Enhanced tubular heat exchanger

a technology of heat exchanger and tube, which is applied in the direction of indirect heat exchangers, lighting and heating apparatus, heating types, etc., can solve the problems of inefficiency in the amount of heat transferred from heated flue gases to circulating air, and the flow in the center may only be minimal, so as to achieve efficient heat transfer, promote circulation air flow, and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

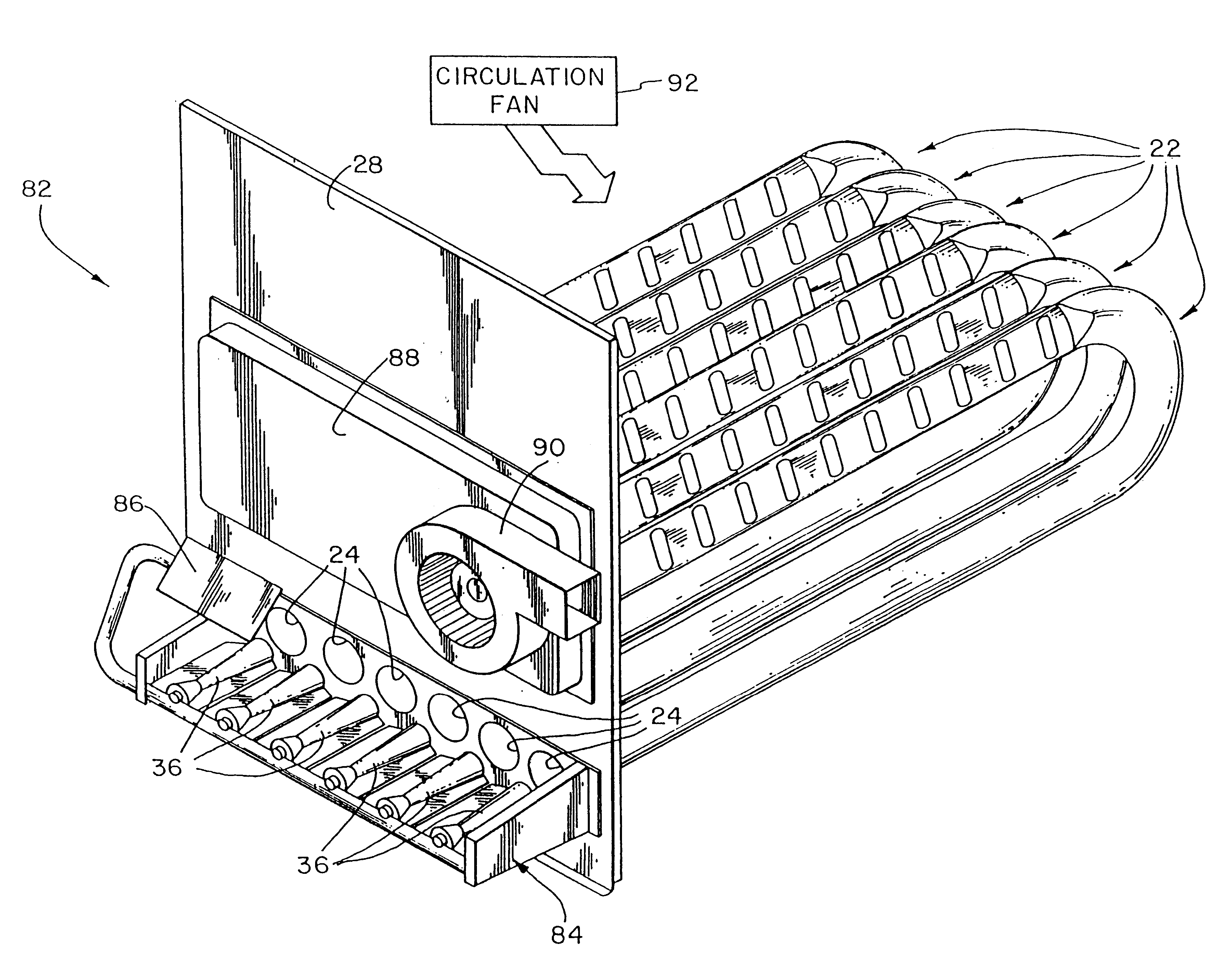

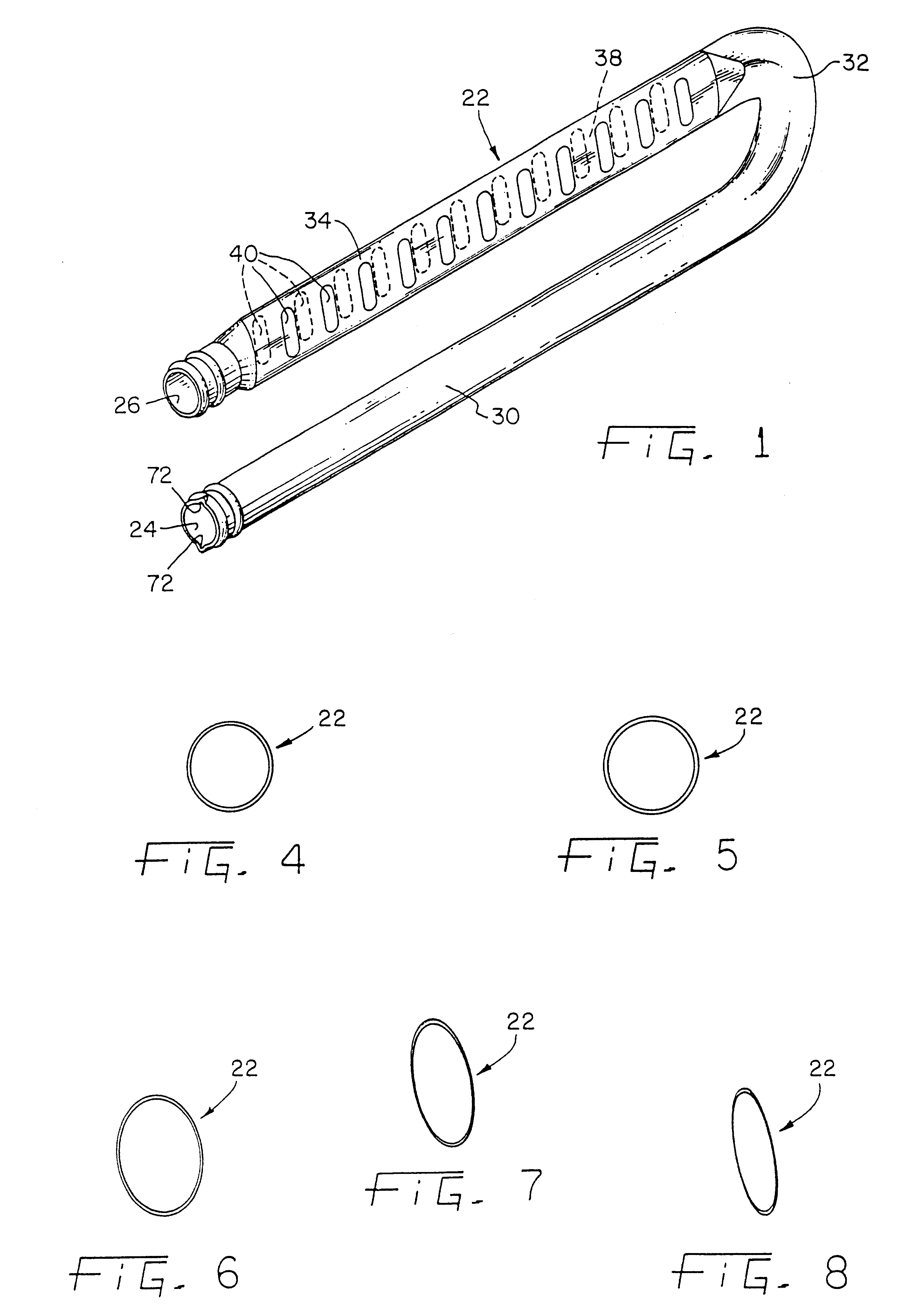

