 75 is integrally formed on a projecting piece 74 provided at the tip of the shaft 40, the elastic piece being opposed to the sh...

third embodiment

(Third Embodiment)

Next, description will be made of a third embodiment of the present invention by referring to FIGS. 20 and 21. According to the embodiment, as shown in FIGS. 20 and 21, a buffer member 90 is fixed to the bottom surface of the window glass inserting portion 51 of the holding member 30. As shown in FIG. 20, the buffer member 90 is sheet-shaped. A horizontal width of the buffer member 90 is set so as to be larger than the width of the window glass inserting portion 51. A total length of the buffer member 90 is set so as to be equal to or lower than the length of the portion 51. A felt sheet material, for example, can be used for the buffer member 90. The material of the buffer member 90 is not limited to such felt, and rubber or sponge may be used.

When the buffer member 90 is inserted into the window glass inserting portion 51, as shown in FIG. 21, the buffer member 90 is bent in a U-shape along the bottom surface of the portion 51. Accordingly, even when a force is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com