Method for reducing argon diffusion from high density plasma films

a plasma film and high density technology, applied in the field of forming semiconductor devices, can solve the problems of metal interconnect structures that cannot be used at the temperature, metal defects that get buried in ild films, and the inability to handle wiring requirements, etc., to reduce the number of metal defects, reduce the amount of metal defects, and reduce the content of die argon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

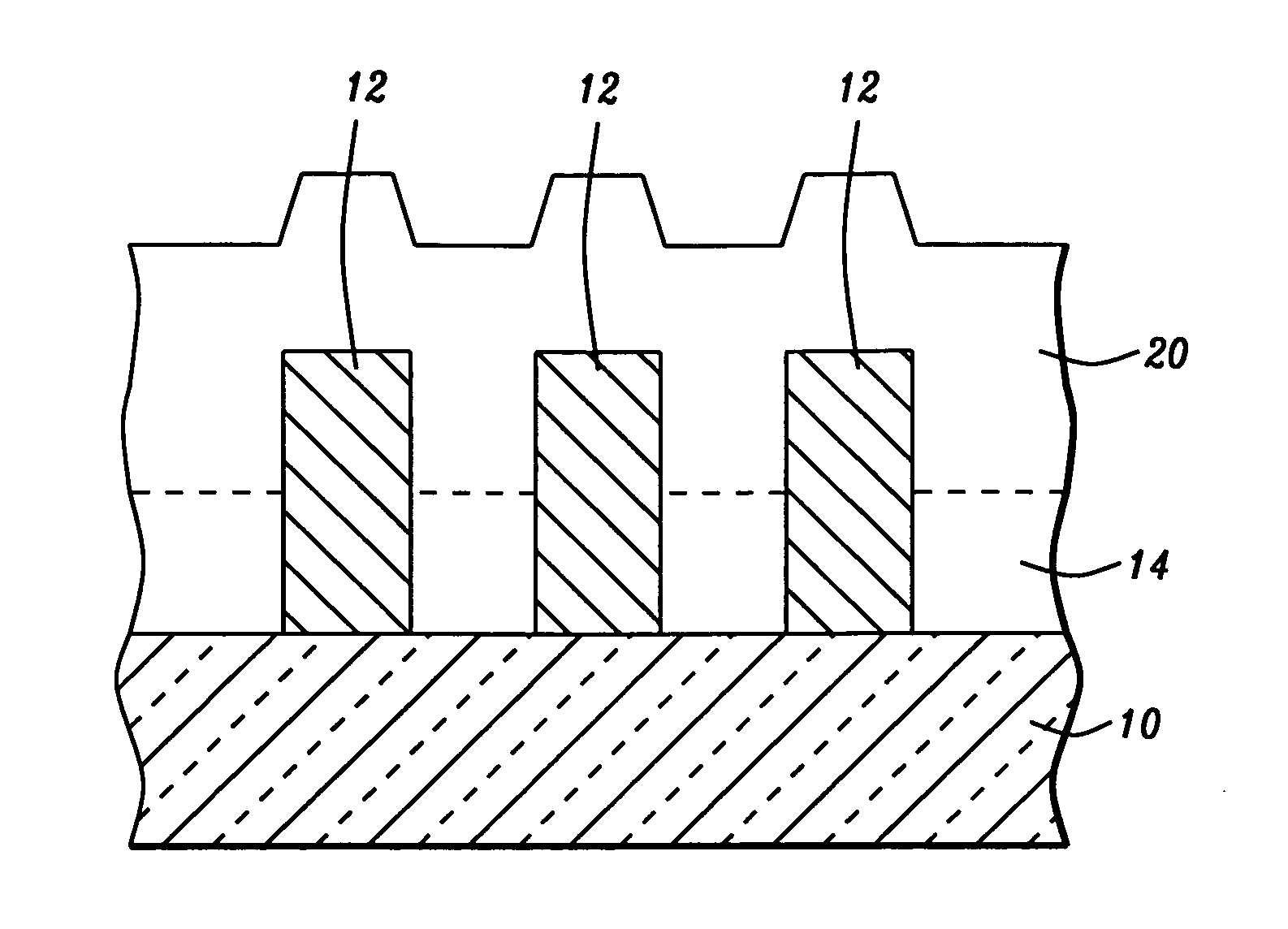

