Scroll type compressor having curved surface portions between the shaft and bearing means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

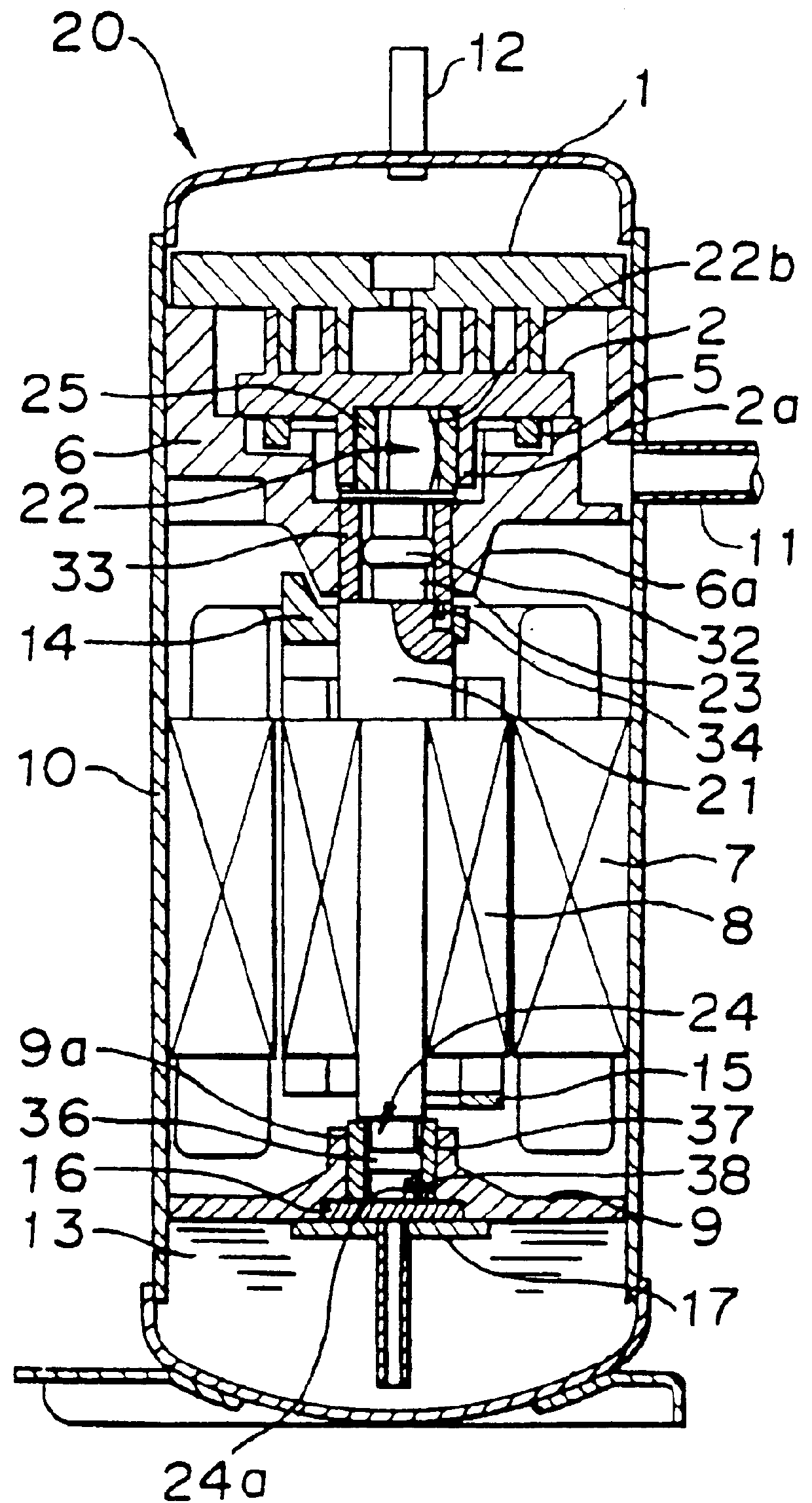

The scroll type compressor according to the present invention will be described in detail, referring to embodiments shown in the accompanying drawings. In FIG. 1, there is shown the scroll type compressor 20 according to a first embodiment of the present invention. In FIG. 1 showing the scroll type compressor 20 of the first embodiment, similar or corresponding parts are indicated by the same reference numerals as the conventional scroll type compressor shown in FIG. 17, and explanation of those parts will be omitted for the sake of simplicity.

