Modularized assembly for bulk material analyzer

a technology of bulk material analyzer and module, which is applied in the direction of instruments, machines/engines, specific gravity measurement, etc., can solve the problem of difficult transportation of assembly, and achieve the effect of convenient handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

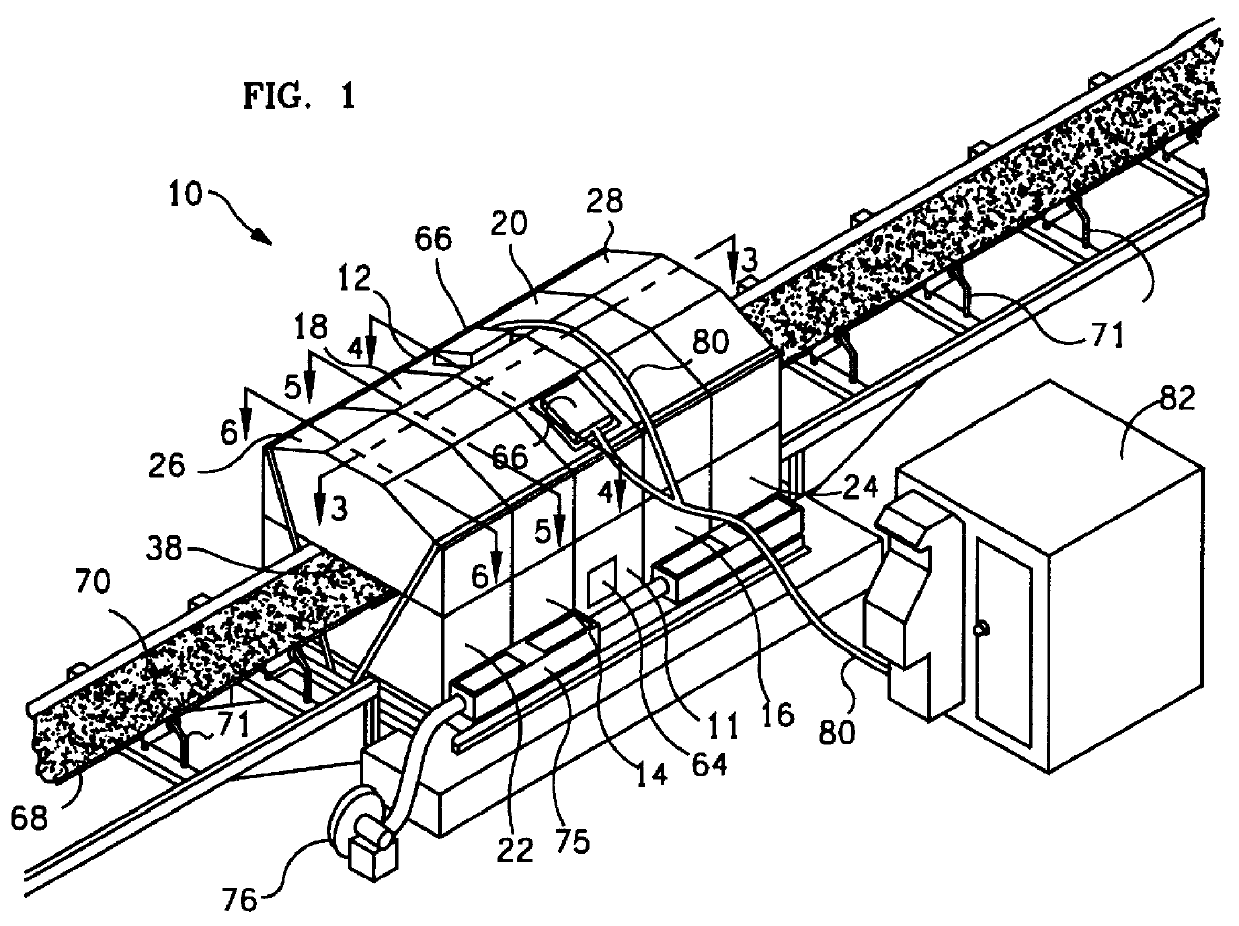

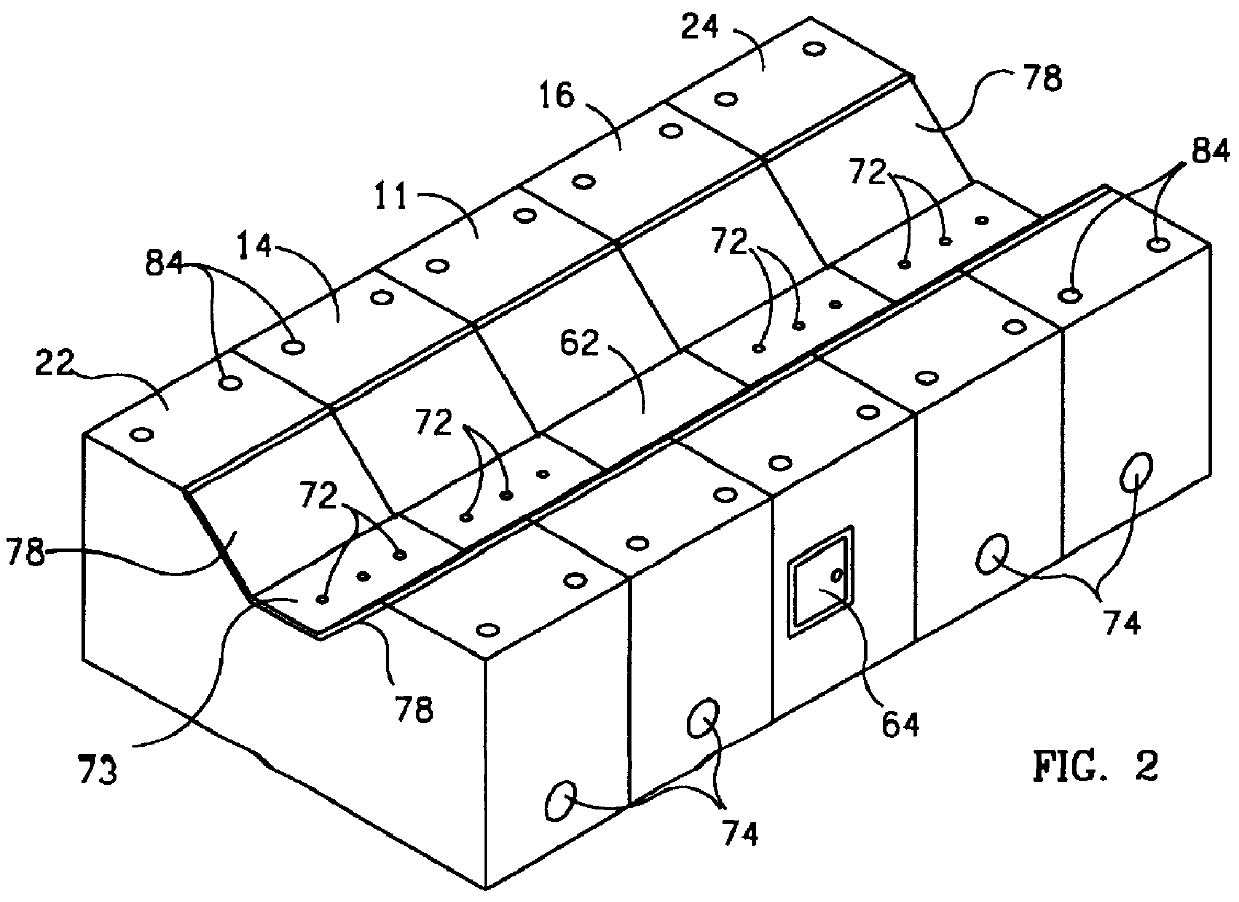

Referring to FIGS. 1 and 2, a preferred embodiment of the bulk material analyzer assembly 10 of the present invention includes a lower primary module 11, an upper primary module 12, a first lower secondary module 14, a second lower secondary module 16, a first upper secondary module 18, a second upper secondary module 20, a first lower tertiary module 22, a second lower tertiary module 24, a first upper tertiary module 26 and a second upper tertiary module 28.

