Wafer polishing method and apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

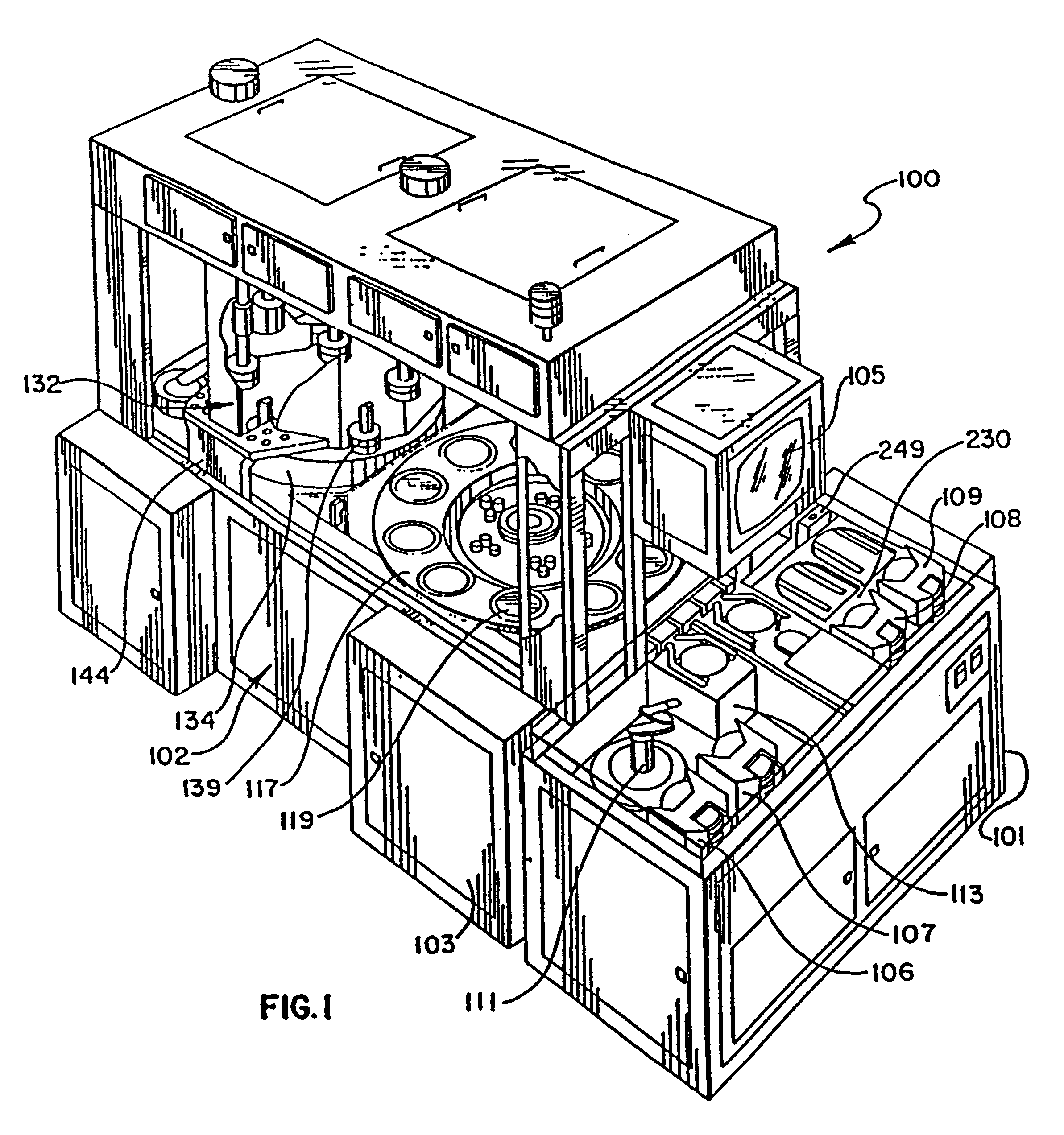

FIG. 1 is a perspective view of a wafer polishing apparatus 100 embodying the present invention. Wafer polishing apparatus 160 includes a wafer input / output module 101 and a wafer process module 102. The wafer polishing apparatus 100 is constructed so that input / output module 101 can be placed, for example, inside a class 10 clean room environment while the process module 102 is placed beyond an adjacent wall perhaps in a class 1000 clean room environment. By means not specifically shown, air flow is created within the polishing system and the air pressures are regulated such that the environment of the class 10 clean room is not negatively influenced.

