Micromechanical flow sensor with tensile coating

a micromechanical and flow sensor technology, applied in the field of sensors, can solve problems such as change or degradation of the function of these components, and achieve the effect of preventing buckling of the membran

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

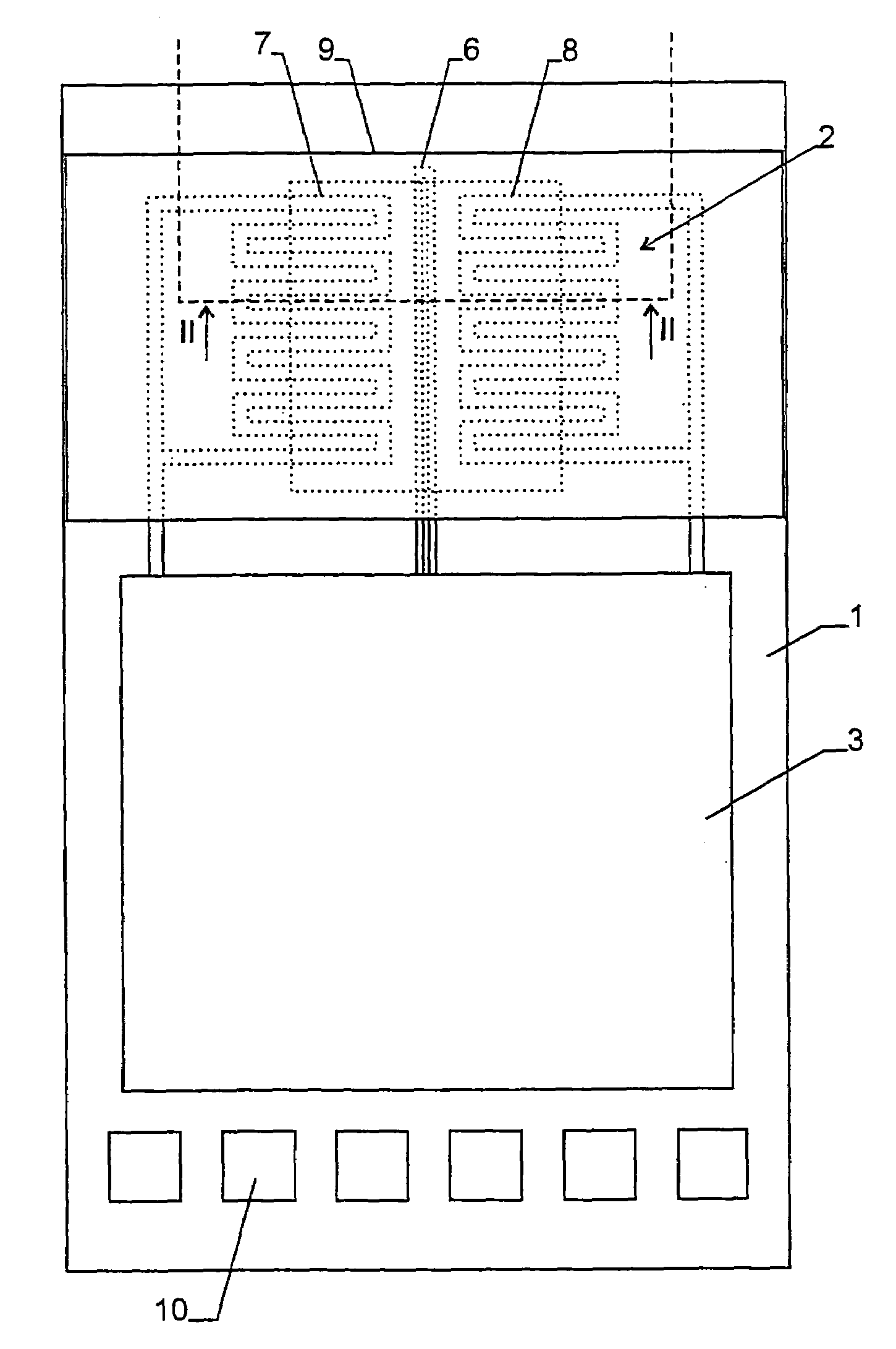

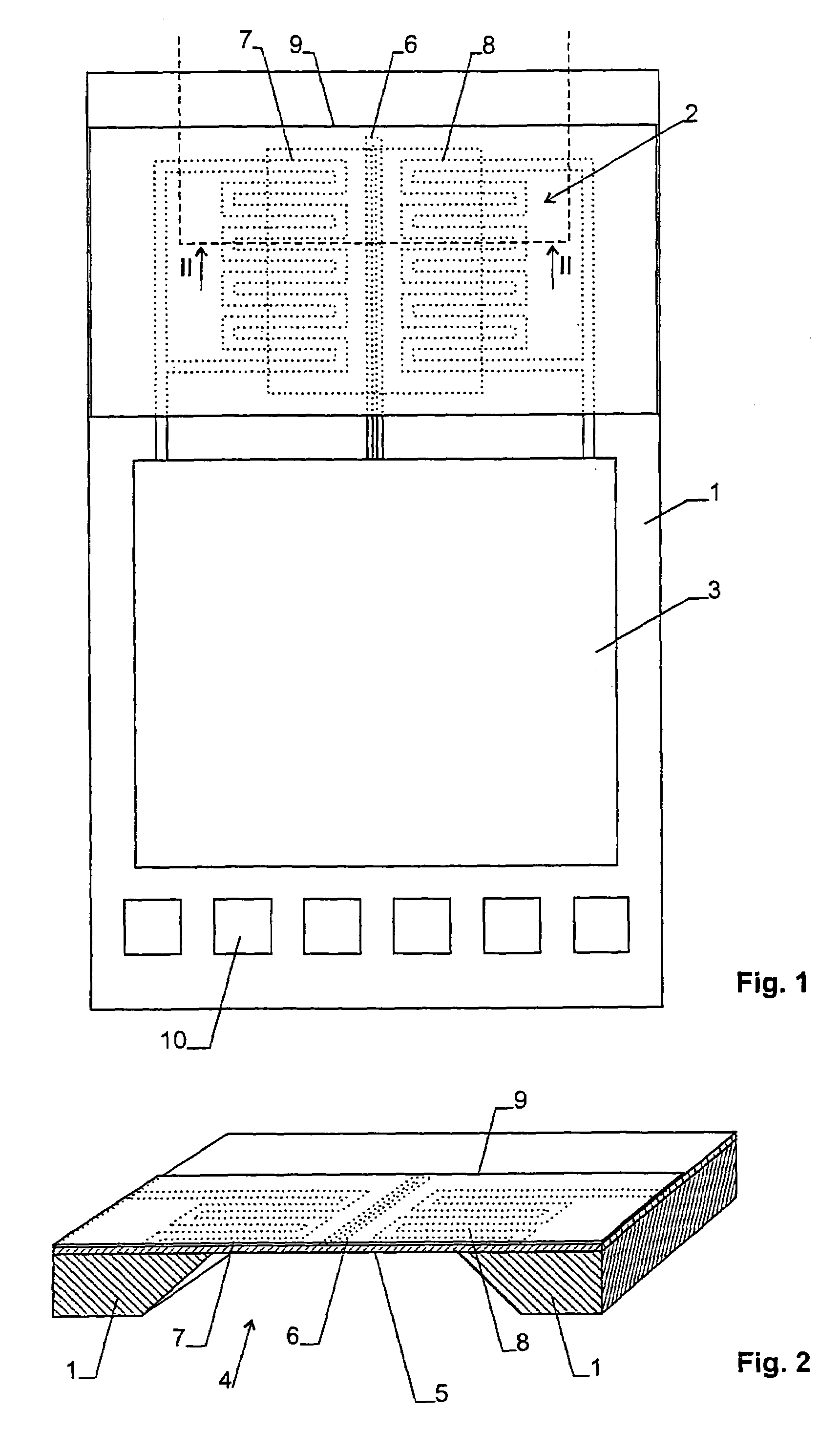

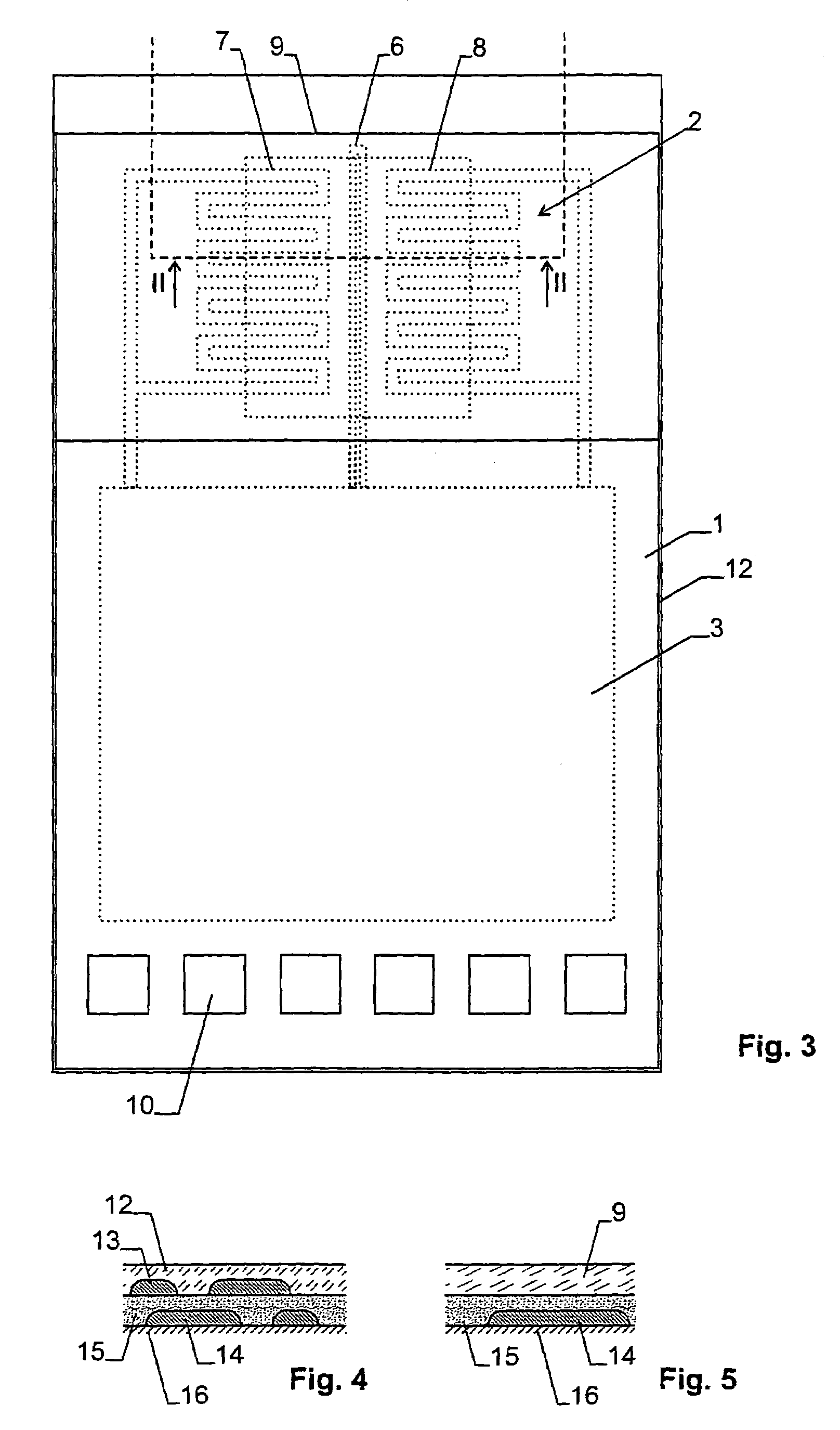

[0016]In FIGS. 1 and 2 an embodiment of the invention in the form of a flow sensor is shown. It comprises a semi-conductor device 1, onto which a measuring element 2 and a circuit 3 are integrated.

[0017]In semiconductor device 1 an opening or recess 4 has been etched out, which is covered by a thin membrane 5.

[0018]A heating 6 is arranged on membrane 5. Two meandering thermopiles 7, 8 are provided symmetrically to heating 6, which act as temperature sensors. The orientation of the thermopiles 7, 8 and the heating 6 in respect to the flow direction of the medium to be measured is such that the medium first flows over first thermopile 7, then over heating 6, and finally over second thermopile 8.

[0019]The measuring element 2 is covered by a tensile coating 9, which is under tensile stress and extends beyond membrane 5 on all sides or at least on two opposite sides of recess or opening 4. The overlap reaches at least sufficiently far in order to provide anchoring for the tensile coating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com