Control system for internal combustion engine

a control system and internal combustion engine technology, applied in the direction of electric control, machines/engines, liquid fuel feeders, etc., can solve the problems of increasing the amount of gasoline injection and so as to suppress the delay in the flow of fuel, improve the response of torque during acceleration, and suppress the effect of the delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

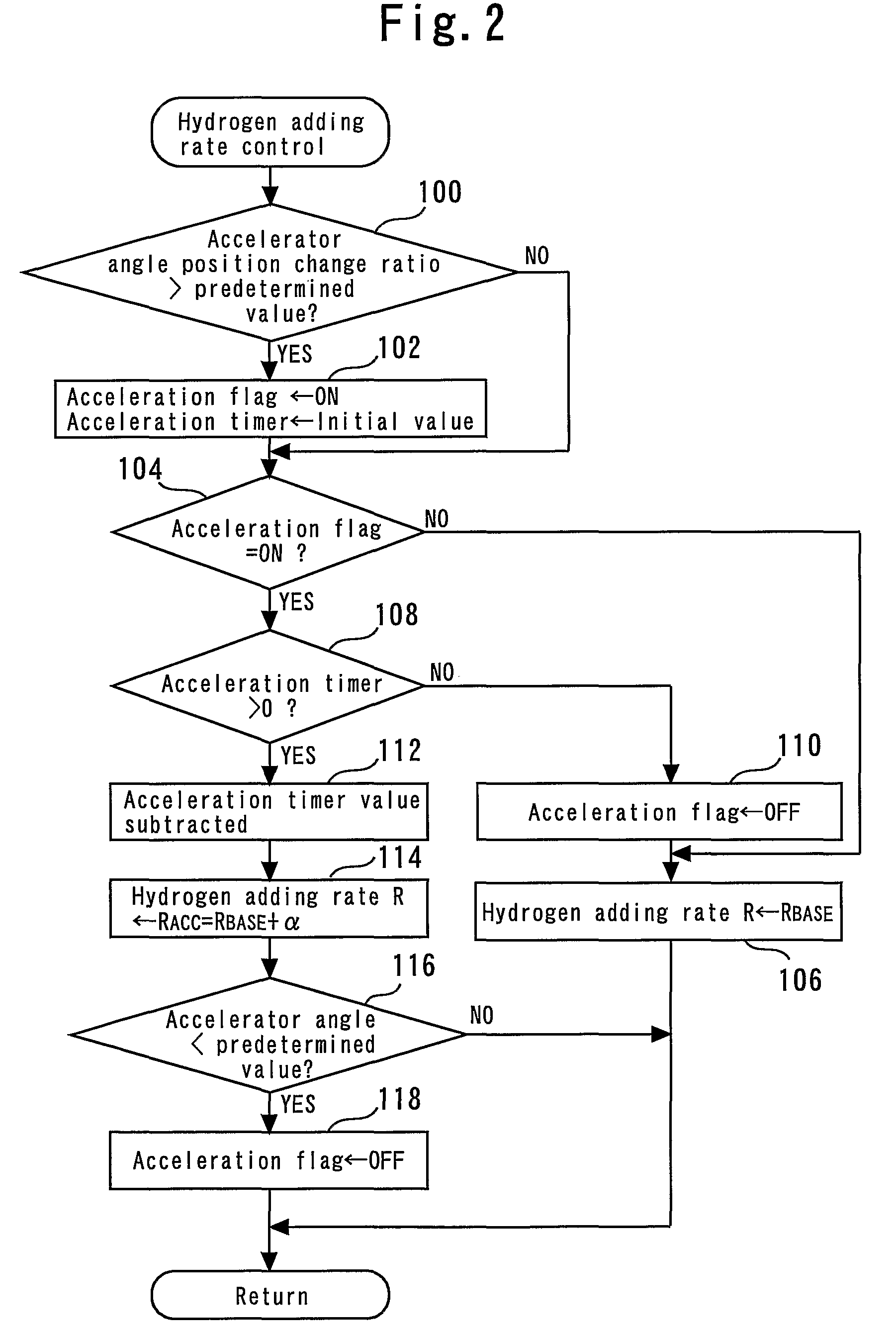

first embodiment

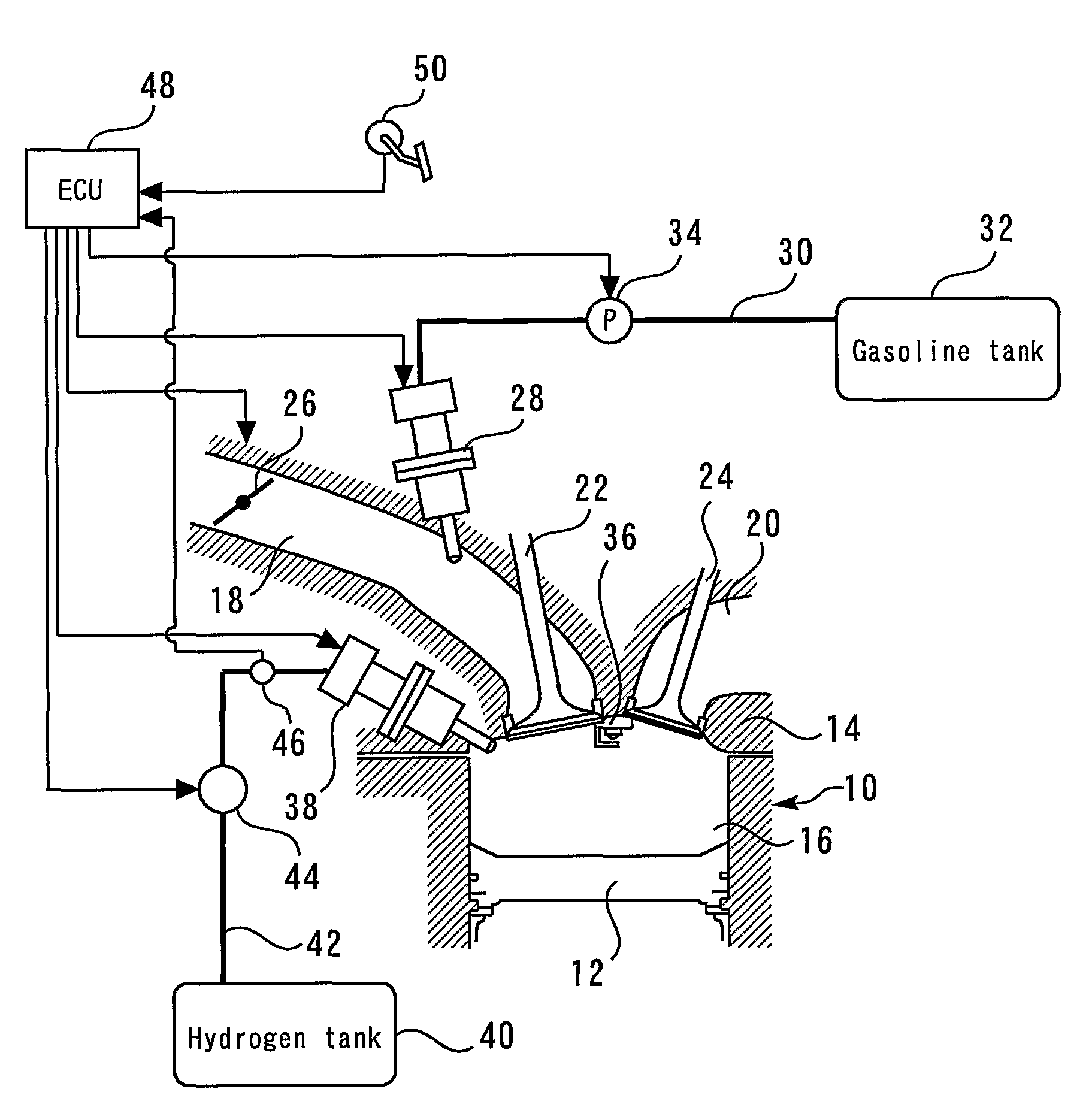

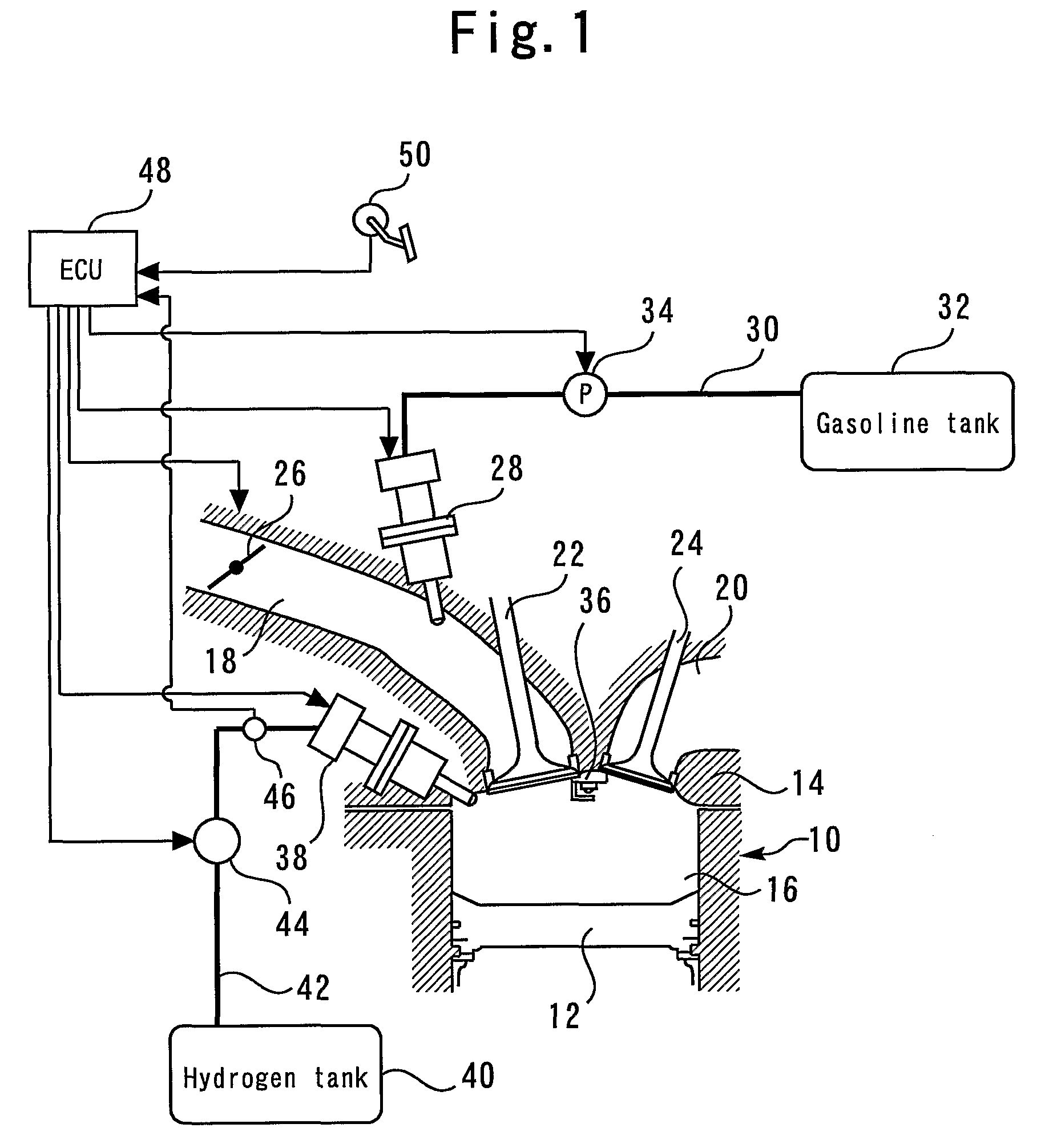

[0018]FIG. 1 is a diagram explaining a configuration of an internal combustion engine 10 in a first embodiment of the present invention. The internal combustion engine 10 has a piston 12 that reciprocates inside a cylinder of the engine. The internal combustion engine 10 also has a cylinder