Component-incorporated wiring substrate and method of manufacturing the same

a technology of component-incorporated wiring and wiring substrate, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, and semiconductor/solid-state device details. it can solve the problems of failure to ensure sufficient connection reliability between the built-in component and the via conductor, increase in dc resistance associated, and reduce the dc resistance associated with the connection between the first via conductor and the terminal electrode. it achieves a wide connection, and reduces the dc resistance resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]A preferred embodiment of the present invention will next be described with reference to the drawings. However, the embodiment to be described below is a mere example of an application of the technical concept of the present invention. The contents of the embodiment should not be construed as limiting the invention.

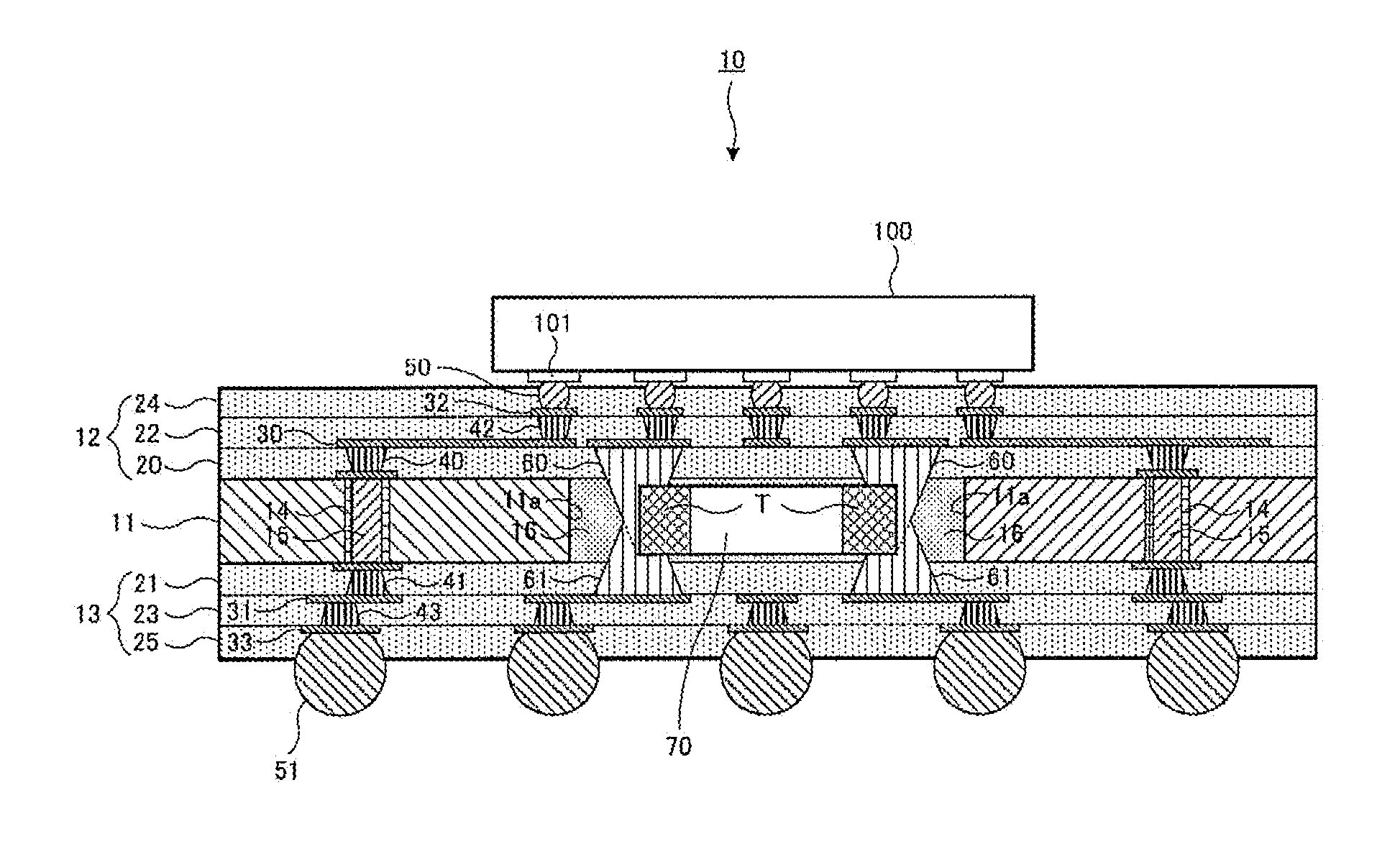

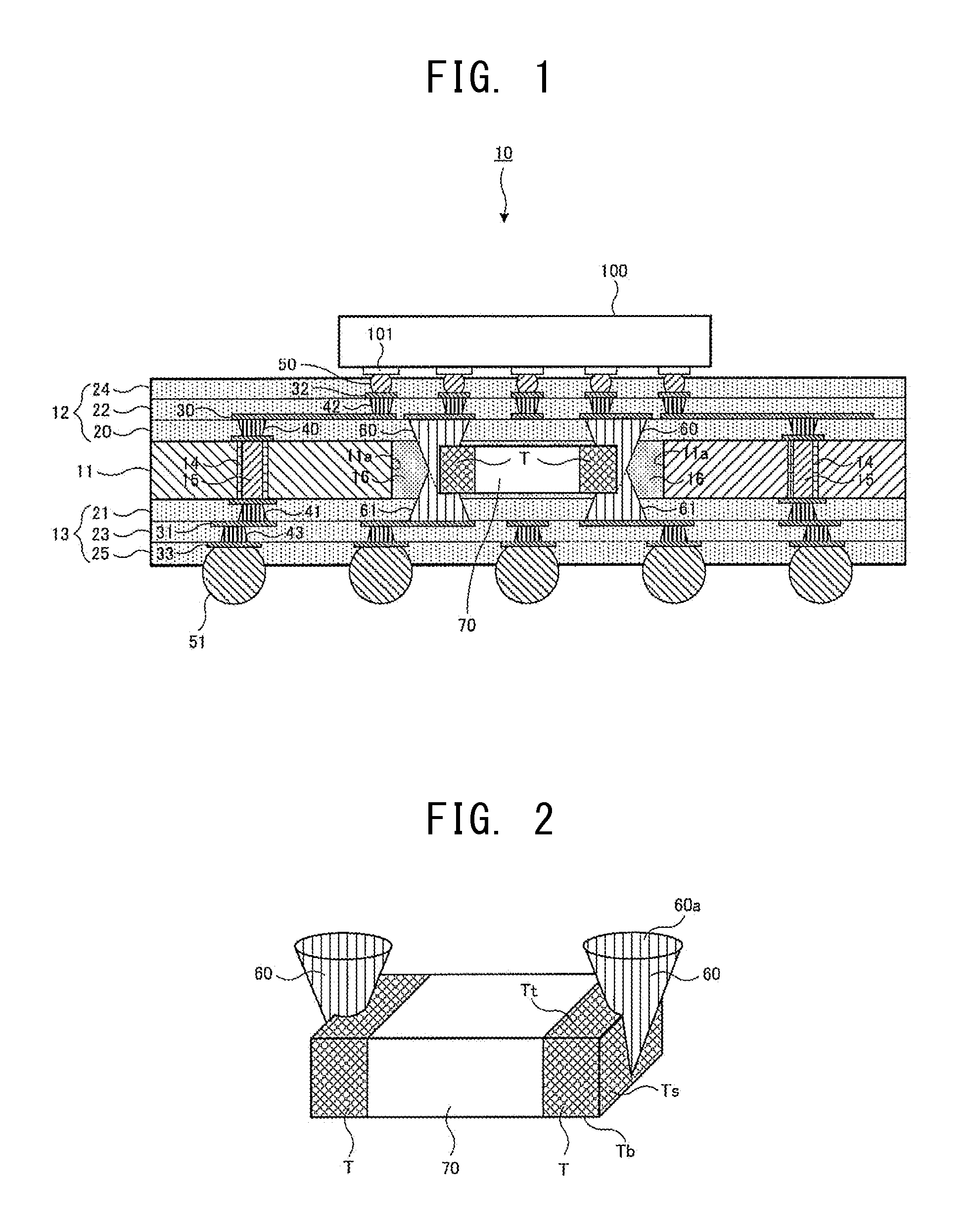

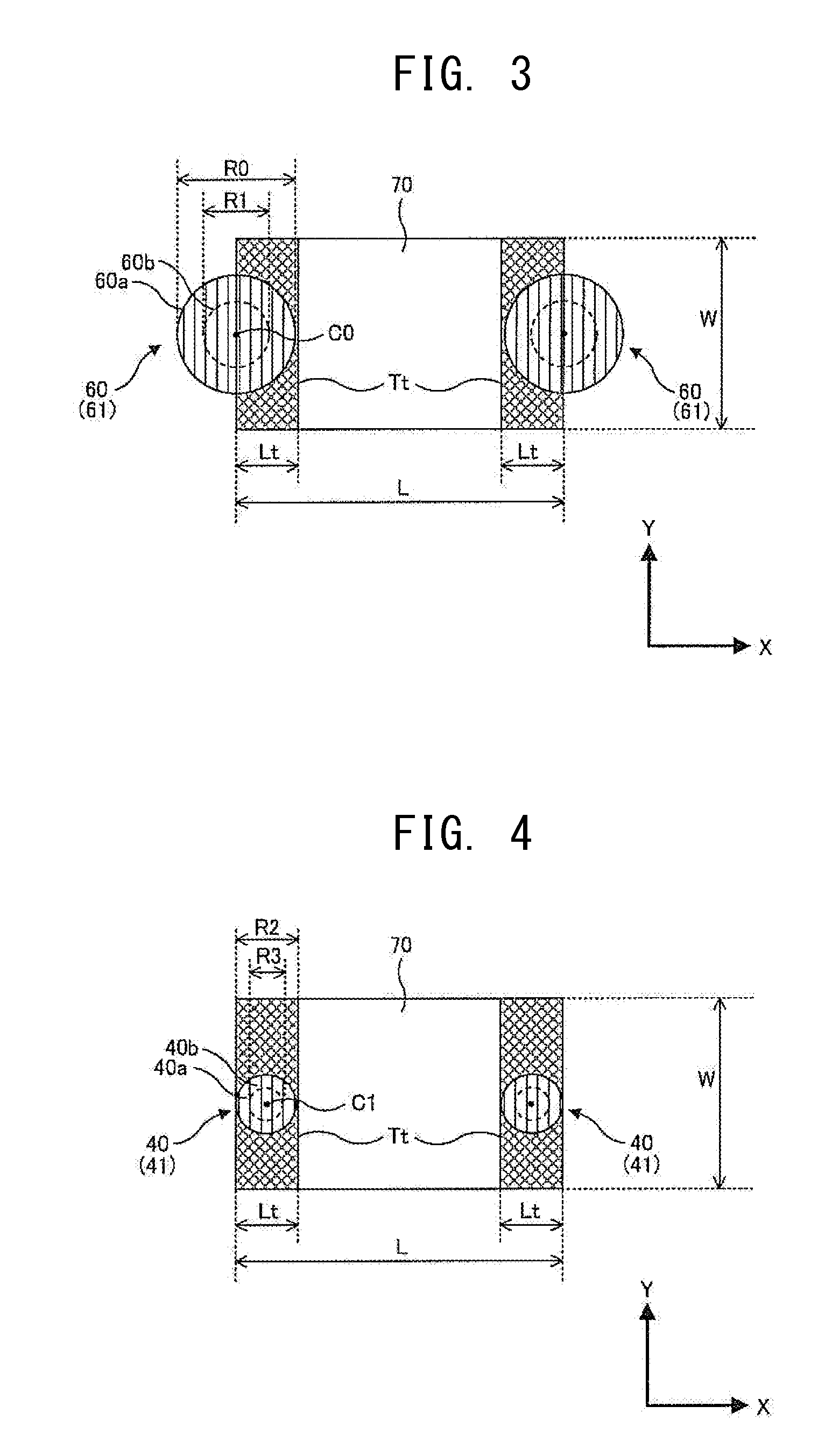

[0033]First, the structure of a component-incorporated wiring substrate according to an embodiment of the present invention will be described. FIG. 1 is a schematic sectional view showing the structure of a wiring substrate 10 having a built-in component (hereinafter referred to as “the wiring substrate 10”) of the present embodiment. As shown in FIG. 1, the wiring substrate 10 of the present embodiment includes a core substrate 11 formed from, for example, an epoxy resin which contains glass fiber, a build-up layer 12 on a side toward the upper surface of the core substrate 11, and a build-up layer 13 on a side toward the lower surface of the core substrate 11. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| via diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com