Energy management apparatus and method

a technology of energy management and equipment, applied in the field of energy management techniques, can solve the problems of difficult to achieve both the target operating condition and the saving of energy consumption, and cannot be said that the above-mentioned means is a realistic solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]A description will now be given, with reference to the drawings, of an energy management apparatus according to an embodiment of the present invention.

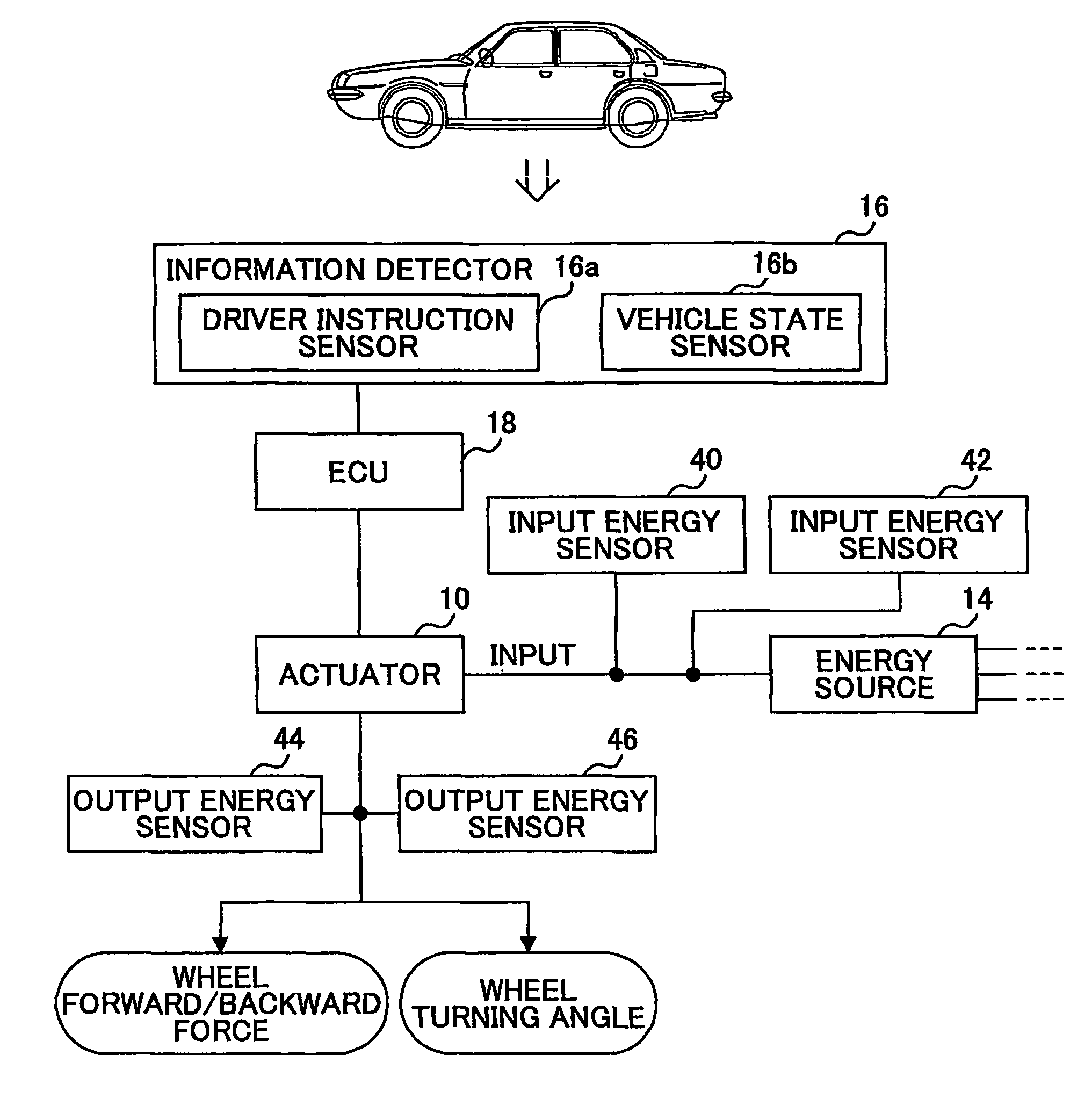

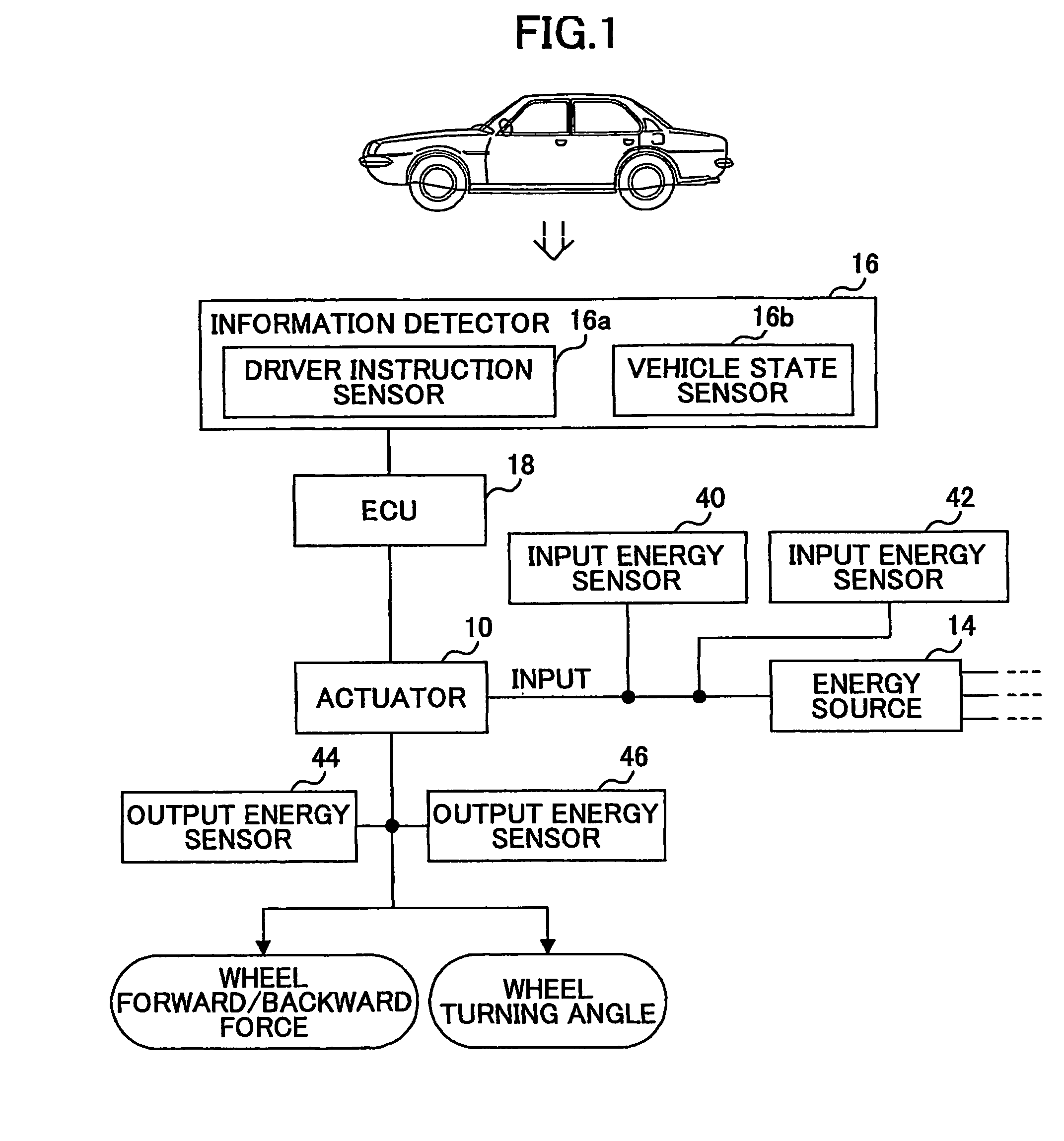

[0047]FIG. 1 is a block diagram of a drive control system serving as an energy management apparatus according to the present invention. The drive control system shown in FIG. 1 is mounted in an automobile (hereinafter may be referred as “vehicle”) as a movable body, which is an example of machines. The automobile is equipped with a plurality of actuators 10 (only one actuator 10 is shown in FIG. 1 for the sake of simplification). The automobile is further equipped with an energy source 14 that supplies energy to each of the actuators 10. As the energy source 14, a fuel, a battery cell, a fuel cell, or an engine (internal combustion engine) may be used. The plurality of actuators 10 provided in the automobile may include the following actuators.

[0048](1) An engine which generates a mechanical energy by combusting a fuel.

[0049](2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com