Tubular heating-pipe solar water-heating-system with integral tank

a solar water heating and solar energy technology, applied in the safety of solar heat collectors, solar heat collectors, solar heat storage, etc., can solve the problems of reducing the efficiency of heat collection, slowing down the natural thermosyphon flow, and relatively stagnant hot water flow in the upper manifold, so as to improve the heat collection efficiency, and boost the heating capacity of the existing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

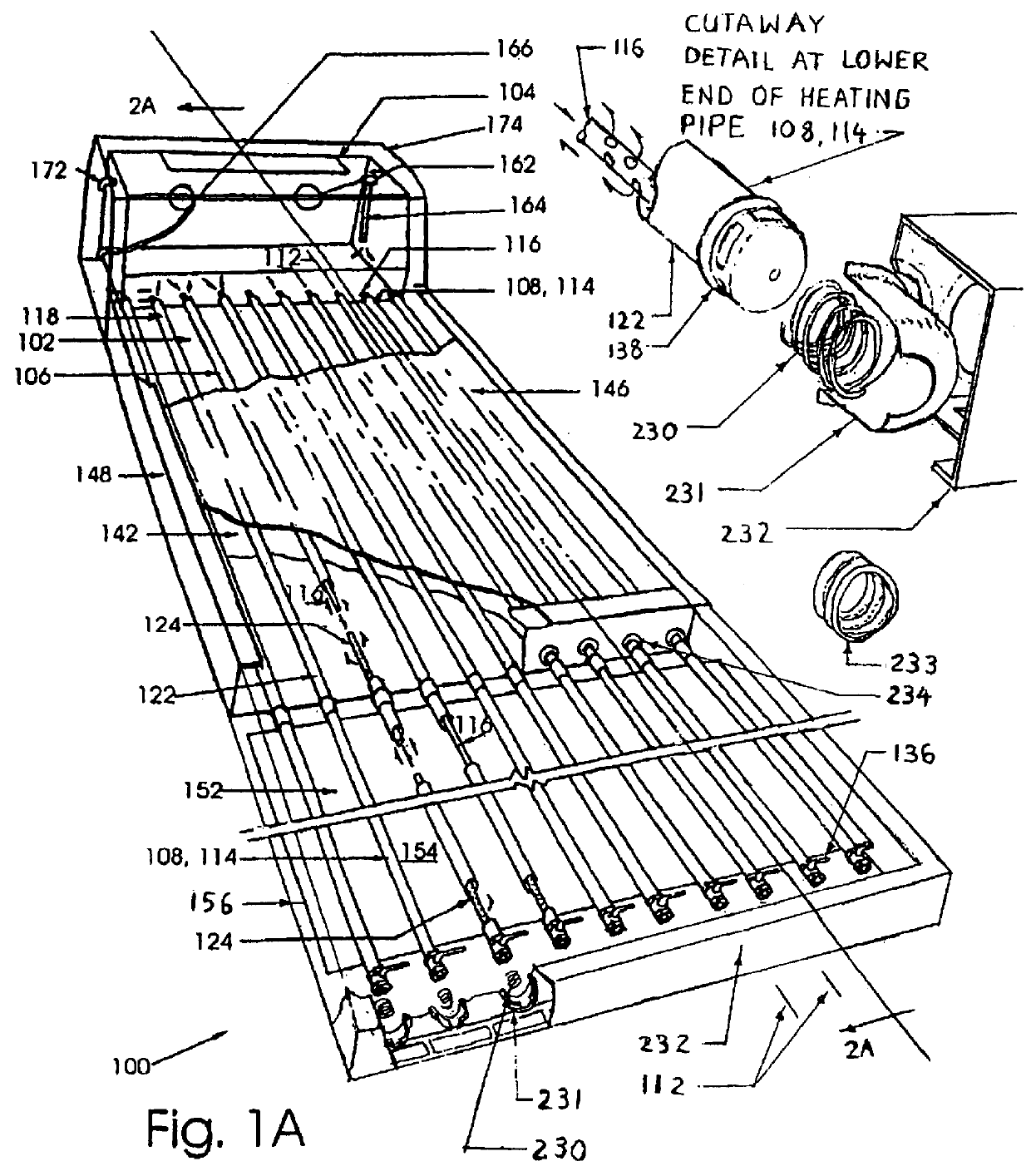

[0032]FIG. 1A depicts a solar water-heating-system in accordance with the present invention referred to by the general reference character 100. The solar water-heating-system 100 includes a solar water-heating-panel 102 directly connected to an insulated hot-water storage-tank 104. The solar water-heating-panel 102 includes a collector core 106 assembled from a plurality of heating-pipes 108. The heating-pipes 108 have longitudinal axes 112 that are arranged substantially parallel.

[0033]The heating-pipes 108 are free to move longitudinally to accommodate thermal expansion and contraction. The middle portions of the heating-pipes 108 are loosely secured by low friction sleeve collars 234 to the solar water-heating-panel casing 148 or frame 232 with the lower ends of the heating-pipes loosely secured or seated on a spring 230 or flexible corrugated polymer hose seat 233 in a cup 231 fixed onto the casing 148 or frame 232.

[0034]The heating-pipes 108 are preferably spaced equidistantly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com