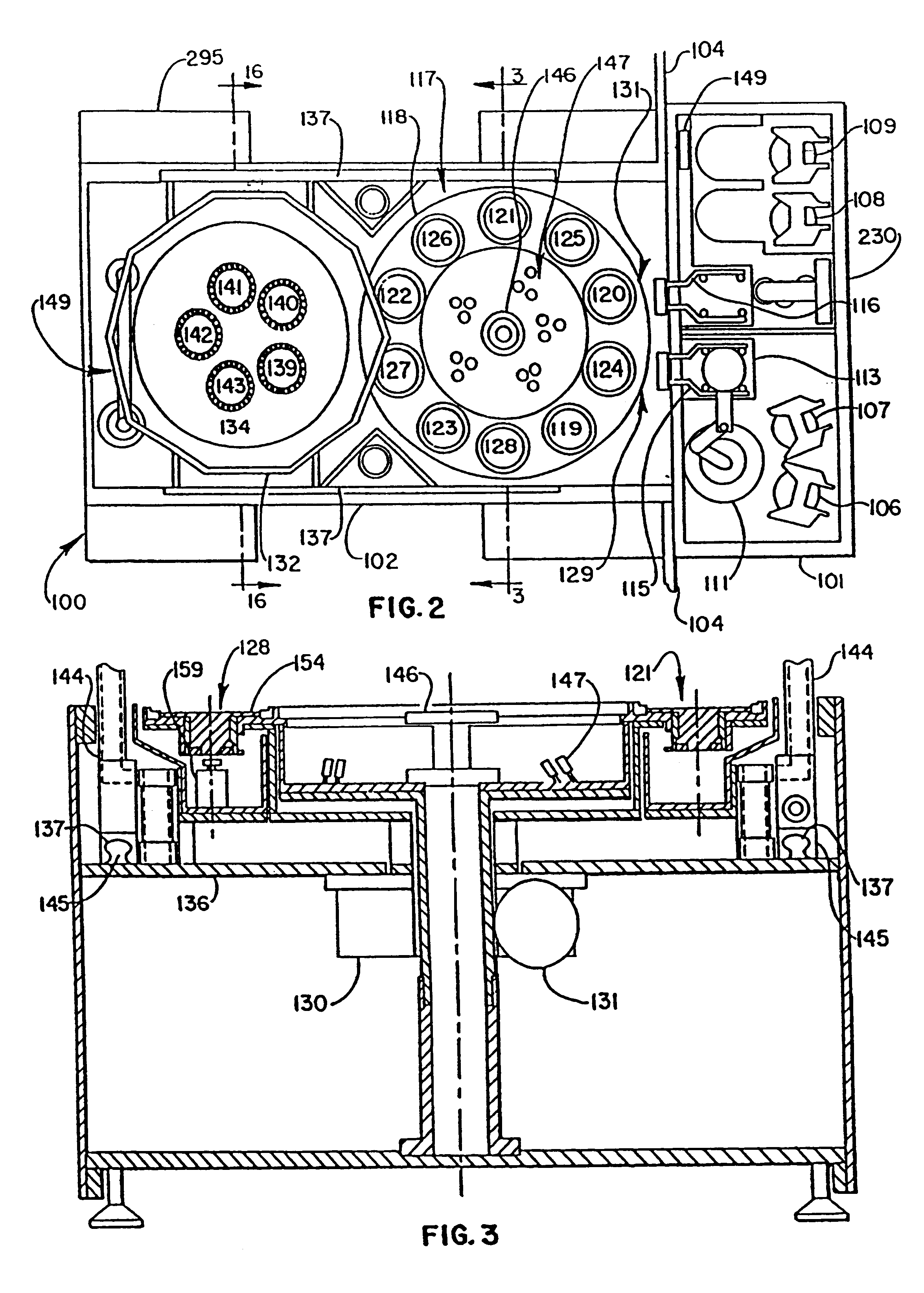

FIG. 2 is a top view of wafer polishing apparatus 100 in which the top and certain other structure of the perspective view has been removed for ease of understanding. Additionally in FIG. 2, a wall 104 is represented showing separation of input / output module 101 and process module 102 thereby. Wafers are presented to and removed from i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com