Watertight hatch

a hatch and watertight technology, applied in the field of hatches, can solve the problems of failure of watertight seal, unsatisfactory options, and inability to achieve watertight seals, and achieve the effect of accurately sealing the hatch and effectively opening and closing the hatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

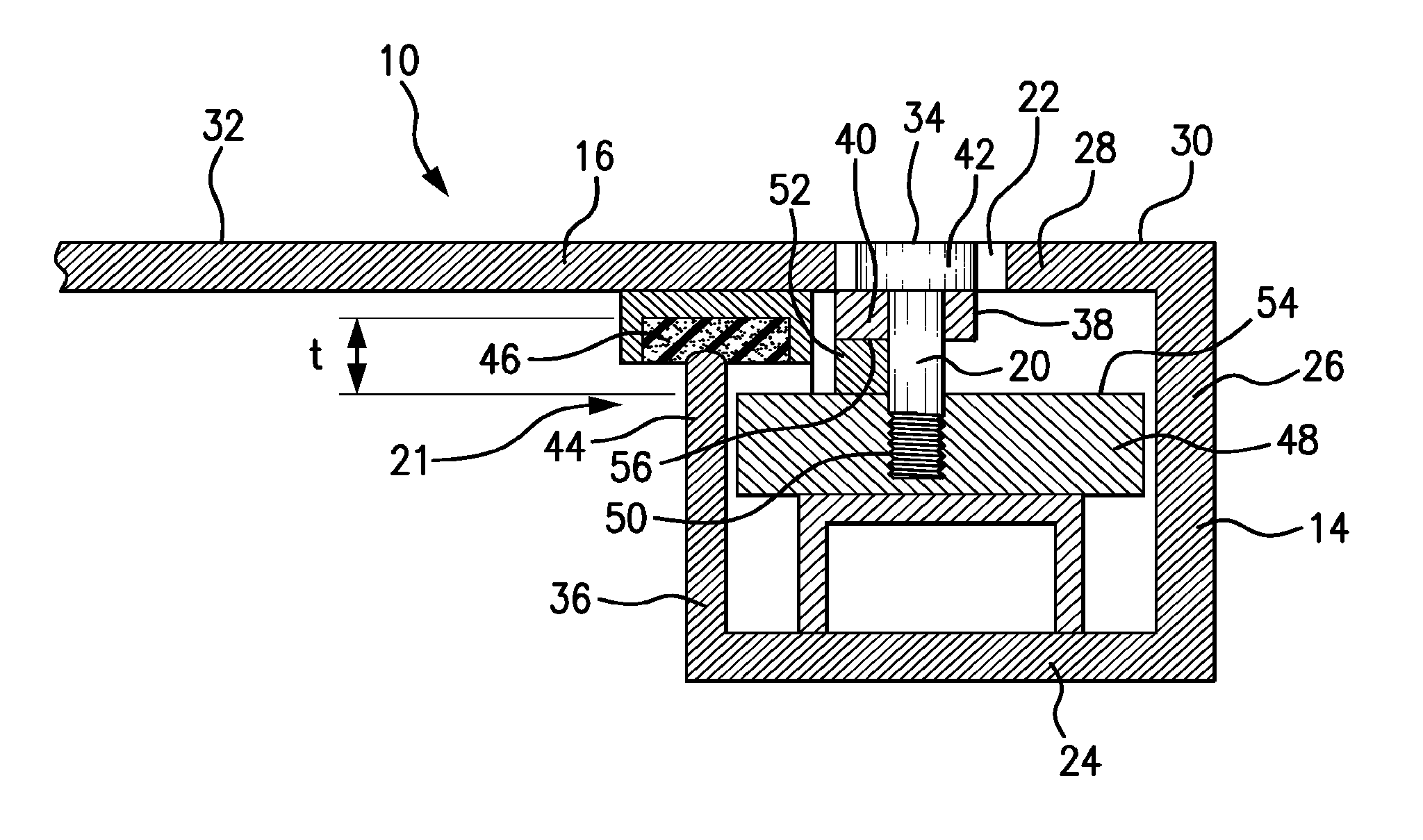

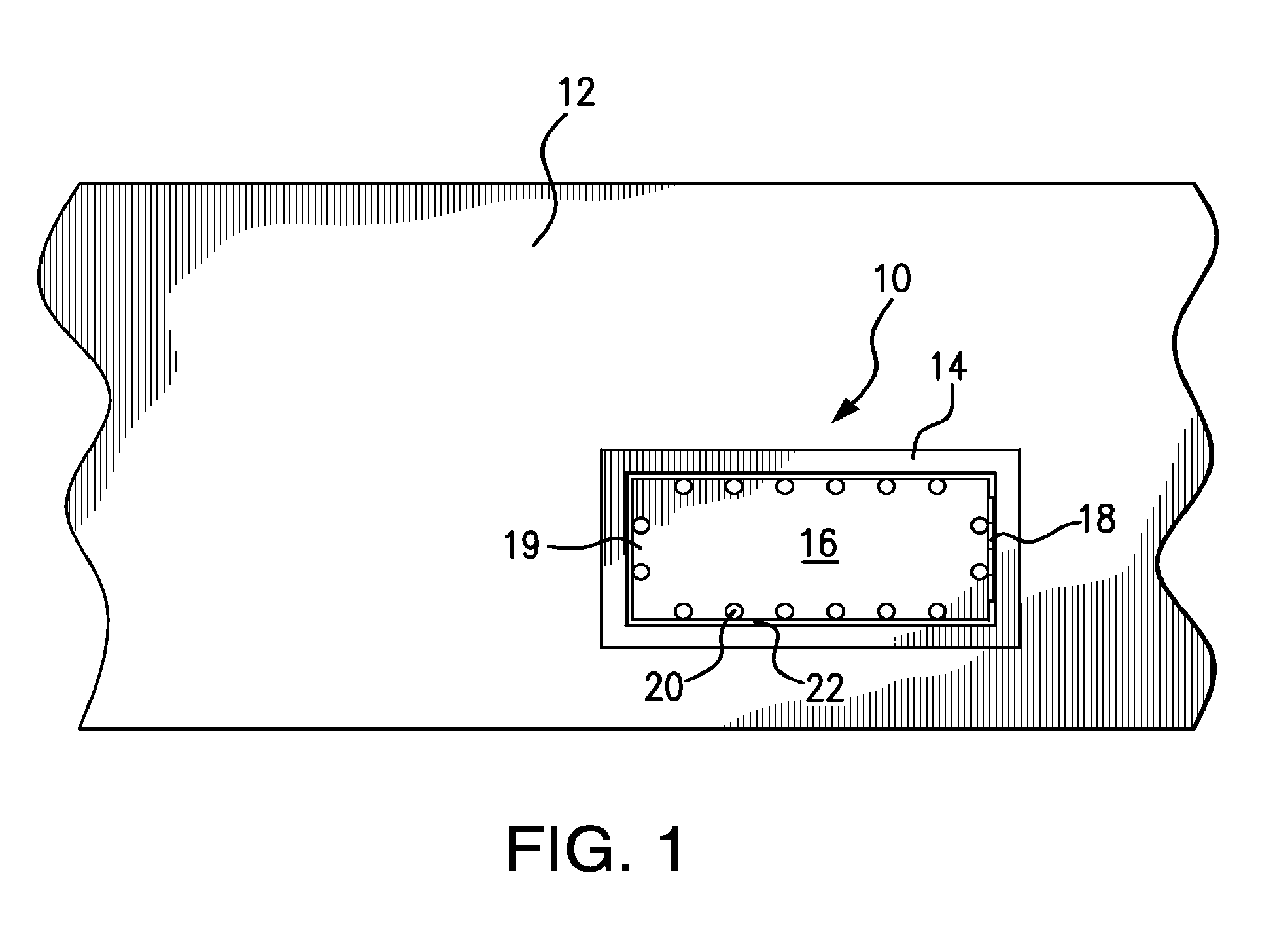

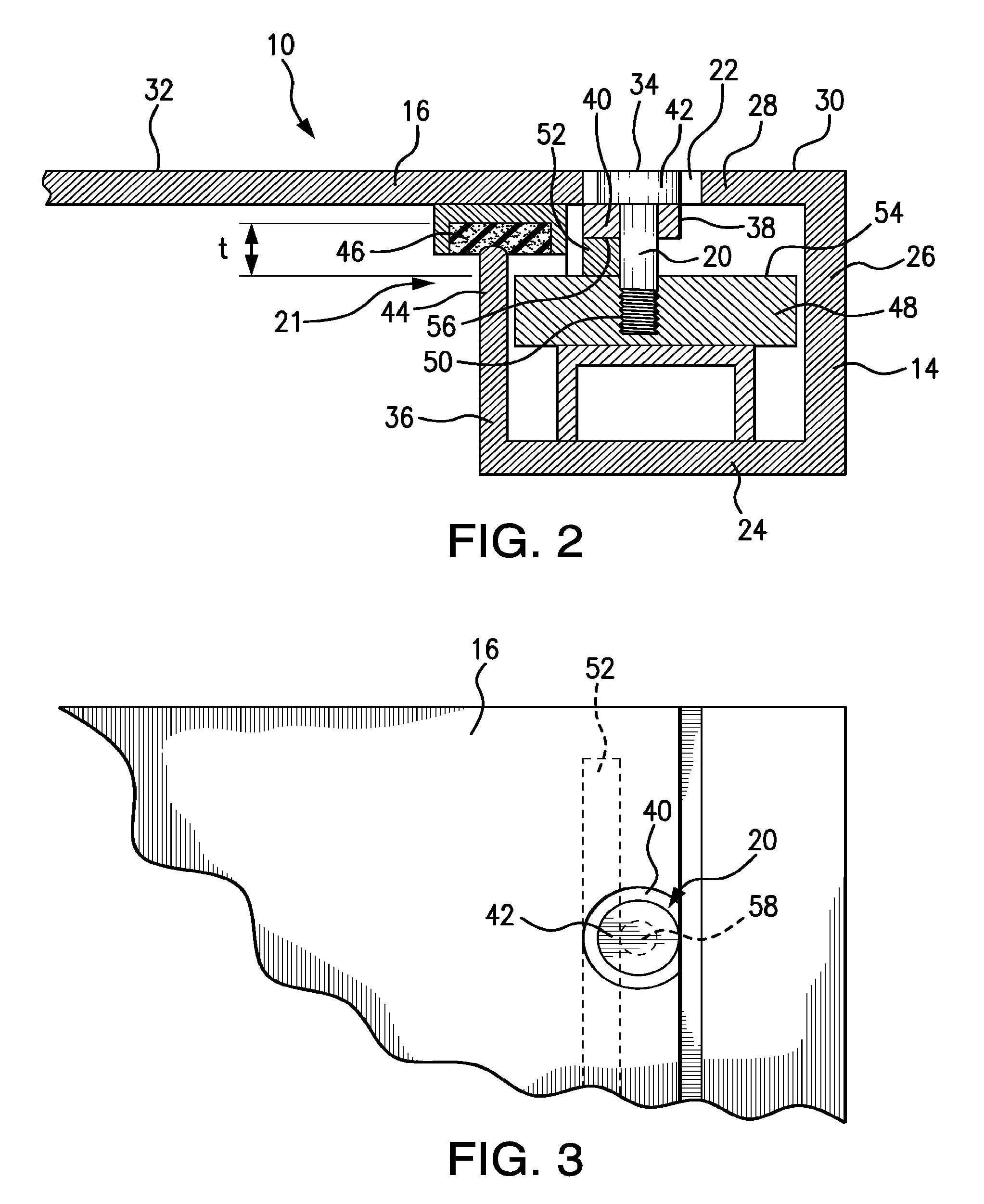

[0019]FIG. 1 is a top view of a hatch 10 having an upper surface that is flush with a surface 12, such as a sidewalk. The same hatch 10 may be installed flush with other surfaces, such as a roadway, town square, subway platform, or any other relatively flat surface used for pedestrian or vehicle transit. Typically the hatch 10 provides access to subsurface utilities such as power or signal lines. The hatch is formed from a suitable material such as aluminum, stainless steel or steel and may be coated to provide weatherproofing, by preventing damage from heat, sun, water, ice melting chemicals, and the like. The hatch 10 has a channel frame 14, typically formed from aluminum, circumscribing a cover plate 16. The cover plate 16 is attached to a hinge 18 at one end allowing it to swing open from the other end 19. To hold the hatch in place and to compress the gasket, a plurality of fasteners 20 are located around the perimeter of the cover plate 16. To enable easy opening and closing o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive force | aaaaa | aaaaa |

| perimeter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com