Method for planning and/or configuring a project

a technology for planning and/or configuration and project, applied in the direction of programme control, electric controllers, total factory control, etc., can solve the problems of long response time, substantial performance problems, and easy errors in steps, so as to improve the planning and/or configuration of the project, and simplify the method of planning and/or configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

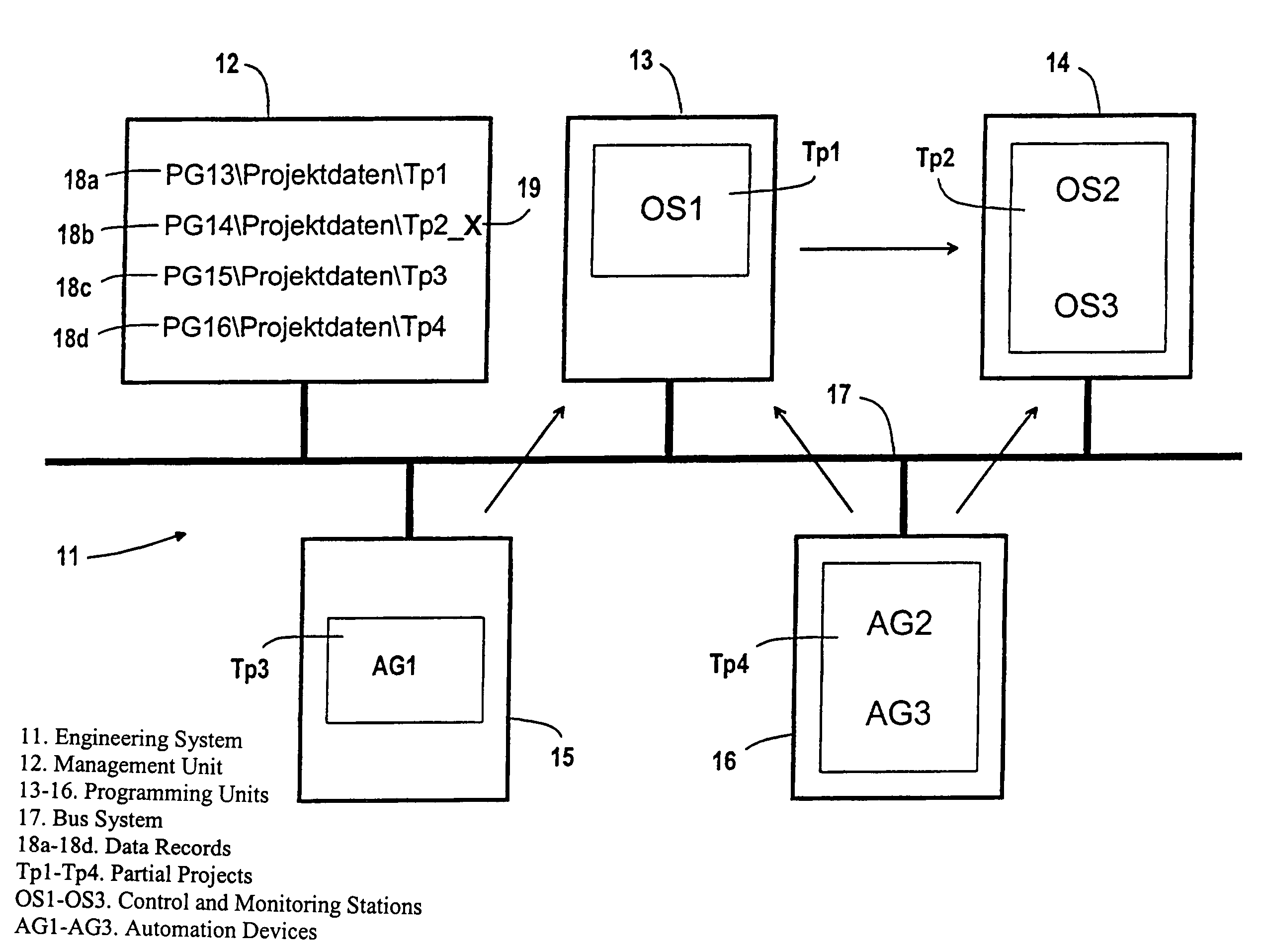

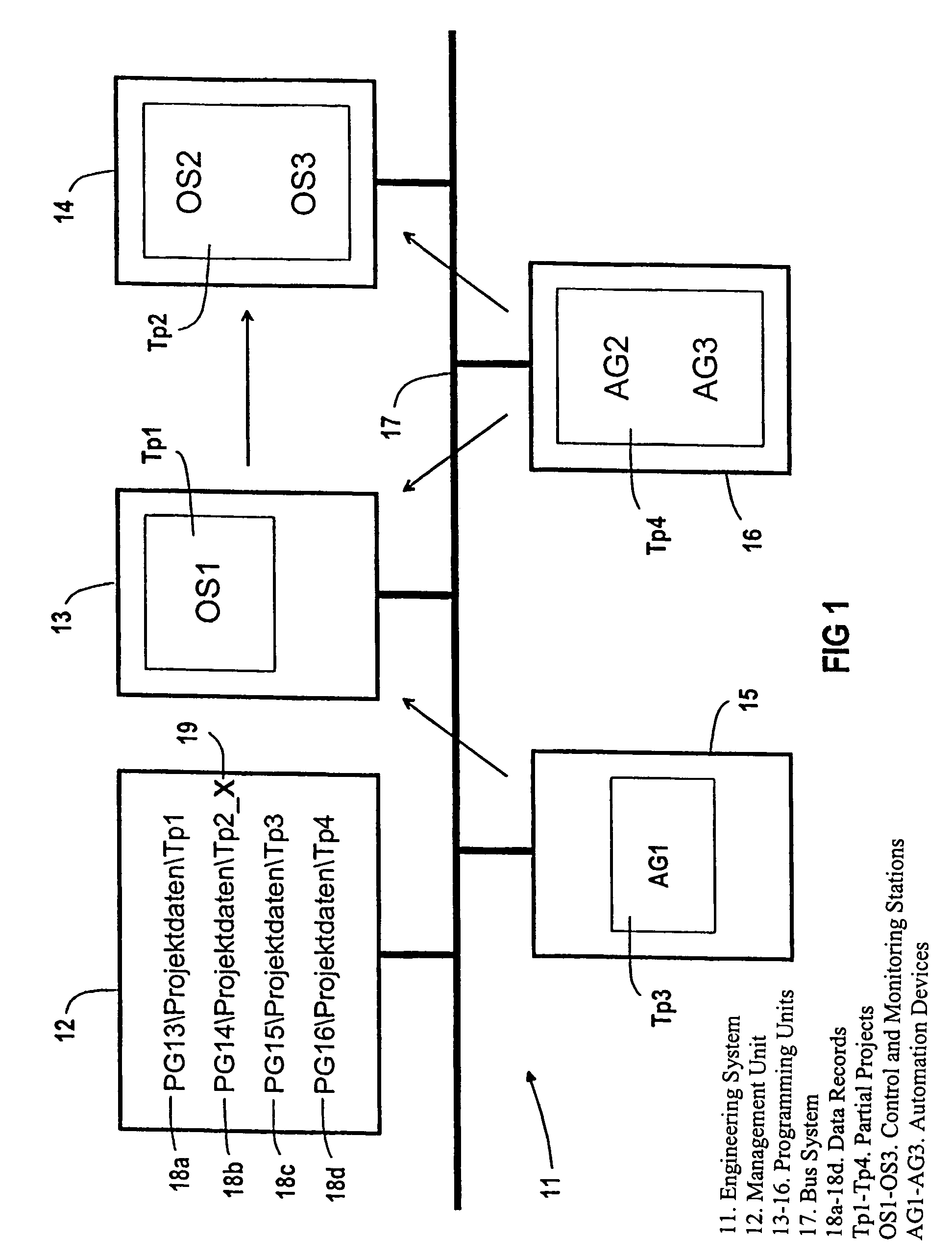

