Compact packaging of multiple fiber lasers

a technology of fiber lasers and compact packaging, applied in the field of fiber packaging, can solve the problems of limited size, large volume inside the spool, and generally circular shape of the spool, and achieve the effect of small volum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]The following description of the preferred embodiments is merely exemplary in nature and is in no way intended to limit the invention, its application, or uses.

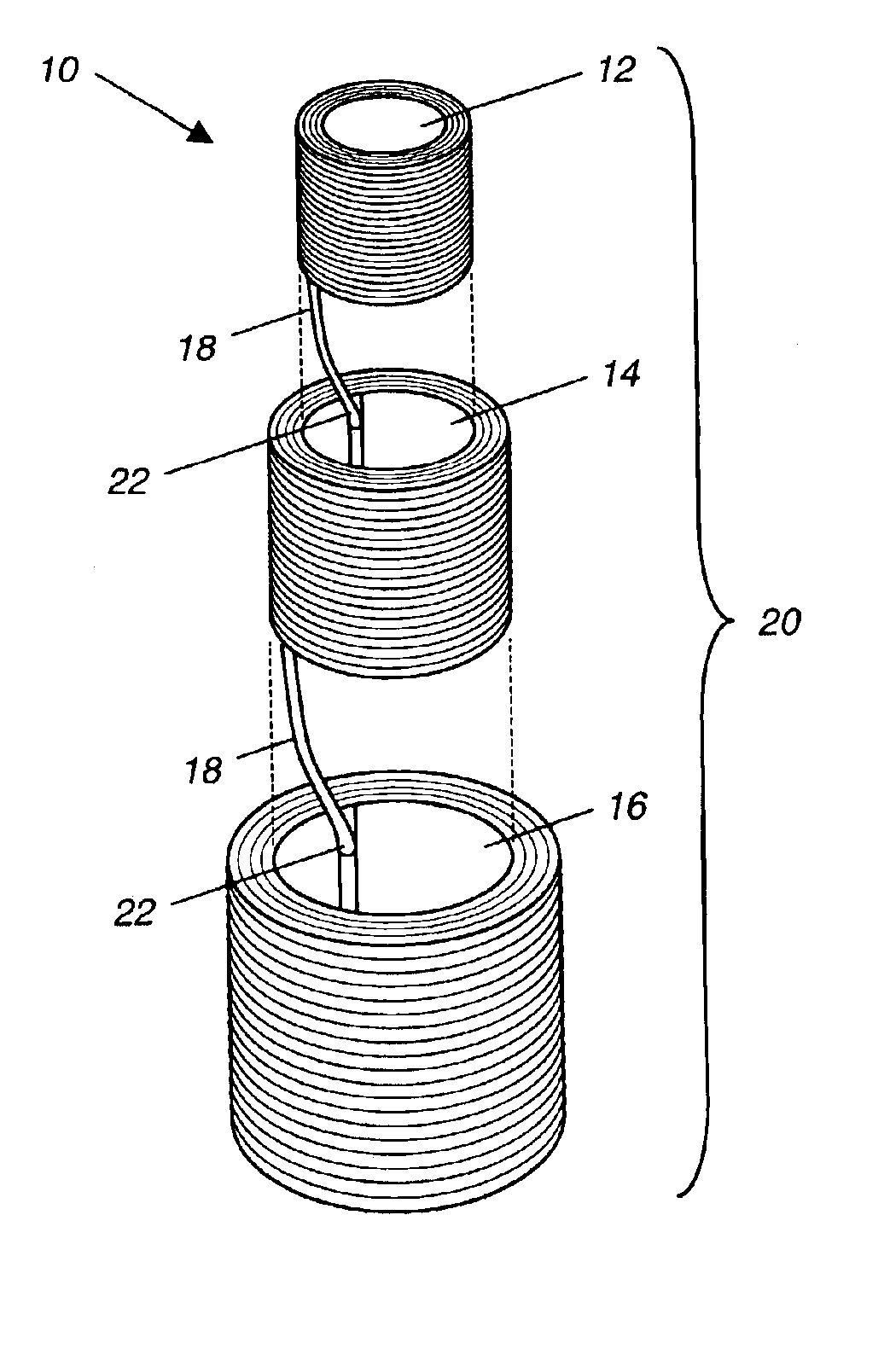

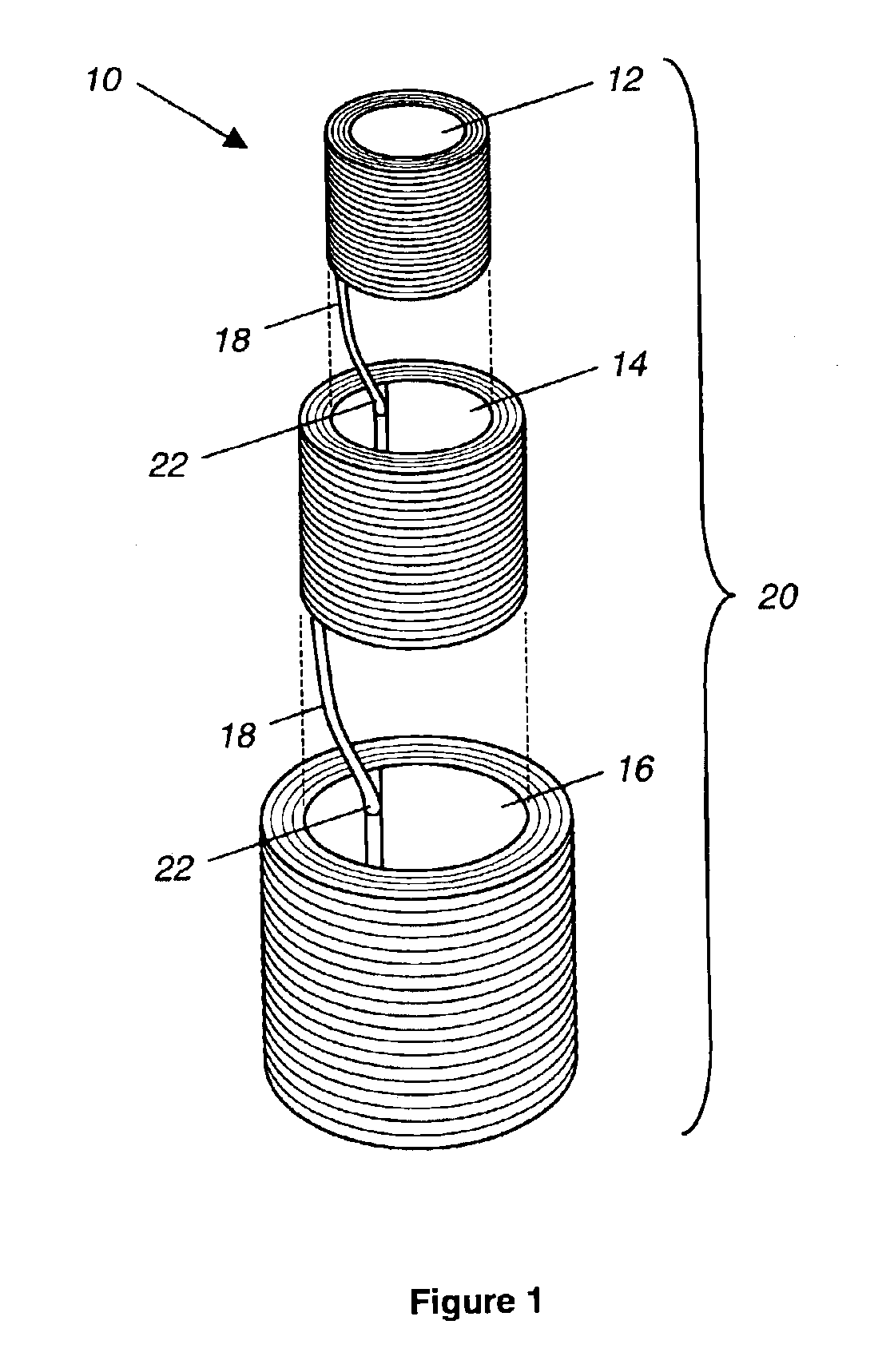

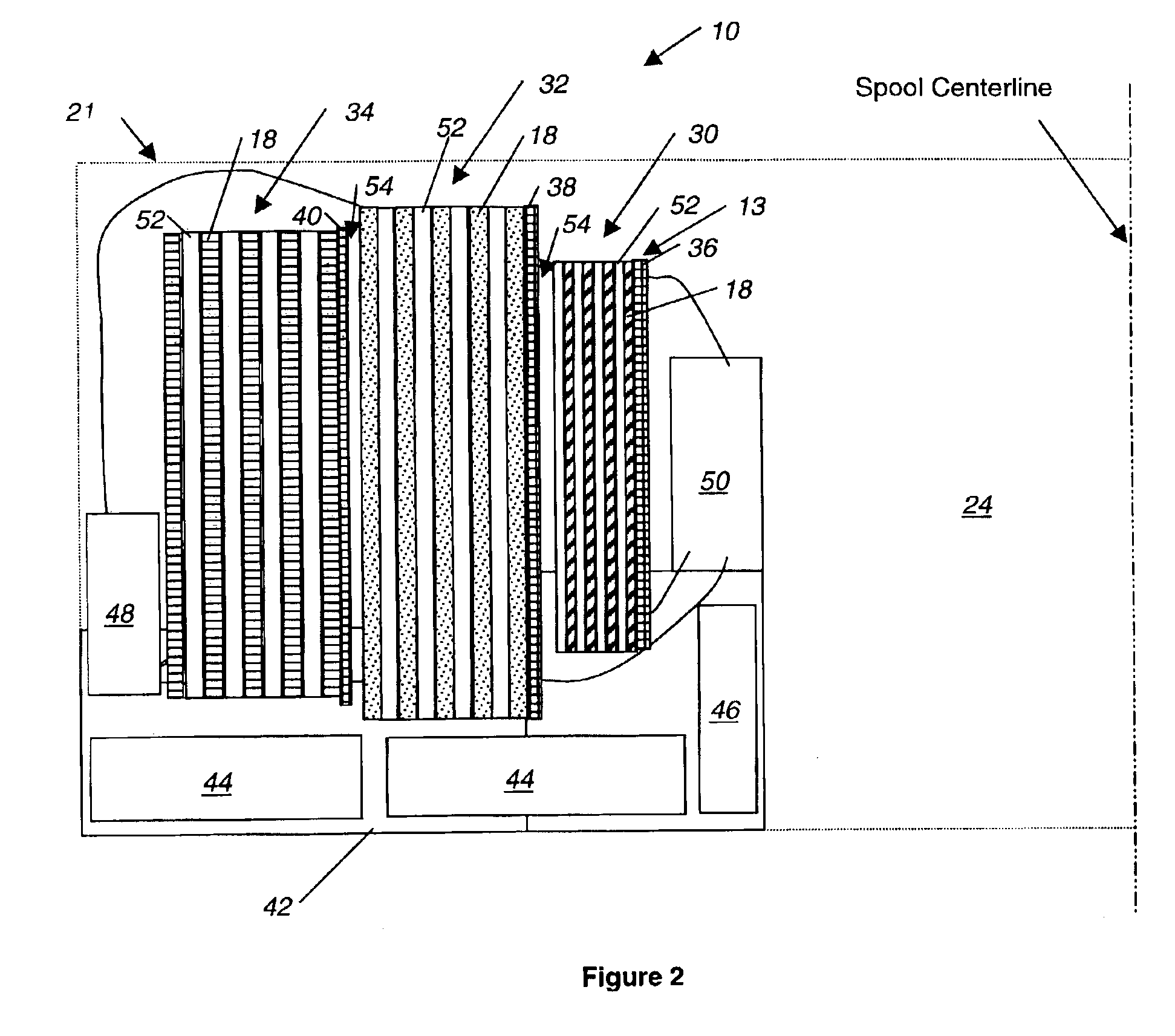

[0020]Referring to FIG. 1, the compact fiber packaging system of the present invention is illustrated and generally indicated as reference numeral 10. The compact fiber packaging system 10 generally comprises an inner spool 12 nested inside a first outer spool 14, which is nested inside a second outer spool 16. As shown, the outer diameter of inner spool 12 is slightly smaller than the inner diameter of first outer spool 14, and similarly, the outer diameter of first outer spool 14 is slightly smaller than the inner diameter of second outer spool 16. Accordingly, the spools may be nested inside one another for efficient volume utilization.

[0021]As shown, the fibers 18 are wrapped around the inner spool 12 and then successively around the first outer spool 14 and then the second outer spool 16 to form a module 20, wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com