Catheter guide wire especially for percutaneous transluminal coronary angioplasty

a technology of catheter guide wires and percutaneous transluminal coronary angioplasty, which is applied in the direction of guide wires, sensors, medical science, etc., can solve the problems of increased susceptibility of the wire shaft to notch breakage, and injury to the vessel wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

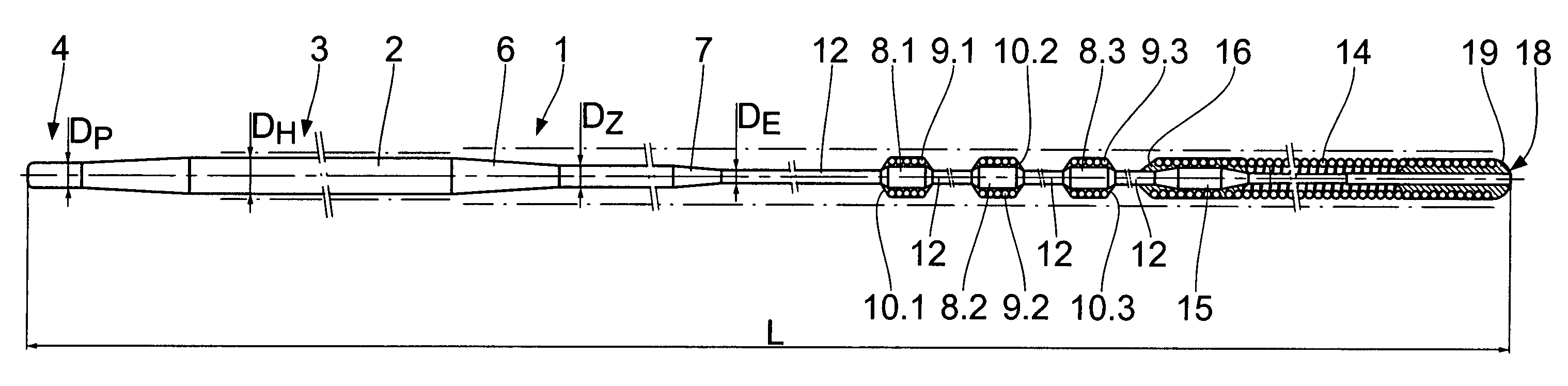

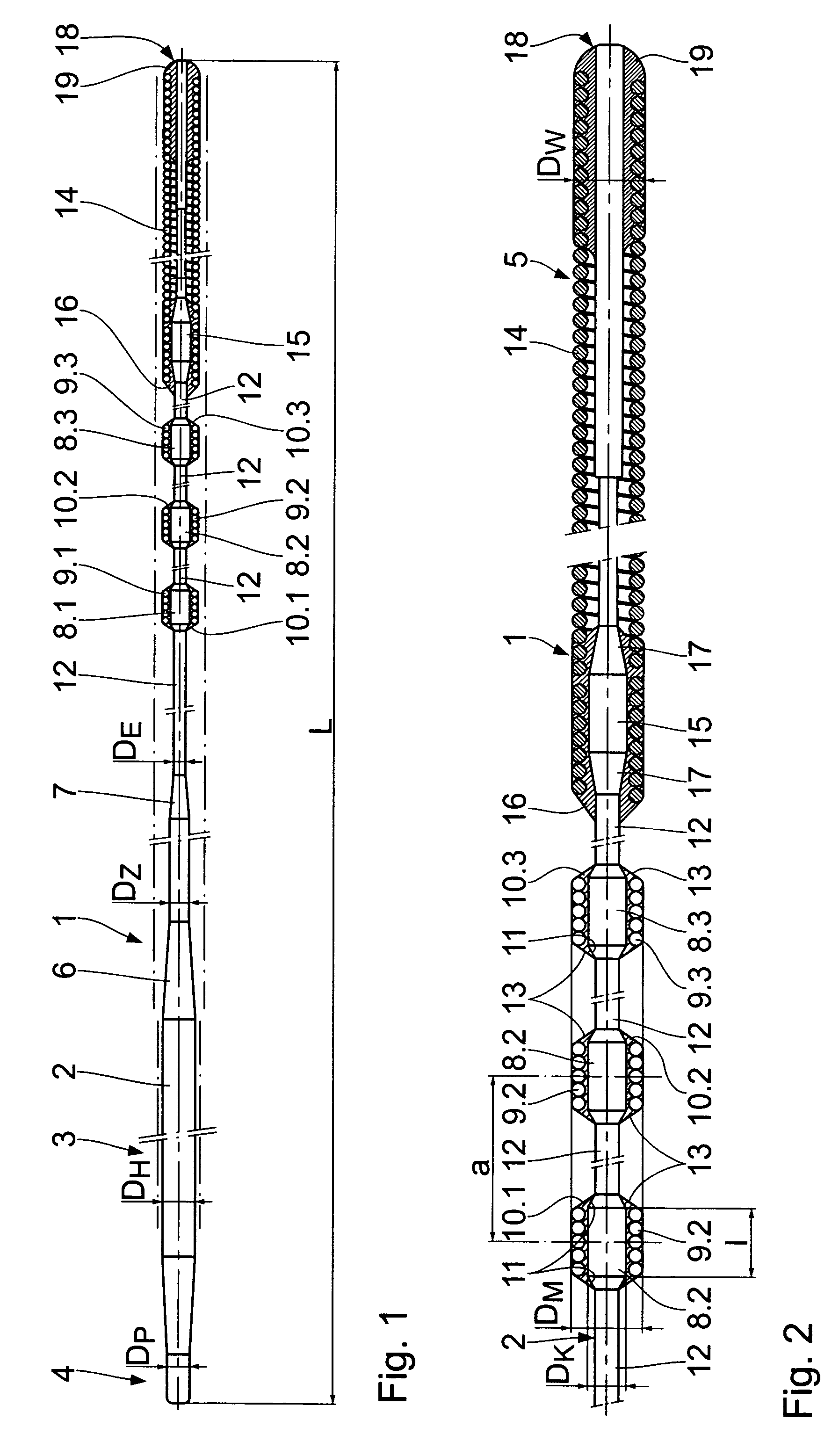

[0013]As is apparent from FIG. 1, the guide wire, which has been marked in its entirety with 1, incorporates an elongated wire shaft 2 of medical-grade stainless steel. Shaft sections of varying diameters are provided over its total length L of, for example, 1750 mm. The wire shaft 2 thus has at its proximal end 3, for example, a conically narrowing end section, whose outside diameter DP of, for example 0.223 mm, is significantly smaller than the main diameter DH of the wire shaft 2 of 0.36 mm. The conically narrowing proximal end 3 of the wire shaft 2 serves to attach a wire extension.

[0014]In the distal end zone, whose length may be altogether approximately 300 mm, which is located adjacent to the distal end 5 of the guide wire 5, the wire shaft 2 is reduced in its thickness from its main diameter DH over conical ramps 6, 7 to an intermediate diameter DZ of approximately 0.2 mm and to a final diameter DE of approximately 0.12 mm. In the process, however, core sections 8.1, 8.2, 8....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com