Medical devices having full or partial polymer coatings and their methods of manufacture

a technology of polymer coating and medical devices, applied in the field of biomedical devices, can solve problems such as obtaining adequate adhesion of the polymer coating to the instrument substrate, and achieve the effect of improving the adhesion of the polymer coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]The invention is described herebelow with reference to certain examples or embodiments as shown in the accompanying drawings. These examples or embodiments are not limiting, but rather are merely exemplary of some of the ways in which the present invention may be reduced to practice.

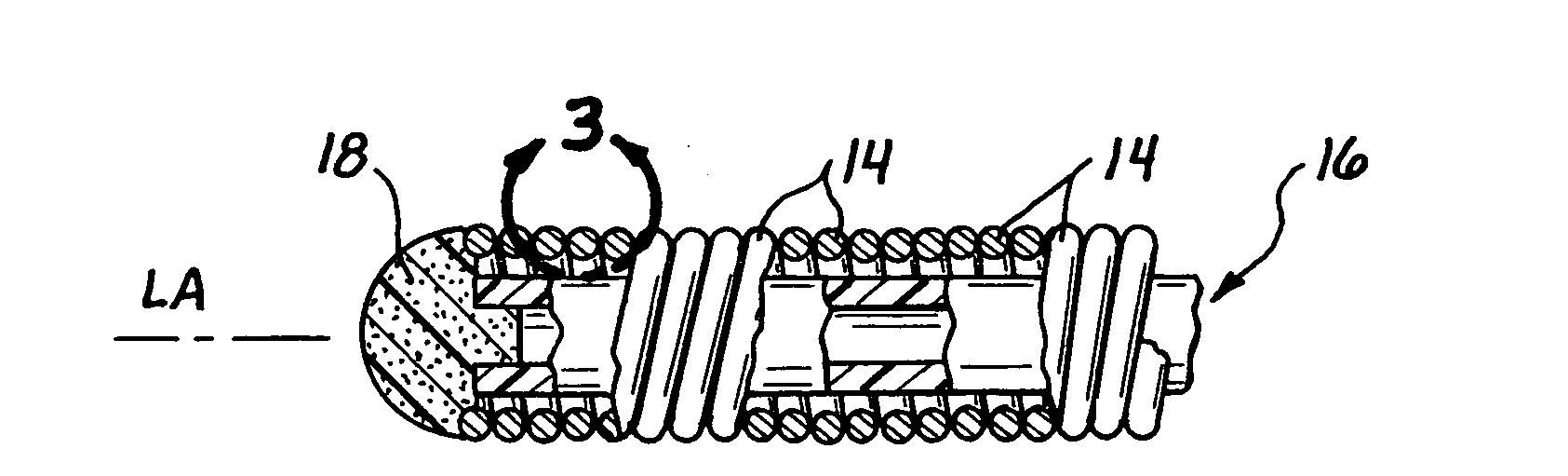

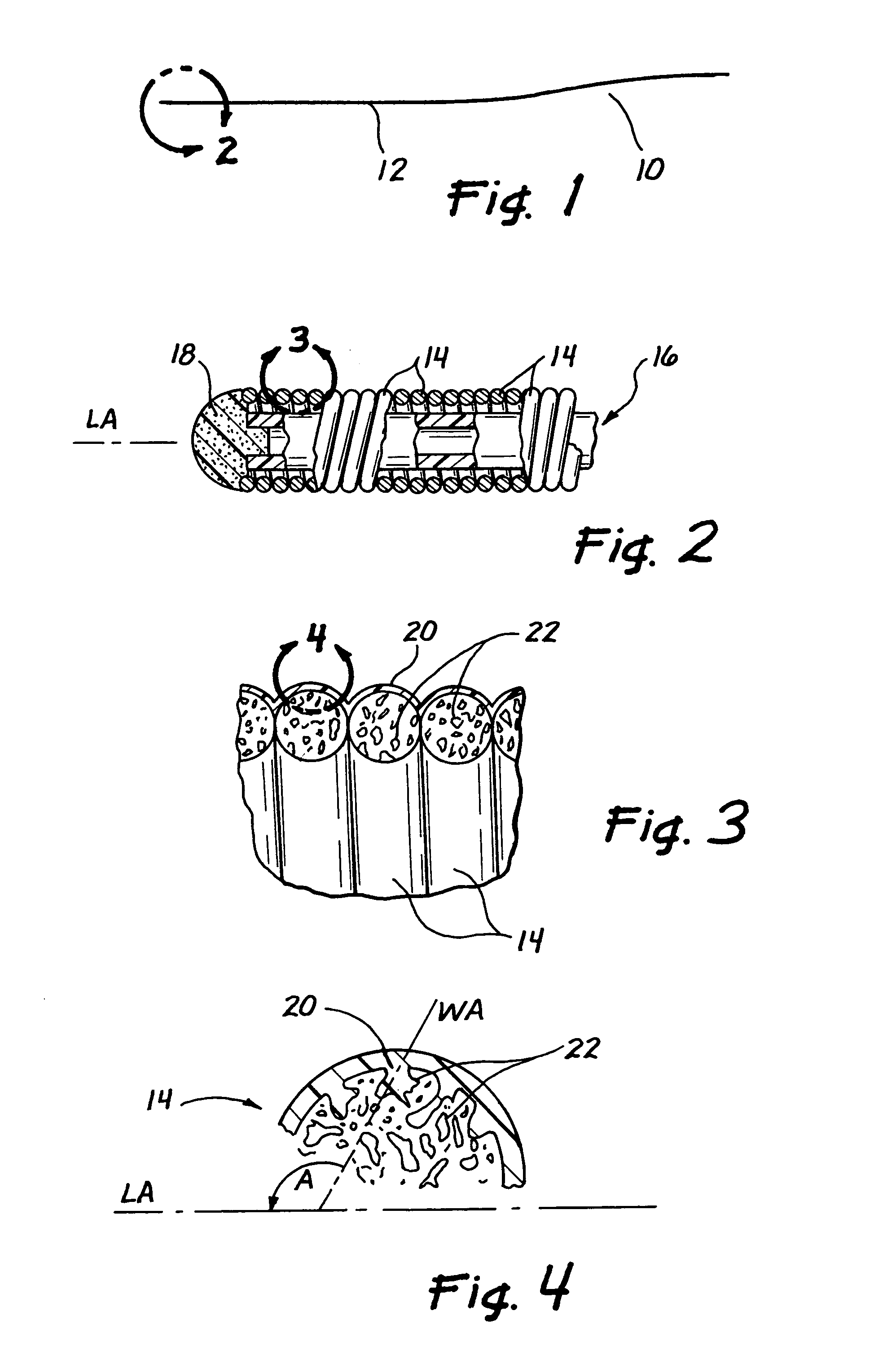

