Separation membrane for membrane distillation

a separation membrane and membrane technology, applied in the direction of membranes, separation processes, filtration separation, etc., can solve the problems of large energy consumption, reverse osmosis process, evaporation process and reverse osmosis process, etc., and achieve the effect of increasing the yield of treated water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]Hereinafter, a detailed description will be given of the present invention.

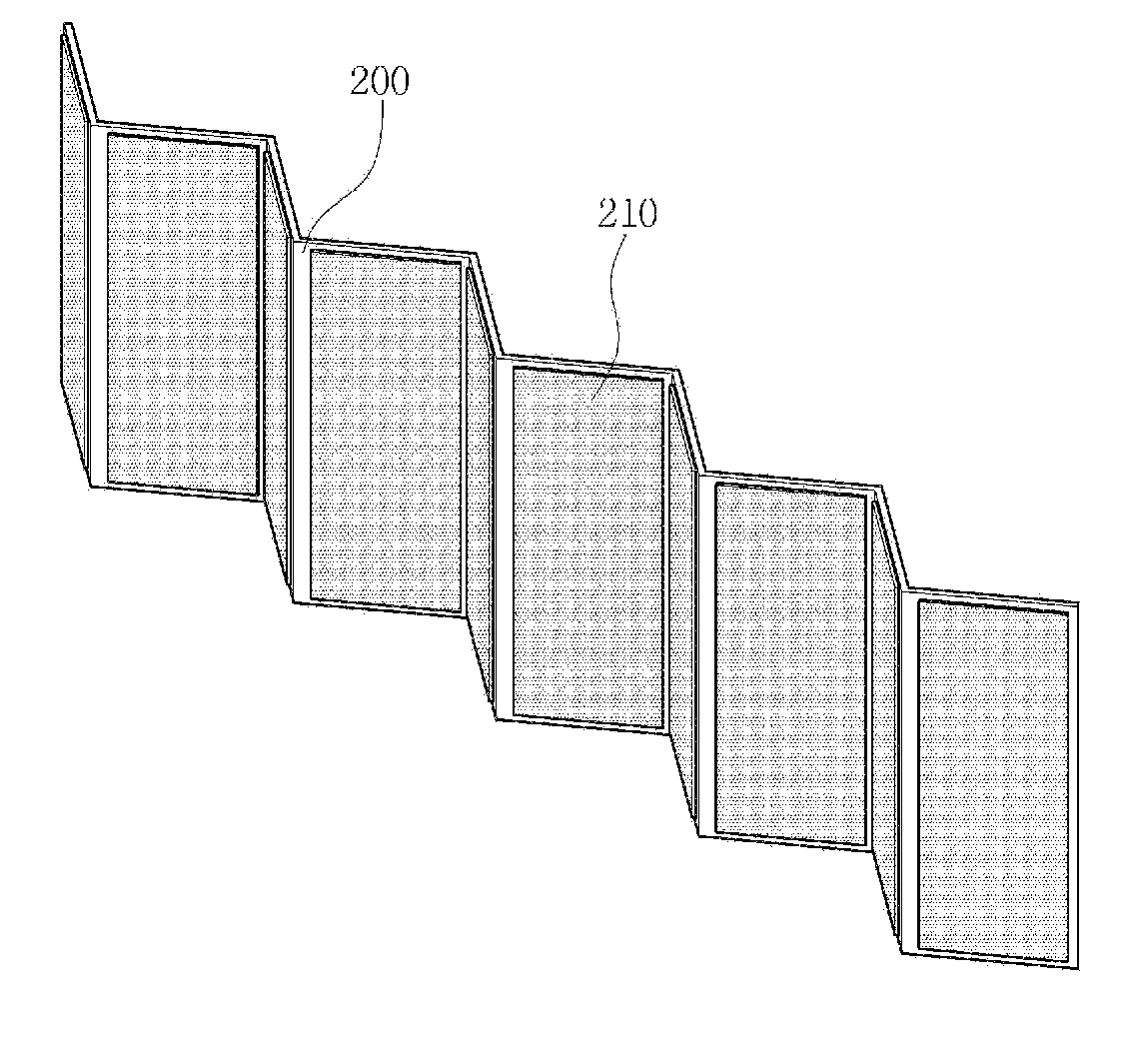

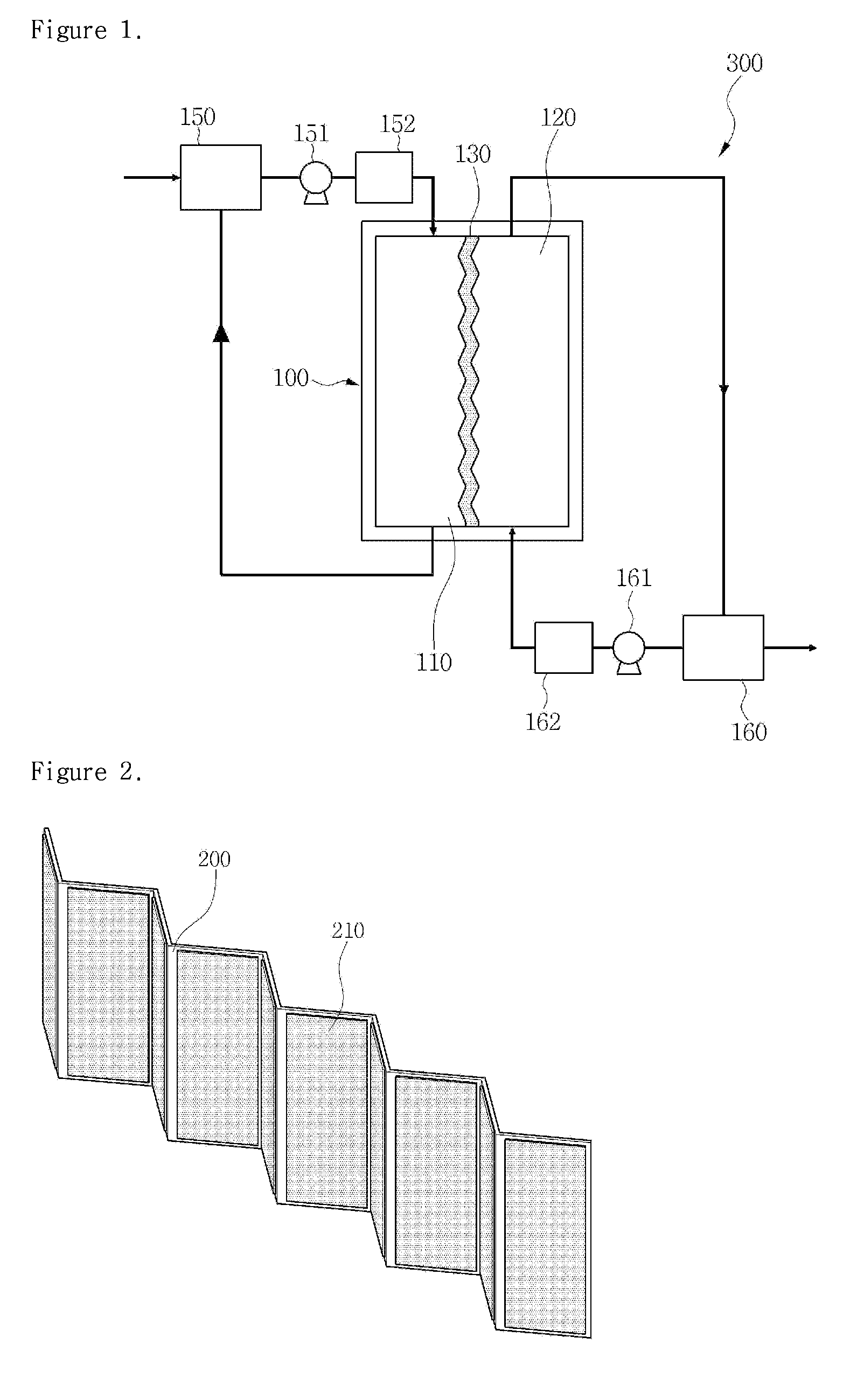

[0025]The present invention pertains to a separation membrane for membrane distillation. More specifically, the present invention pertains to a separation membrane for membrane distillation including a feed water side for feeding raw water and a treated water side for discharging treated water, wherein the separation membrane is provided in bent form by a support frame.

[0026]In the present invention, the separation membrane is preferably a hydrophobic polymer separation membrane. The reason why the hydrophobic polymer separation membrane is used is as follows: a solvent or solute (a hydrophilic material) in a liquid phase, having a surface tension greater than that of the separation membrane, does not pass through membrane pores but is repelled from the surface of the separation membrane, and thus, the separating material is converted into a vapor phase at the entrances of the surface pores of the separ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com