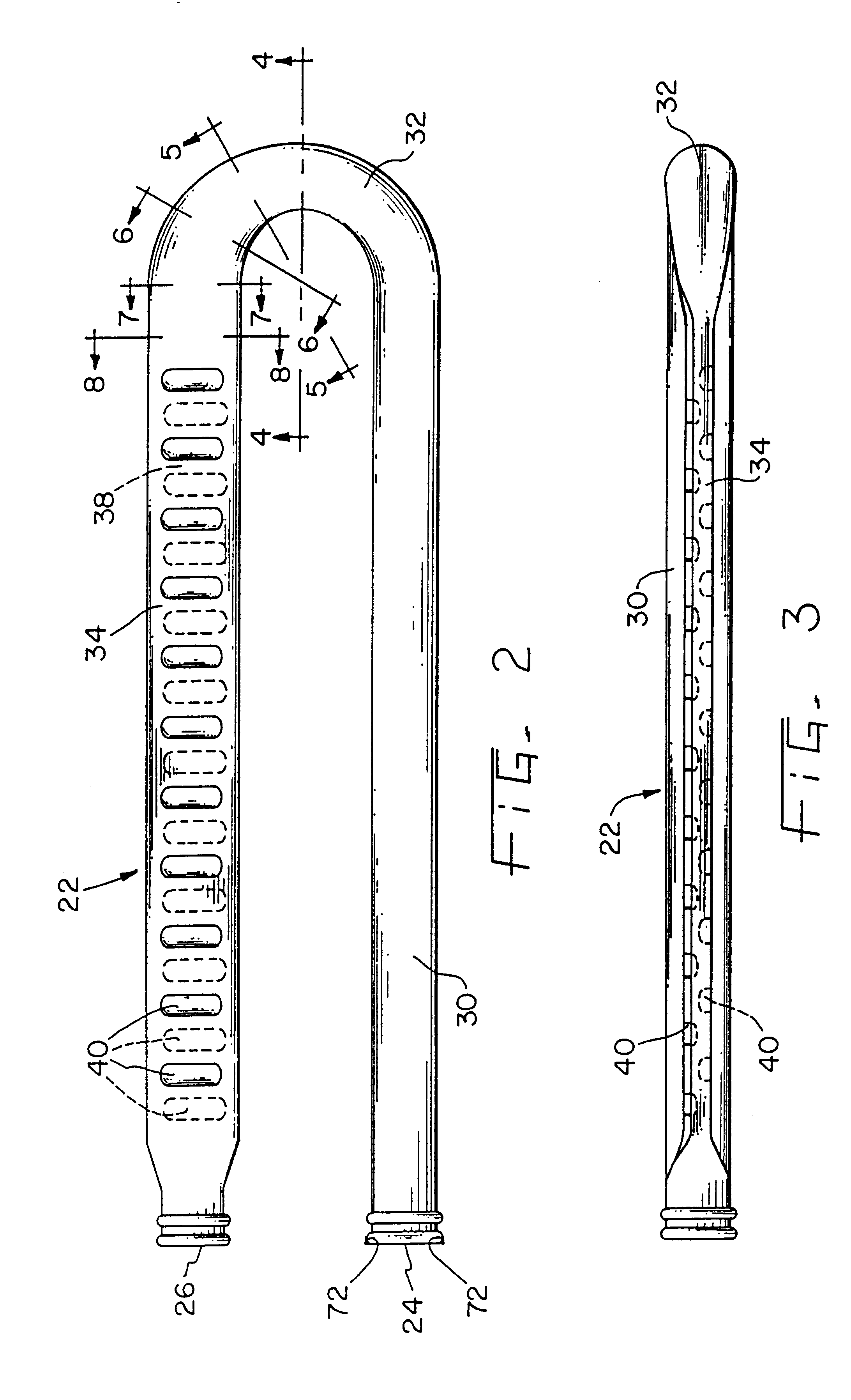

The present invention relates to an elongated heat exchanger tube 22 as depicted in FIG. 1. Tube 22 includes inlet 24 and outlet 26 for attaching to a heat exchanger panel 28 (see FIGS. 9 and 10). Connecting inlet 24 and outlet 26, tube 22 includes flue portion 30 which is adjacent to inlet 24, bend portion 32 which is adjacent to flue portion 30, and enhanced portion 34 which is disposed between bend portion 32 and outlet 26. Flue portion 30 is generally cylindrical in shape and receives the flame which is produced by operation of inshot burner 36 (see FIG. 9).

In accordance with the present invention, bend portion 32 decreases in cross-sectional area approaching enhanced portion 34, see FIGS. 2 and 4-8. Enhanced portion 34 is considerably narrower than flue portion 30, compare FIGS. 4 and 8 (although FIG. 4 shows a cross-section of bend portion 32, the depicted shape is representative of the general cross-sectional shape of flue portion 30). The narrowness of enhanced portion 34 pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com