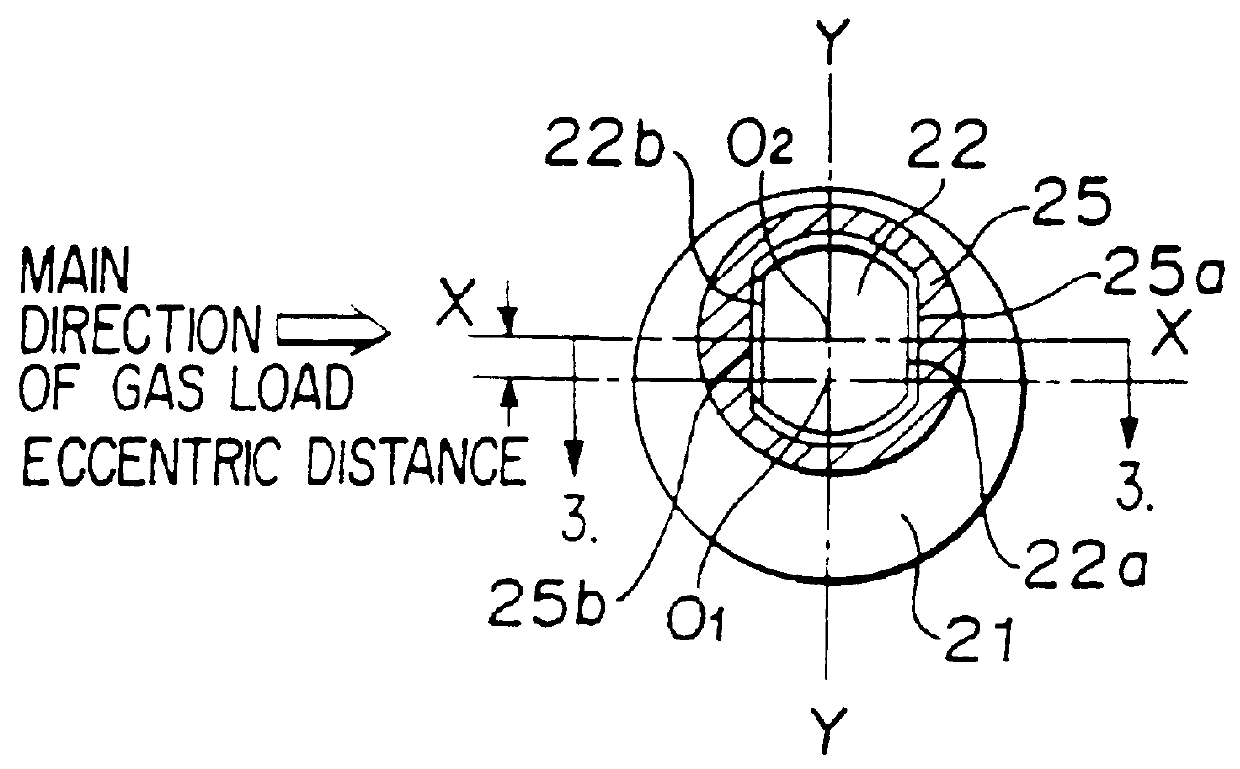

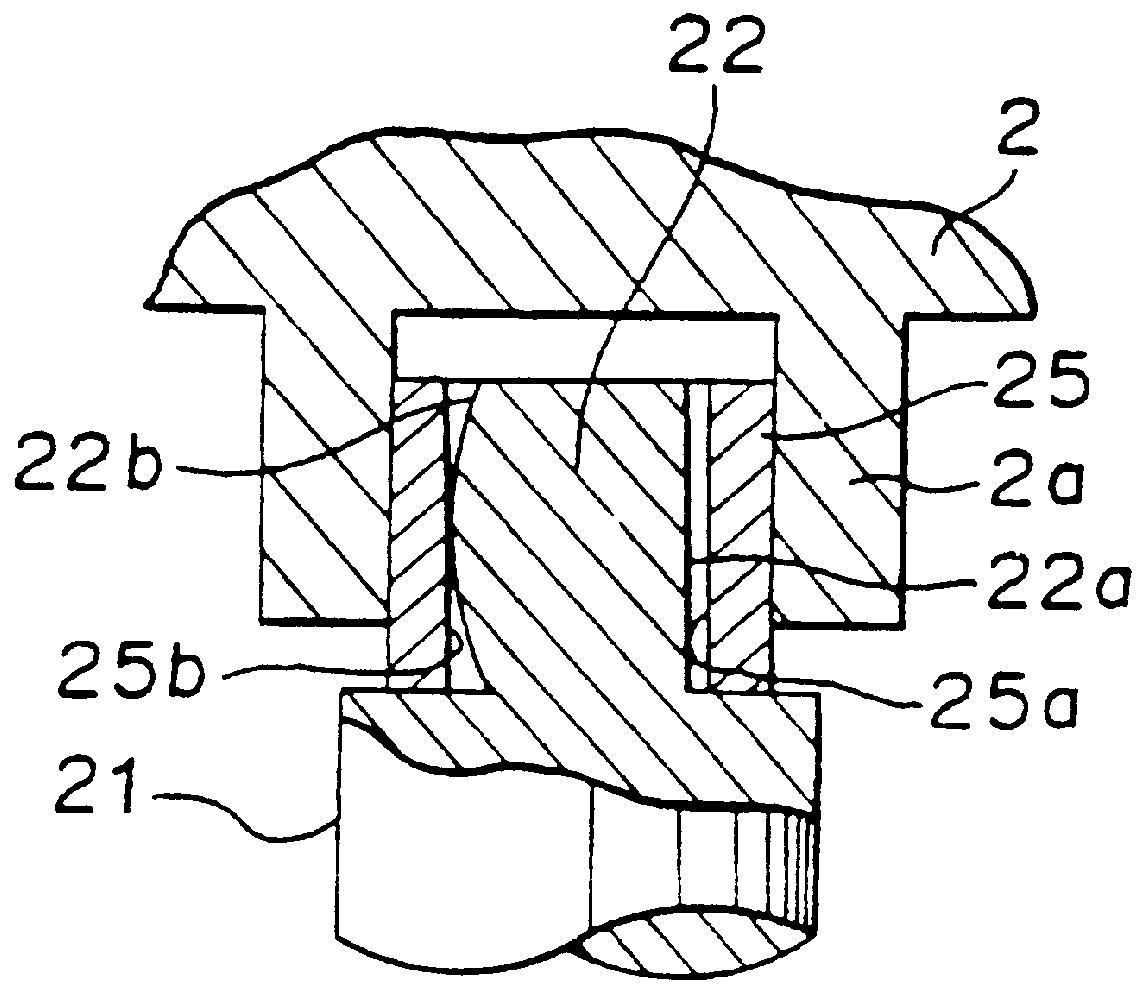

The scroll type compressor 20 of the embodiment includes a crankshaft 21 which has an electric motor rotor 8 fixed by shrinkage fit at an intermediate portion thereof in its axial direction. The crankshaft 21 has an upper portion formed integrally with an eccentric shaft portion 22 which is fitted into a bearing part 2a of an orbiting scroll 2 to give torque directly to the orbiting scroll 2. The crankshaft has a main shaft portion 23 formed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com