head 14. A combustion chamber 16 is formed between the piston 12 and the cylinder head 14. An air intake passageway 18 and an exhaust passageway 20 are communicated with the combustion chamber 16. An air intake valve 22 and an exhaust valve 24 are disposed in the air intake passageway 18 and the exhaust passageway 20, respectively. A throttle valve 26 is also provided in the air intake passageway 18. The throttle valve 26 is an electronically controlled throttle valve whose throttle angle position can be controlled independently of an accelerator angle position.

[0019]A gasoline injection valve 28 for injecting the gasoline that is a main fuel, into the air intake port, is provided in the air inta...

second embodiment

[0035]Next, a second embodiment of the present invention will be described referring to FIGS. 4A to 4F.

[0036]A system of the present embodiment is realized by making an ECU 48 execute a routine similar to that of FIG. 2, by use of the system configuration of the above described first embodiment. More specifically, processing in the routine similar to that of FIG. 2 is essentially the same as the processing routine shown in FIG. 2, except that a setting of an acceleration incremental value “β” of a hydrogen adding ratio differs from the setting of the acceleration incremental value “α” in the above described first embodiment. For this reason, description based on a flowchart will be omitted hereinafter and a description will be given of setting an acceleration mode hydrogen adding rate “RAcc” in the present second embodiment referring to FIGS. 4A to 4F.

[0037]FIGS. 4A to 4F are timing charts showing an example of the operation implemented by the system of the present embodiment. FIGS....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com