Vehicular lamp

a technology of vehicle lamps and lampshades, which is applied in the direction of fixed installation, lighting and heating apparatus, and support devices for lighting, etc., can solve the problems of not easy melting of snow and ice on the outer surface of the outer lens, and not a great deal of heat generation by light-emitting diodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

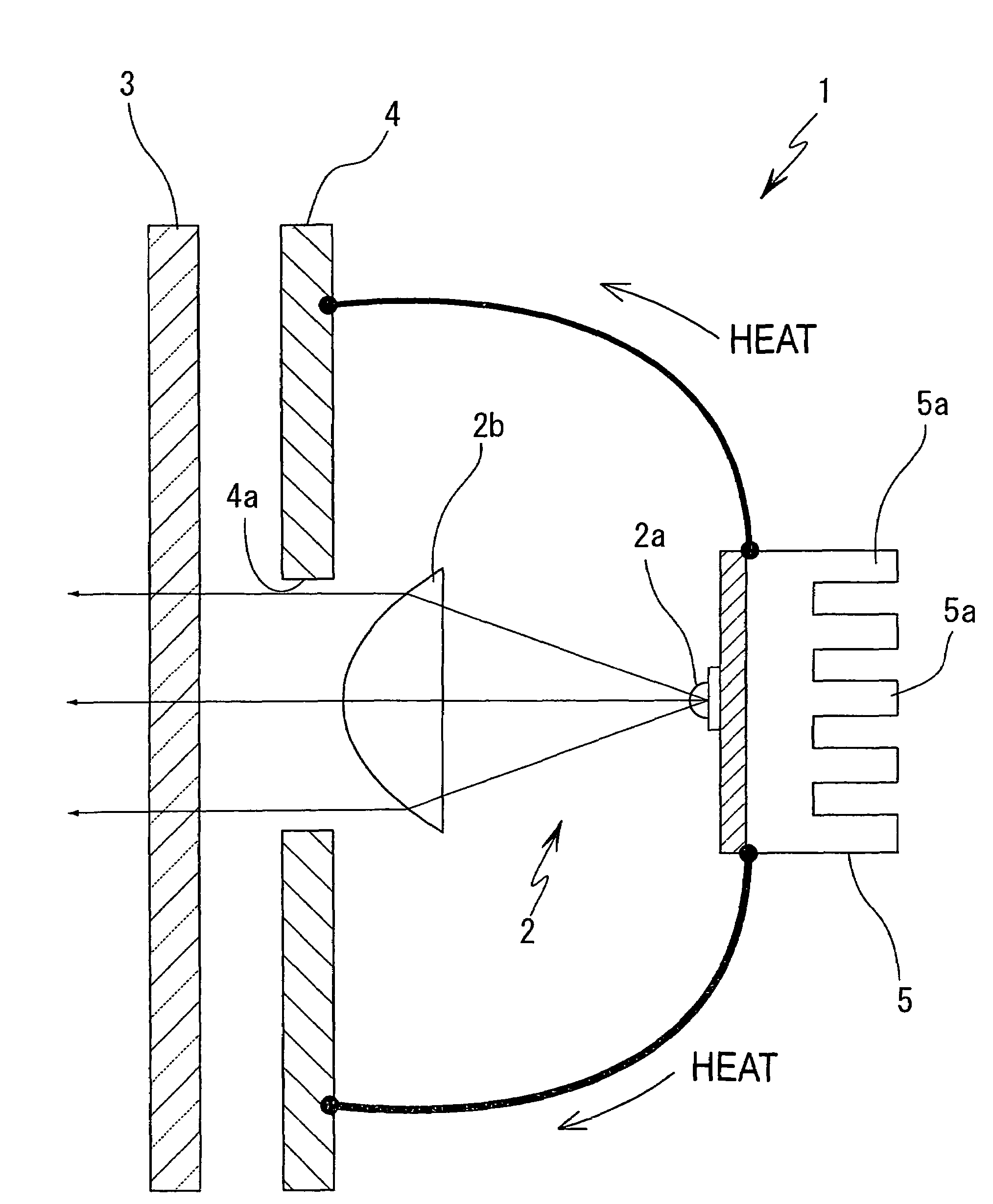

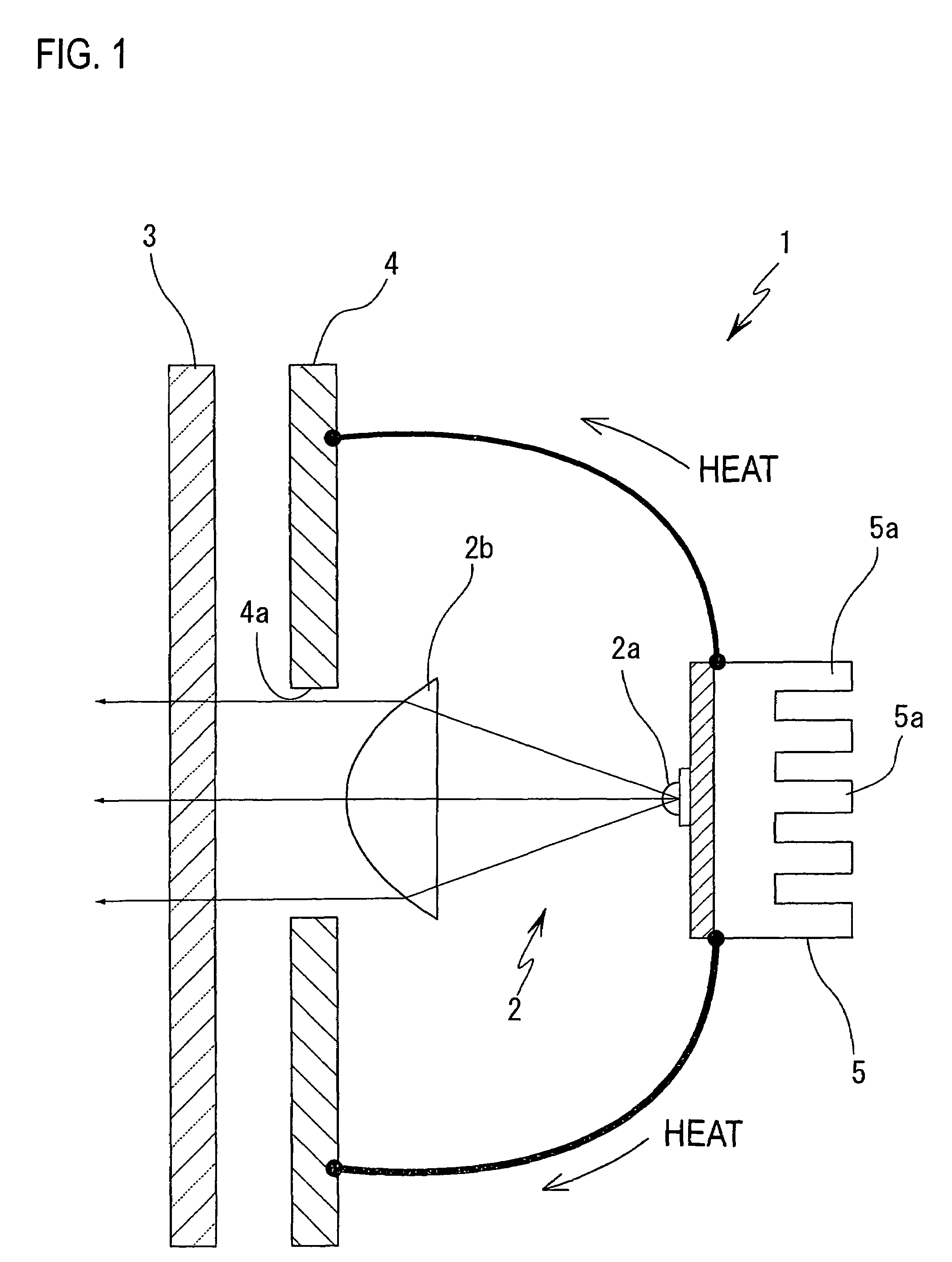

[0020]In the present invention, a vehicular lamp that uses a light-emitting diode as its light source melts the snow and ice on the outer lens by actively using the heat generated by the light-emitting diode, thus preventing the decrease in the illumination performance of the lamp in the winter season and in the cold regions.