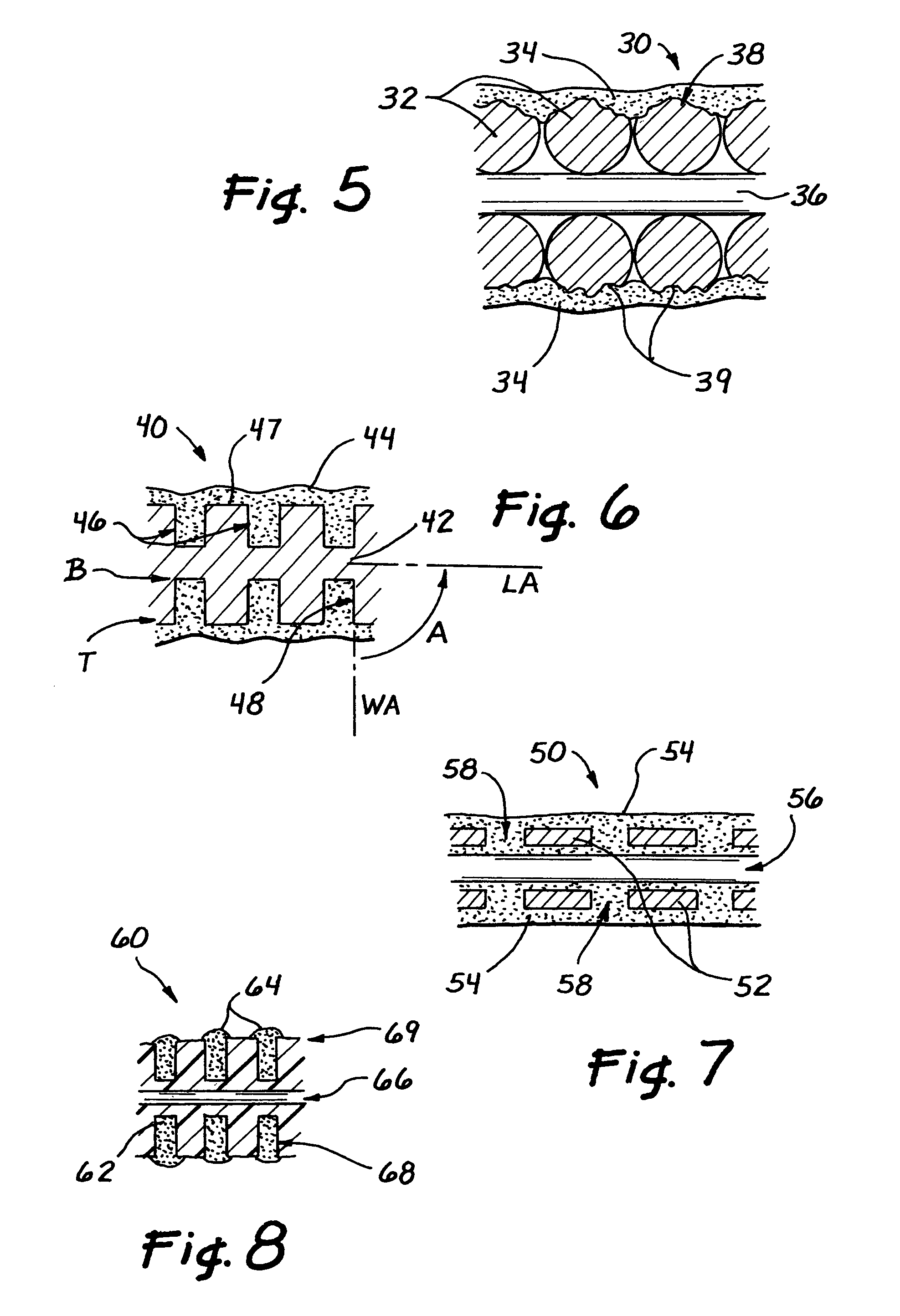

[0024]FIGS. 1-4 show an example of a guidewire 10 that bears a polymer coating according to this invention. As shown, the guidewire 10 comprises an elongate, flexible body 12 having a blunt distal tip member 18 positioned at its distal end. The guidewire body 12 comprises a continuous, tightly wound, helical coil formed of wire 14. A solid or tubular core member 16 may optionally be disposed within the helically wound wire 14. Pores 22 are formed in at least the outer surface of the helically coiled wire 14. A polymer coating 20 is disposed on the outer surface of the guidewire body 12, as shown. A portion of such polymer coating extends into some of the pores 22 at the surface of the wire 14, as c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com