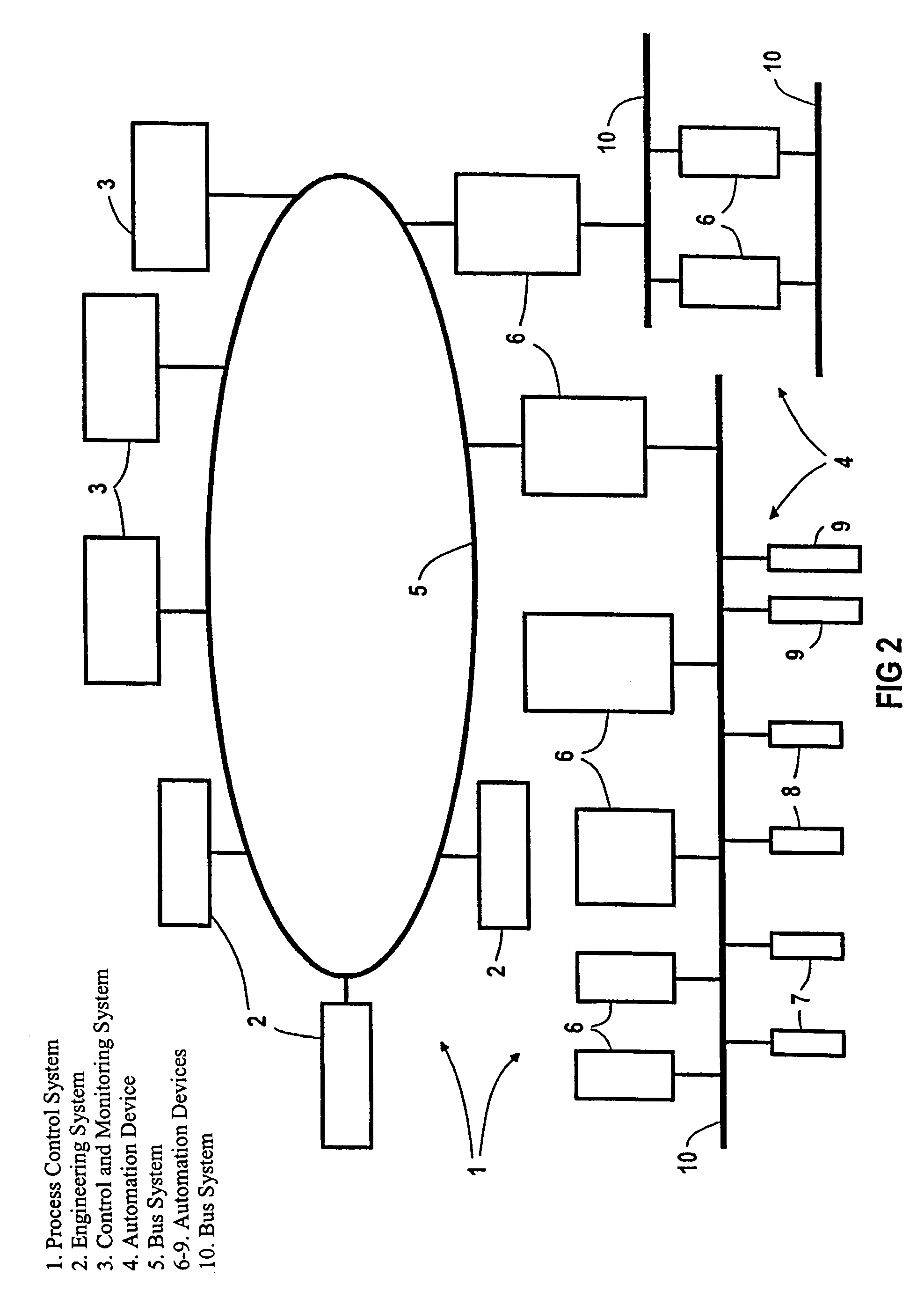

[0017]Reference is first made to FIG. 2, which shows a process control system 1. The process control system 1 has an engineering system 2, a control and monitoring system 3, and a planned and configured automation device 4. The engineering system 2 is provided for planning and / or configuring the automation device 4. The automation device 4, which is connected to the engineering system 2 and the control and monitoring system 3 by a bus system 5 and bus connections (not depicted), includes various automation devices 6, actuators 7, sensors 8 and other automation components 9 required to control a technical installation.

[0018]The automation devices 6, which are interconnected by the bus system 5 and / or other suitable bus systems 10, can have different configurations. For example, ordinary automation devices for solving small, medium-sized and larger automation tasks are provided within the automation device 4. As a non-limiting example, programmable micro-controllers can be used to sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com