Inflatable structure with braided layer

a technology of balloons and braided layers, which is applied in the field of composite structures of medical balloons, can solve problems such as delicate materials, and achieve the effect of consistent, predictable, or tighter balloon folding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060]The various embodiments will be described in detail with reference to the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

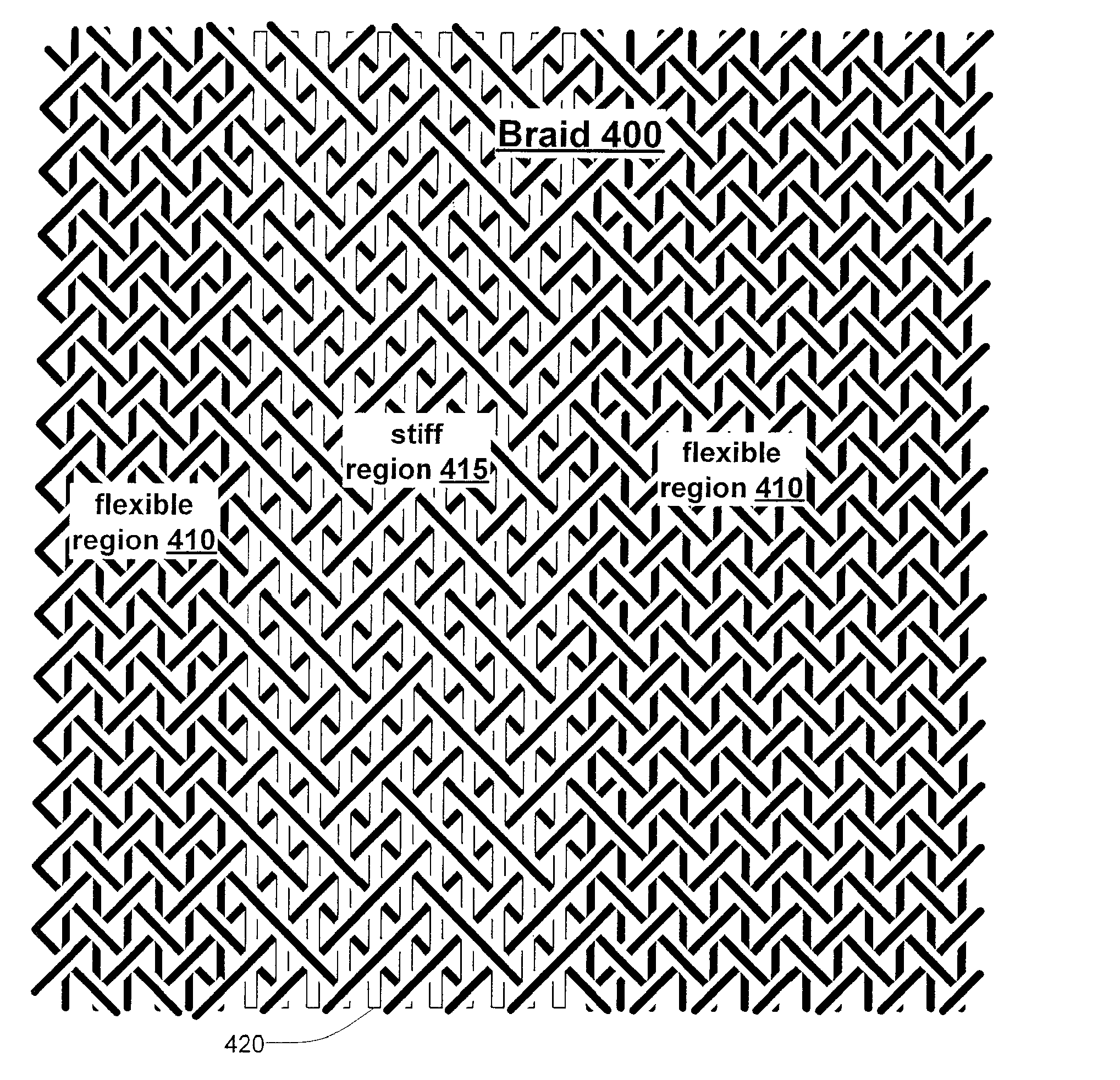

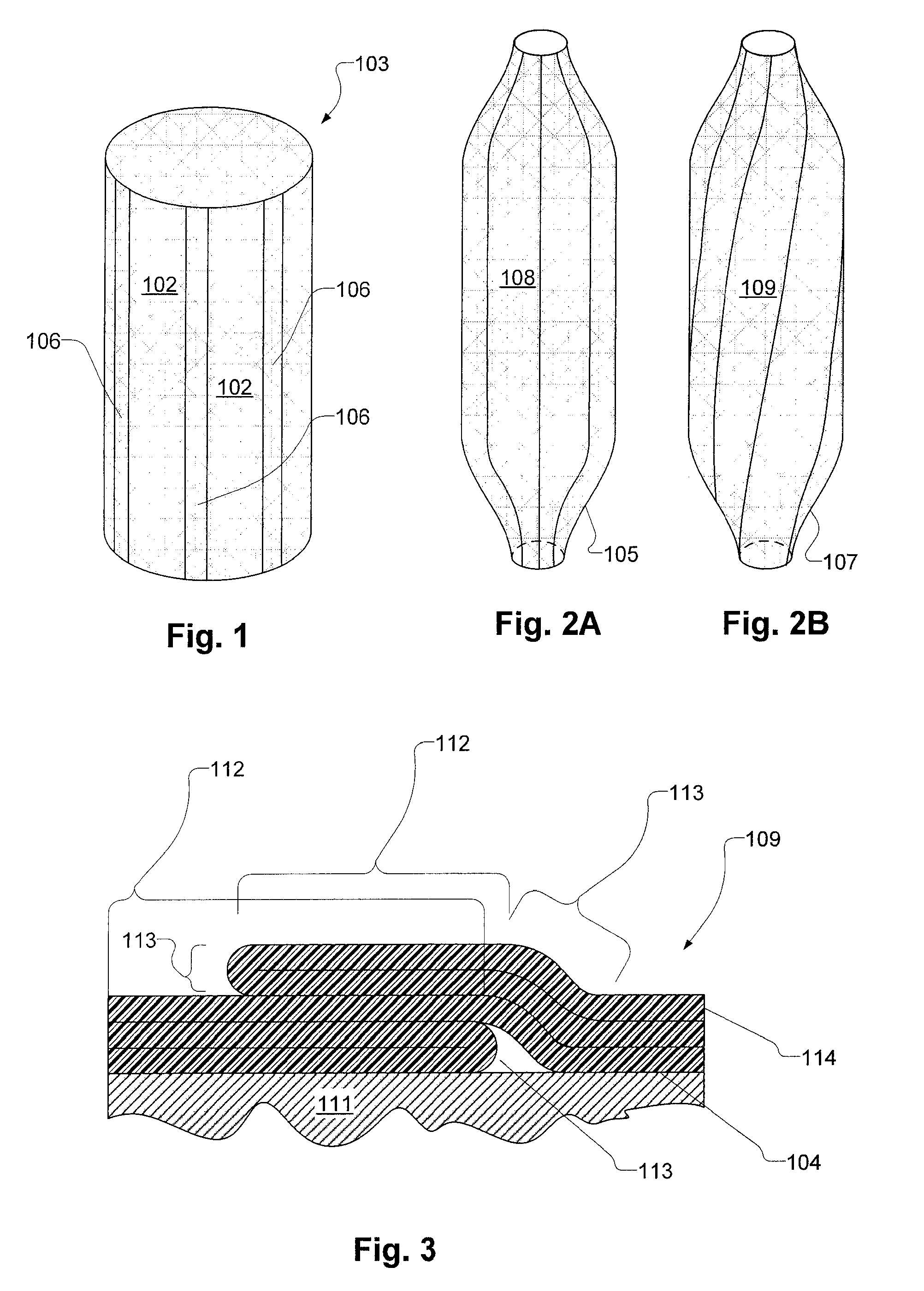

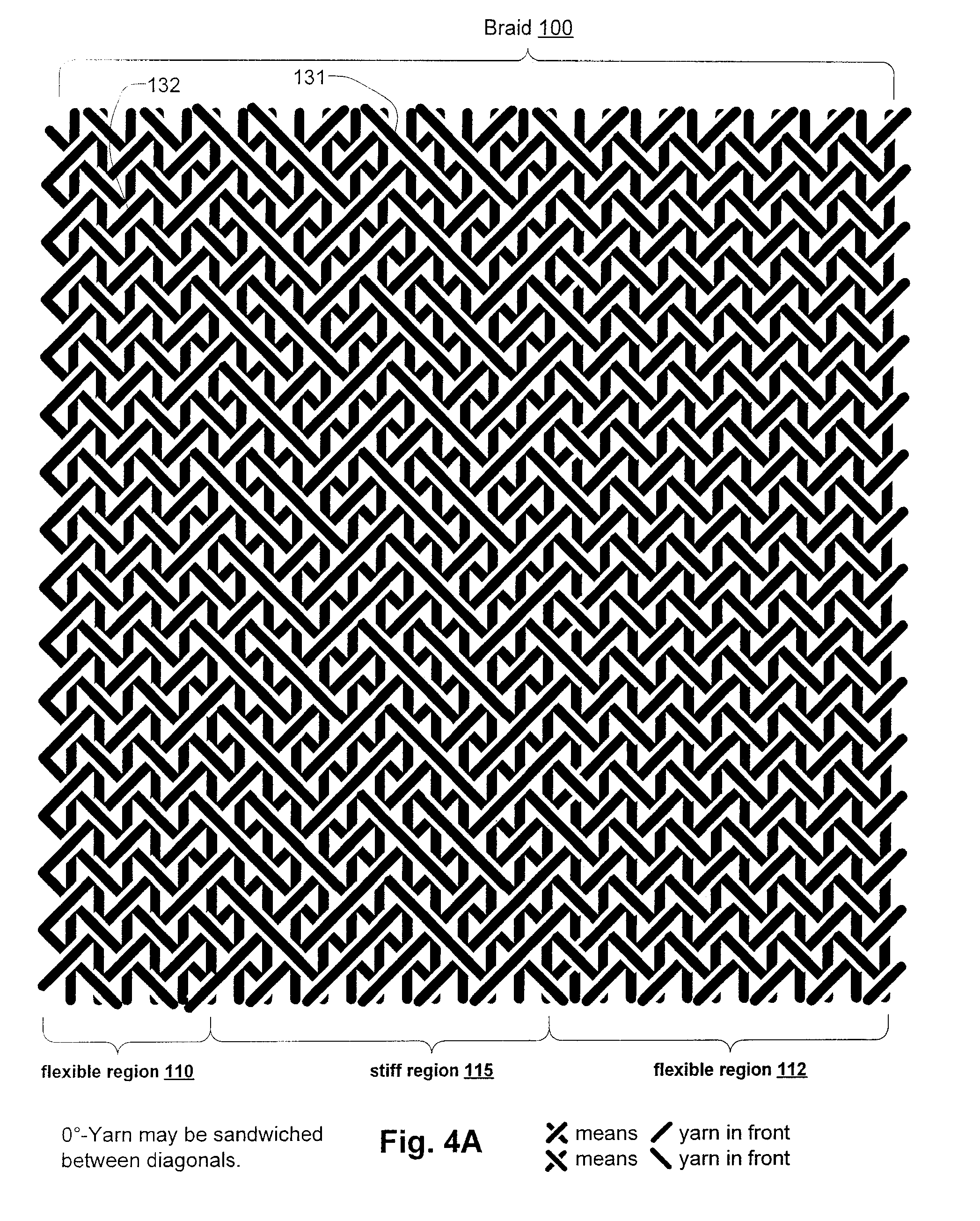

[0061]FIG. 1 shows a reinforcement structure, such as a tube braid, that may be used in a composite balloon, the reinforcement structure having relatively flexible portions 106 or facets and relatively stiff portions 102 or facets. A tubular braid 103 has stiff portions 102 that are relatively stiff, or at least relatively stiff in the circumferential direction (i.e., the direction about the balloon axis). The tubular braid 103 also has flexible portions 106 that are flexible relative to the stiff portions 102, also, at least in the circumferential direction.

[0062]The tube braid 103 may be of strong filaments (not shown separately) of any type, but in the present embodiments of folding medical balloons, they include relatively inelastic high strength synthetic fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com