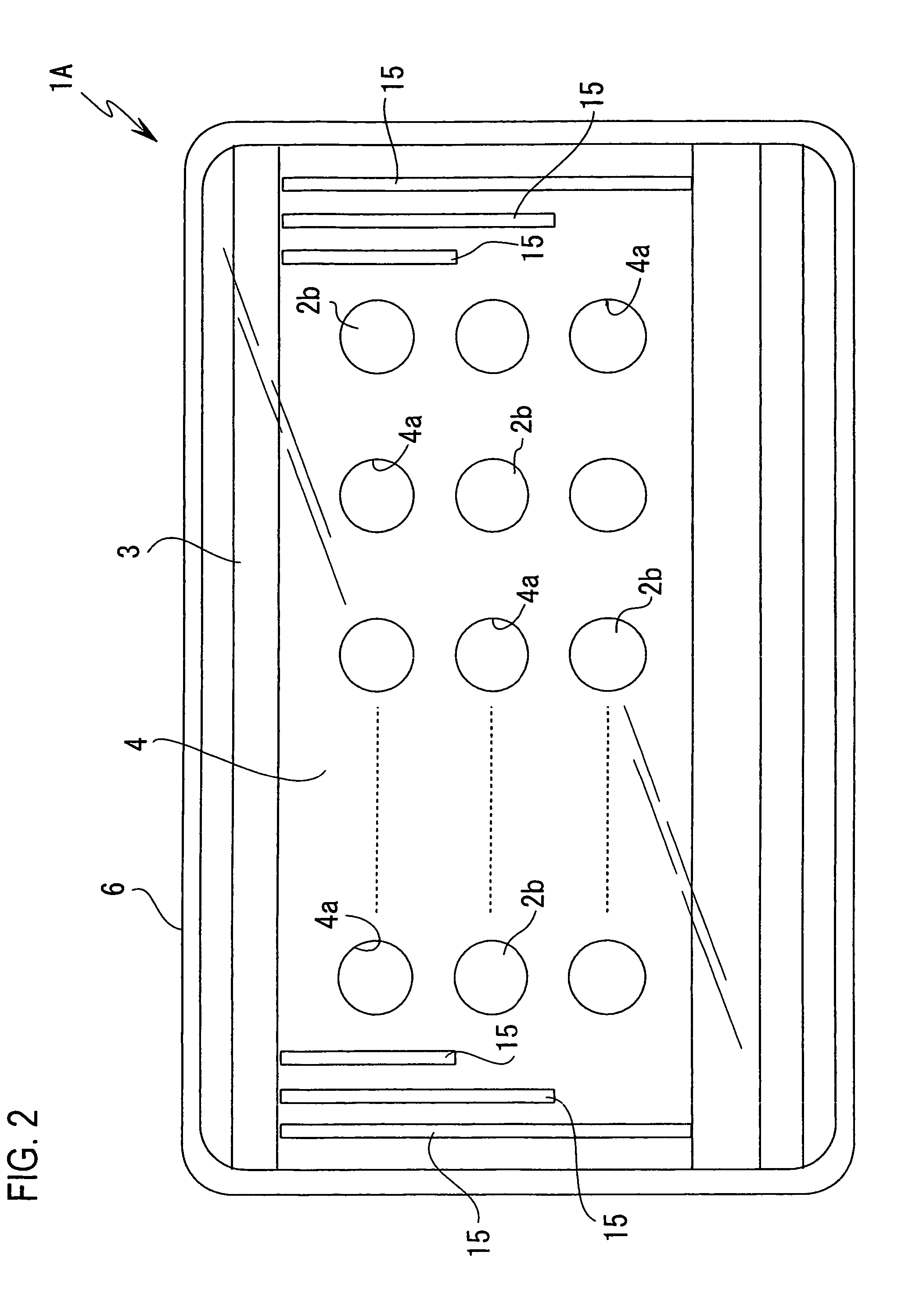

[0021]As seen from FIG. 1, the vehicular lamp 1 of the present invention includes a lamp unit 2, which uses a light-emitting diode 2a, and a cover member 4, which is positioned near the inside surface of the outer lens 3 installed in front of that lamp unit 2 (the direction in which light is radiated (left side in FIG. 1) is defined as the “front”).

[0022]In this lamp unit 2, light directly emitted from the light-emitting diode 2a passes, through a lamp unit lens 2b and goes through a translucent hole 4a of the cover member 4; and then the light is transmitted through the outer lens 3 and radiated forward. The structure of the lamp unit 2 is not limited to the on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com