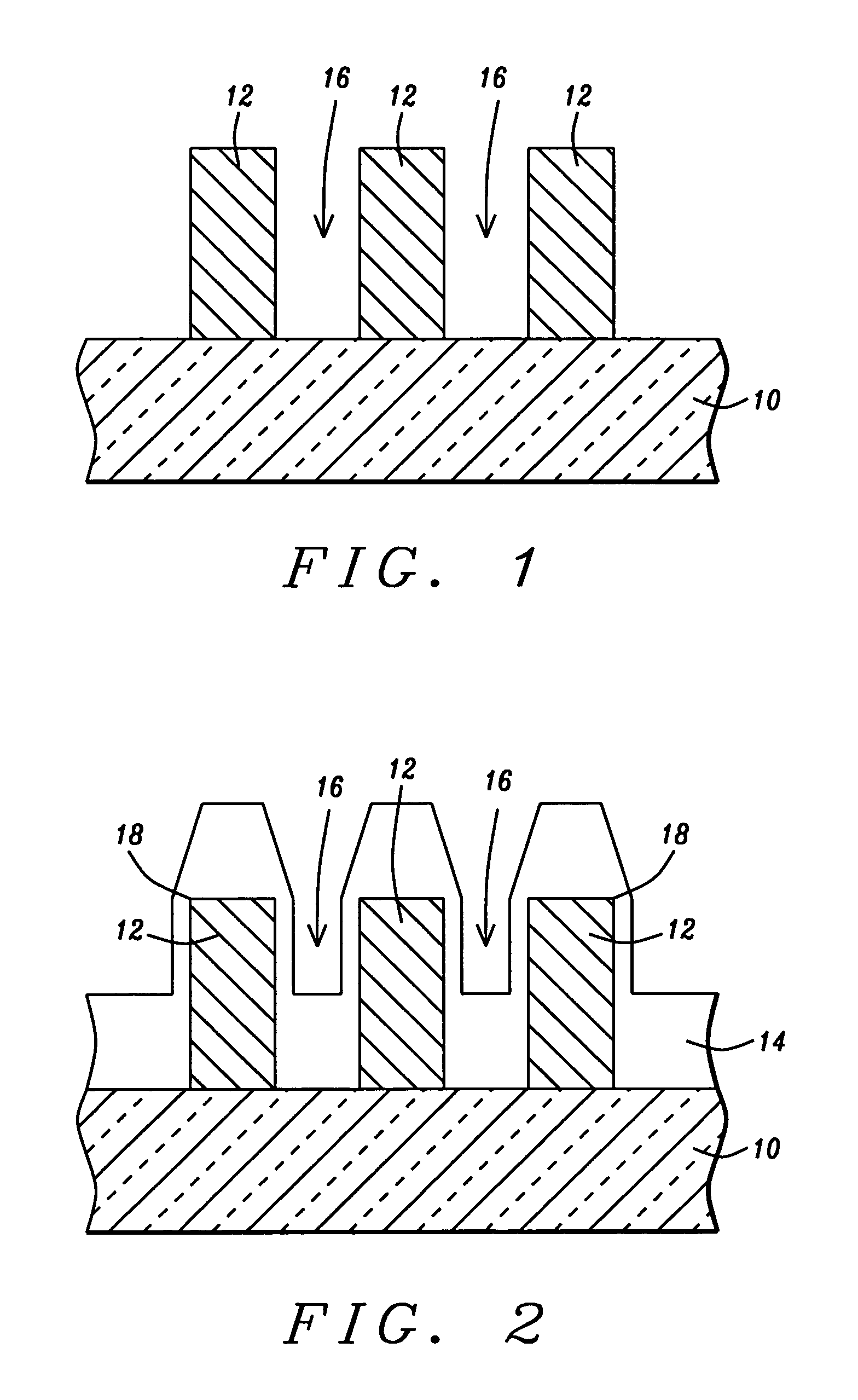

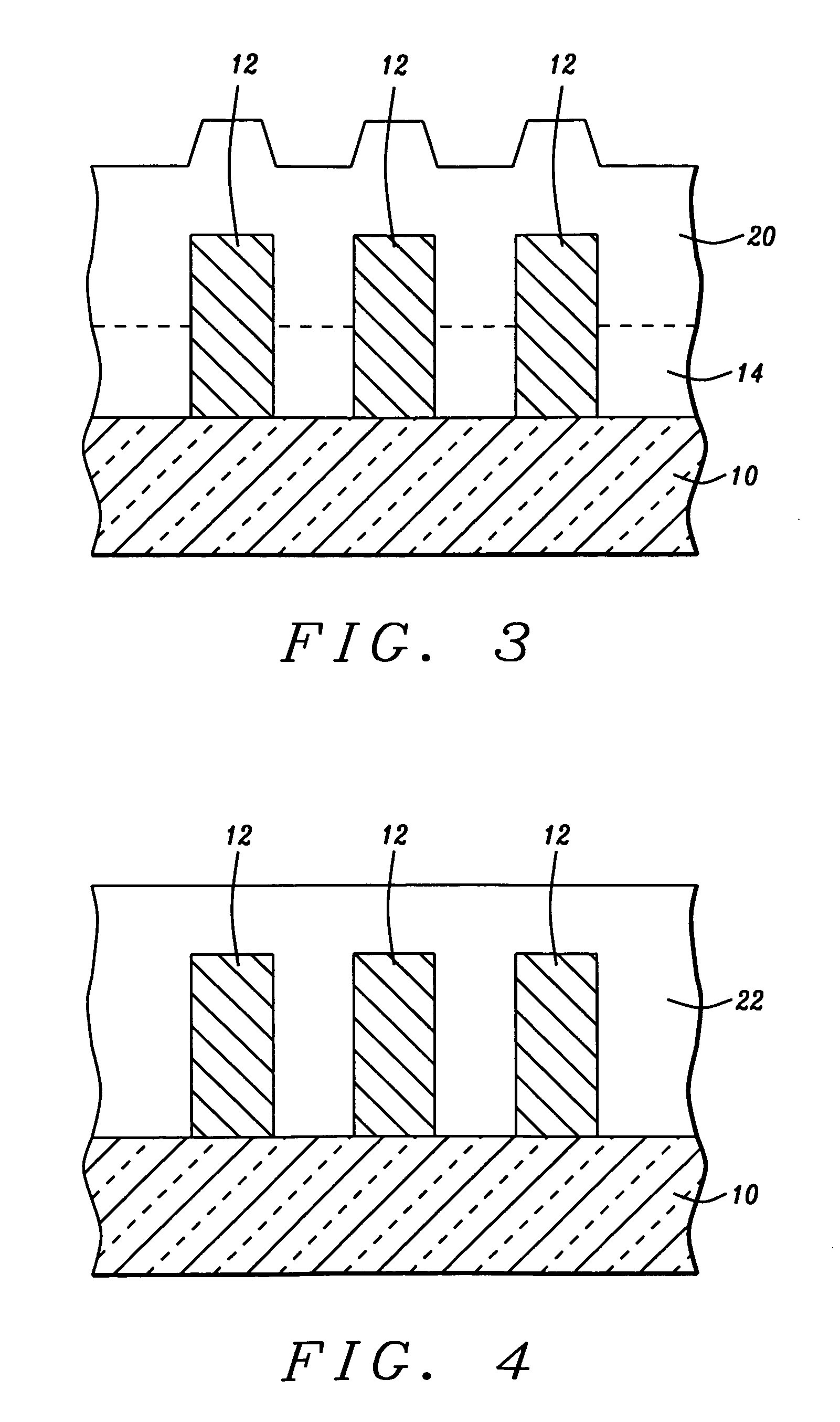

[0018]A first HDP-CVD inter level dielectric film 14 is then deposited, with the object of filling the gaps 16 between metal lines. HDP-CVD method is chosen since the film can be deposited at less than 400 C and the film quality is superior in terms gap-filling characteristics, density, and pinholes. Since the HDP-CVD is a plasma deposition method, it has both deposition and sputter etching components built-in. By controlling the ratio of sputter etching (E) and deposition (D) components, it is possible to tailor the properties of the films and gap-filling characteristics. For example, while filling high aspect ratio (height-to-gap width) gaps the openings of the gaps can get closed prematurely and produce large voids or key holes in the deposited film. By adjusting the etching component in the process, the gap openings can be kept open to achieve a more bottom-up filling. Too much of the etching component can result in metal line corner faceting since sputter etching can also erode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com