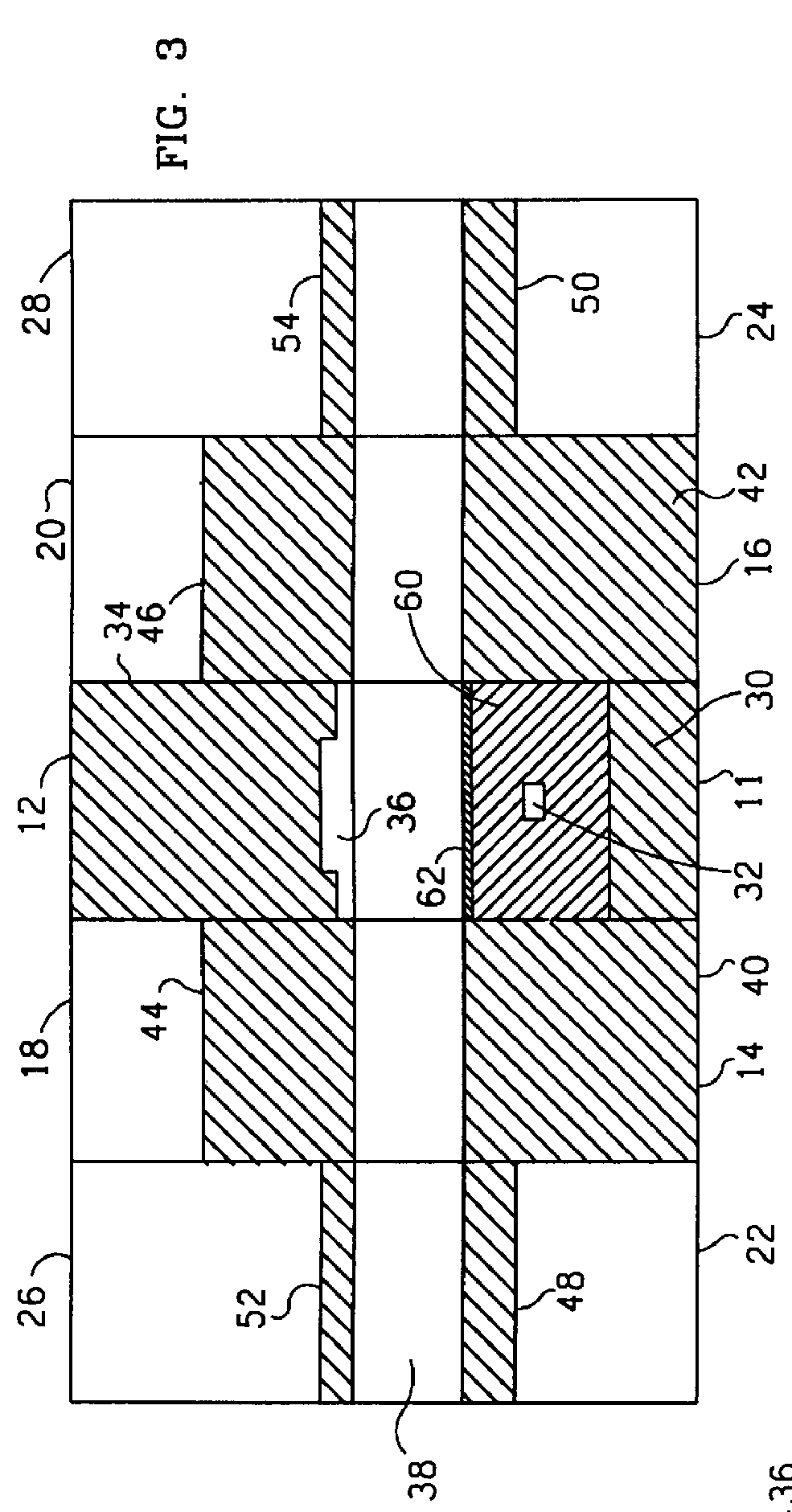

The lower primary module 11 contains a first portion of radiation shielding material 30 and defines a pair of radiation source cavities 32 for receiving neutron sources 33, as shown in FIGS. 3 and 4. The upper primary module 12 contains a second portion of radiation shielding material 34 and defines a pair of radiation detector cavities 36 for receiving gamma-ray detectors 37, as also shown in FIGS. 3 and 4. The lower primary module 11 and the upper primary module 12 are so shaped that the upper primary module 12 can be placed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shielding | aaaaa | aaaaa |

| radiation shielding | aaaaa | aaaaa |

| energy spectra | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com