Thermal energy module

a technology of thermal energy modules and thermal energy storage, which is applied in the field of cold and hot thermal energy storage systems, can solve the problems of high energy consumption, high cost of gas turbines, and high cost of building, installation and operation of turbines, and achieves the effects of high energy efficiency, dissipation of energy, and high comfor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]The present invention is a means of storage for cold water (or similar energy transfer medium), ice, or hot water which may be generated by solar heaters wherein the means of storage allows for the ability to control demand and achieves a high level of energy efficiency by retaining extracted heat energy and reusing it for heating or generating hot water.

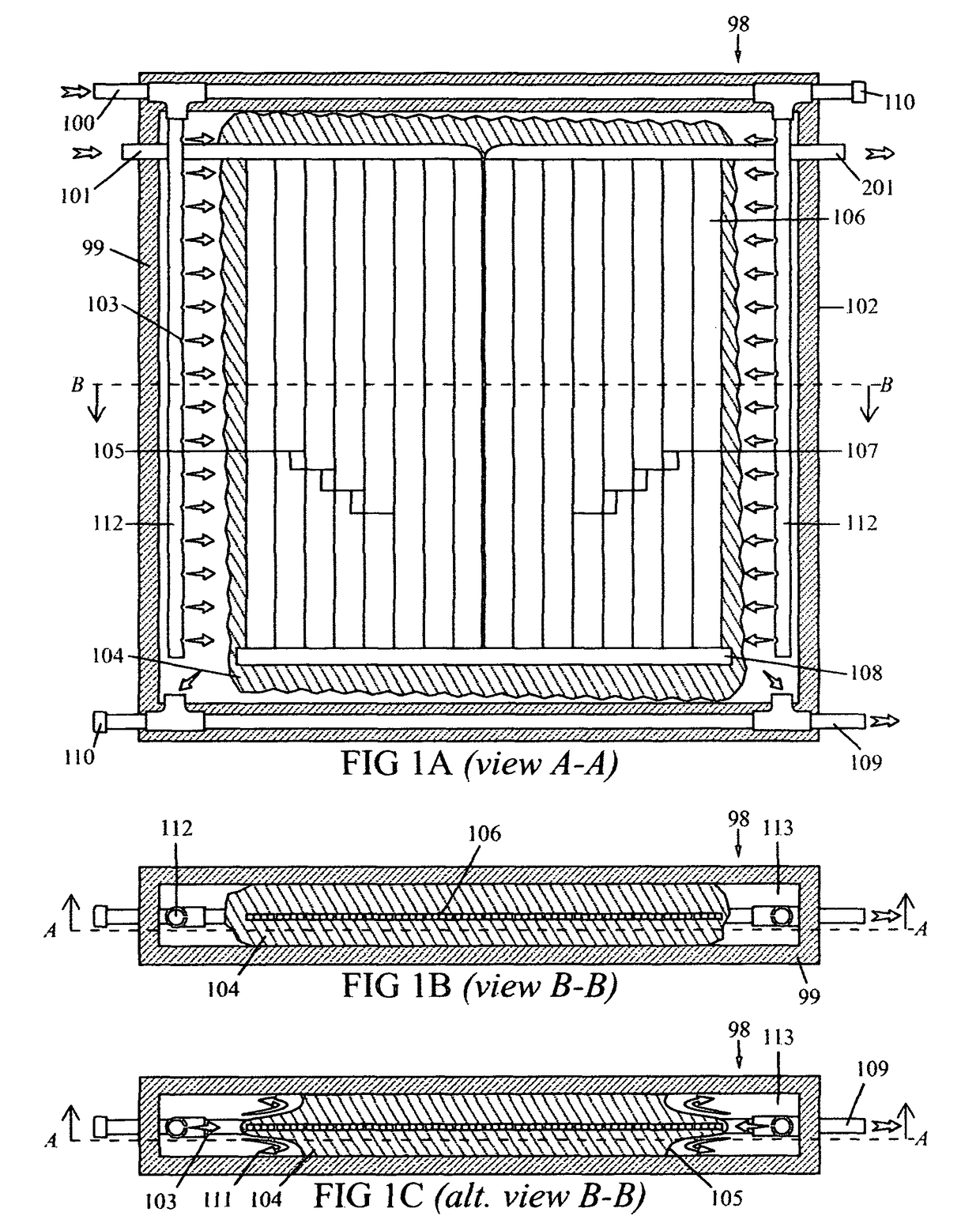

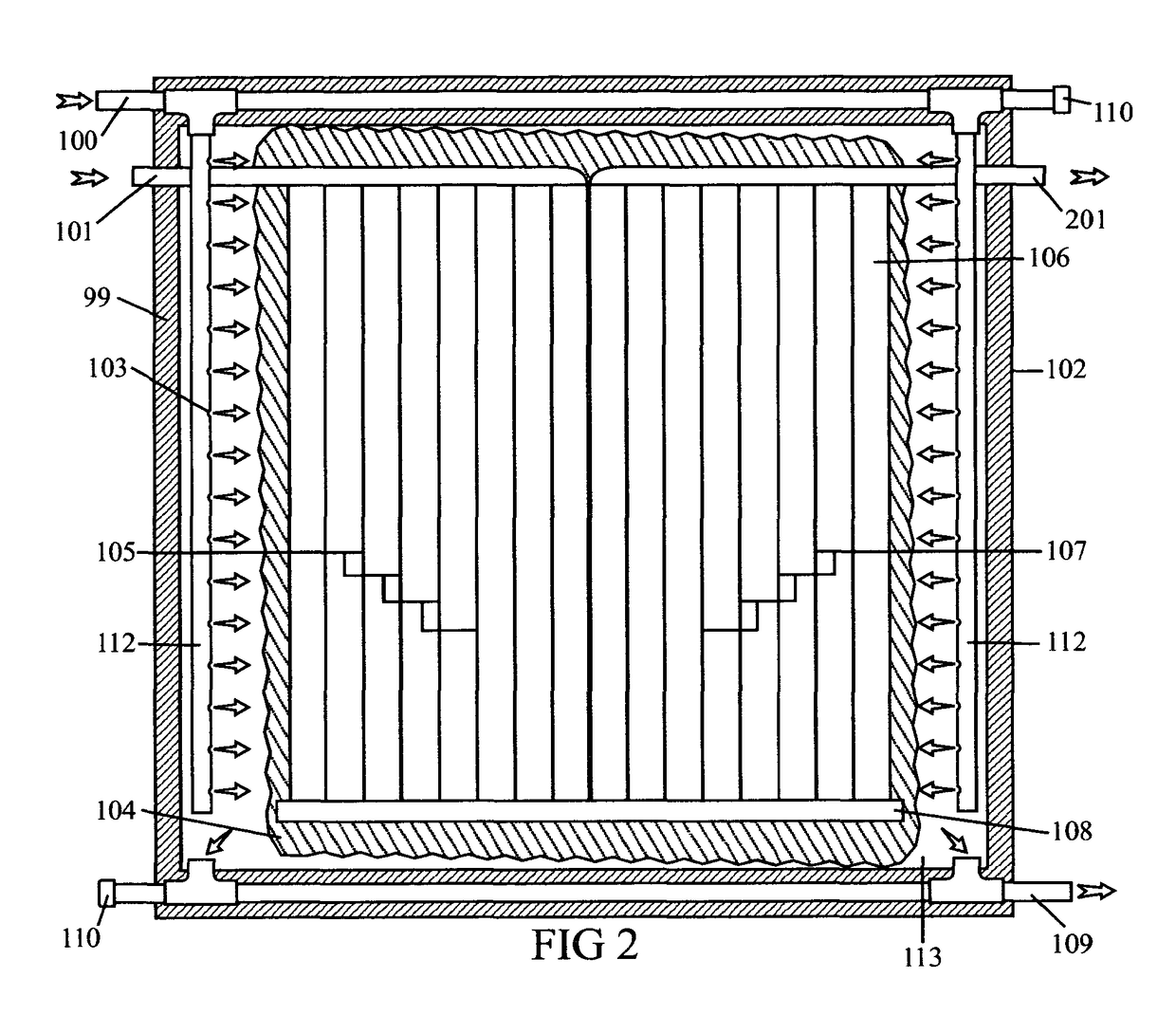

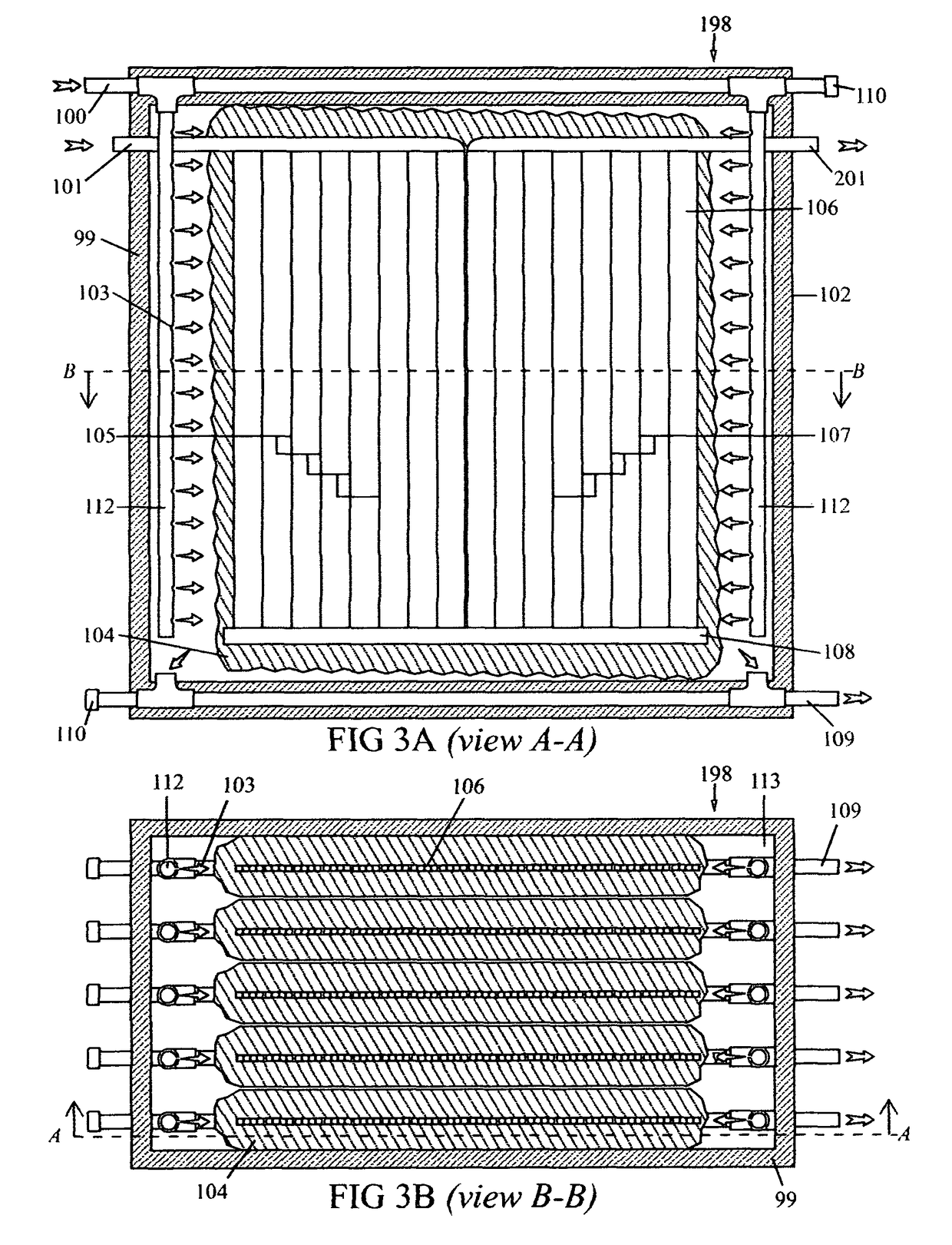

[0025]The present invention is a Thermal Energy Module comprising a tank and a flat heat exchanger. The heat exchanger is comprised of an intake manifold, a pass-through manifold, and an outlet manifold connected via micro-channel, pipe-in-plate panel, or similar thermal energy transfer structures which allow refrigerant liquid and vapor to move from the inlet manifold though a first energy transfer structure to the pass-through manifold and then through a second energy transfer structure to the outlet manifold. The heat exchanger is located within a tank and its size relative to the tank is designed to prevent ice from formin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com