Refrigerated merchandiser with modular evaporator coils and EEPR control

a technology of evaporator coils and merchandisers, applied in the field of refrigeration art, can solve the problems of limiting the structural support capability of internal vertical frames, and achieve the effects of facilitating modular design and fabrication, reducing the size of coils, and increasing coil capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

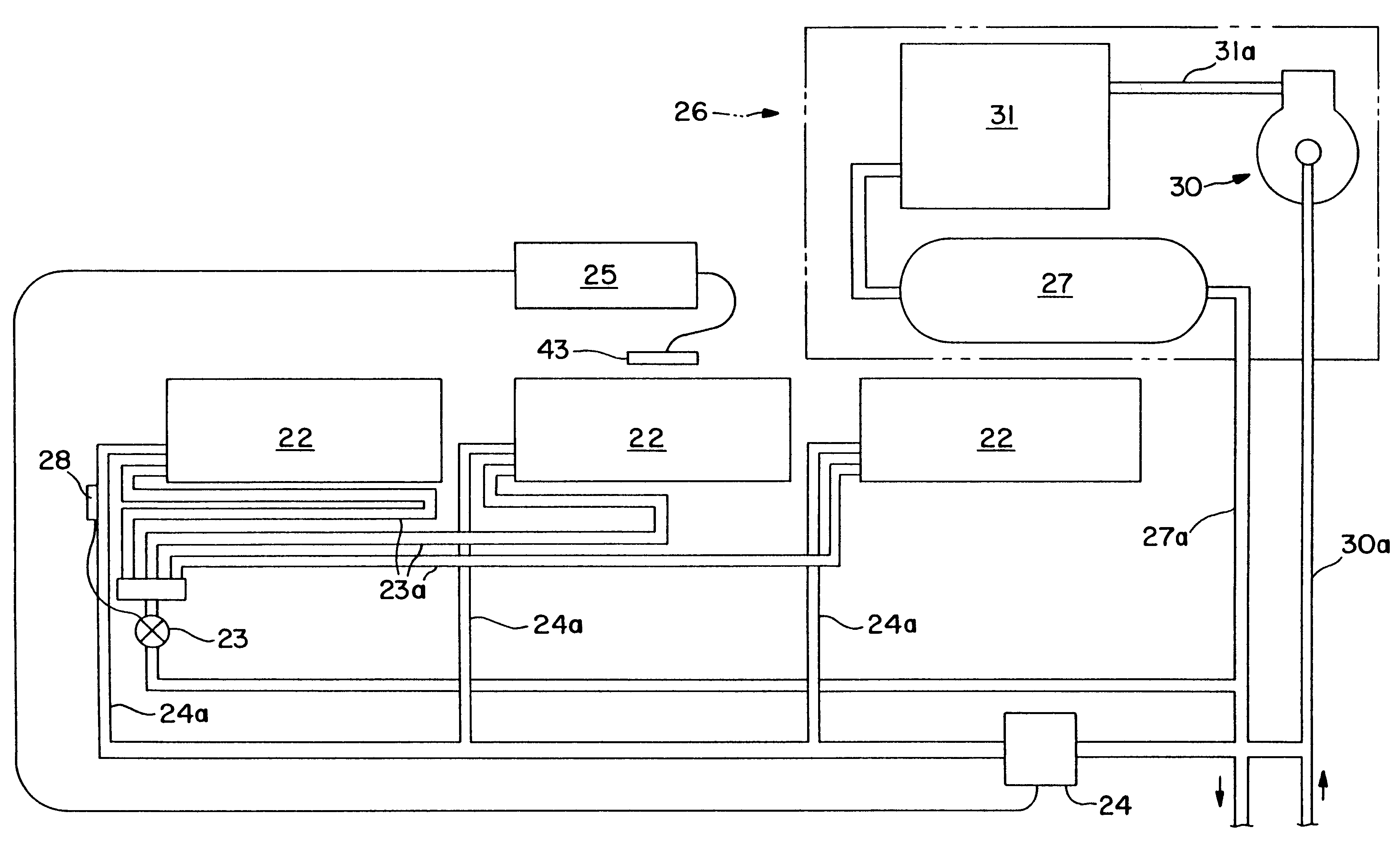

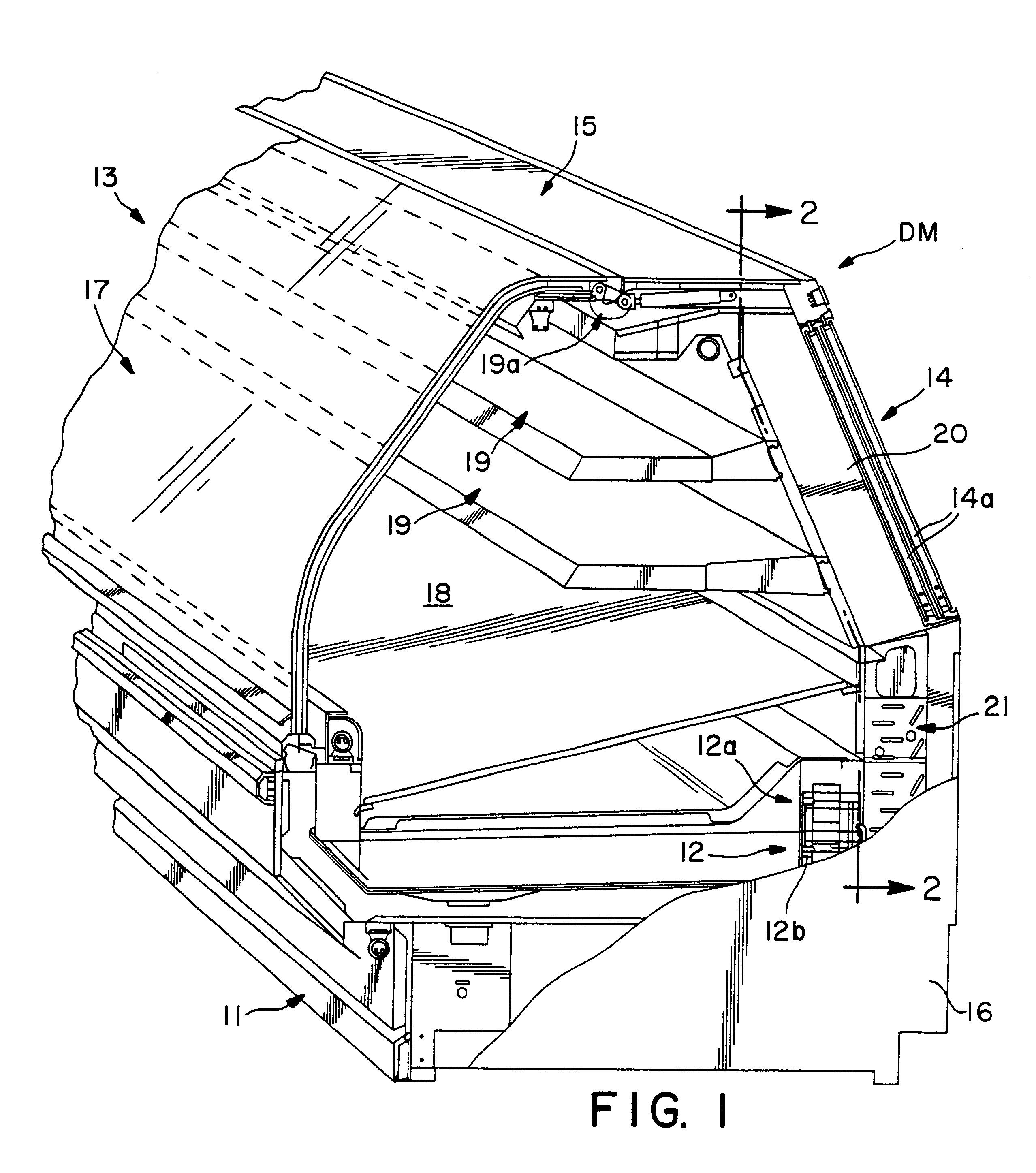

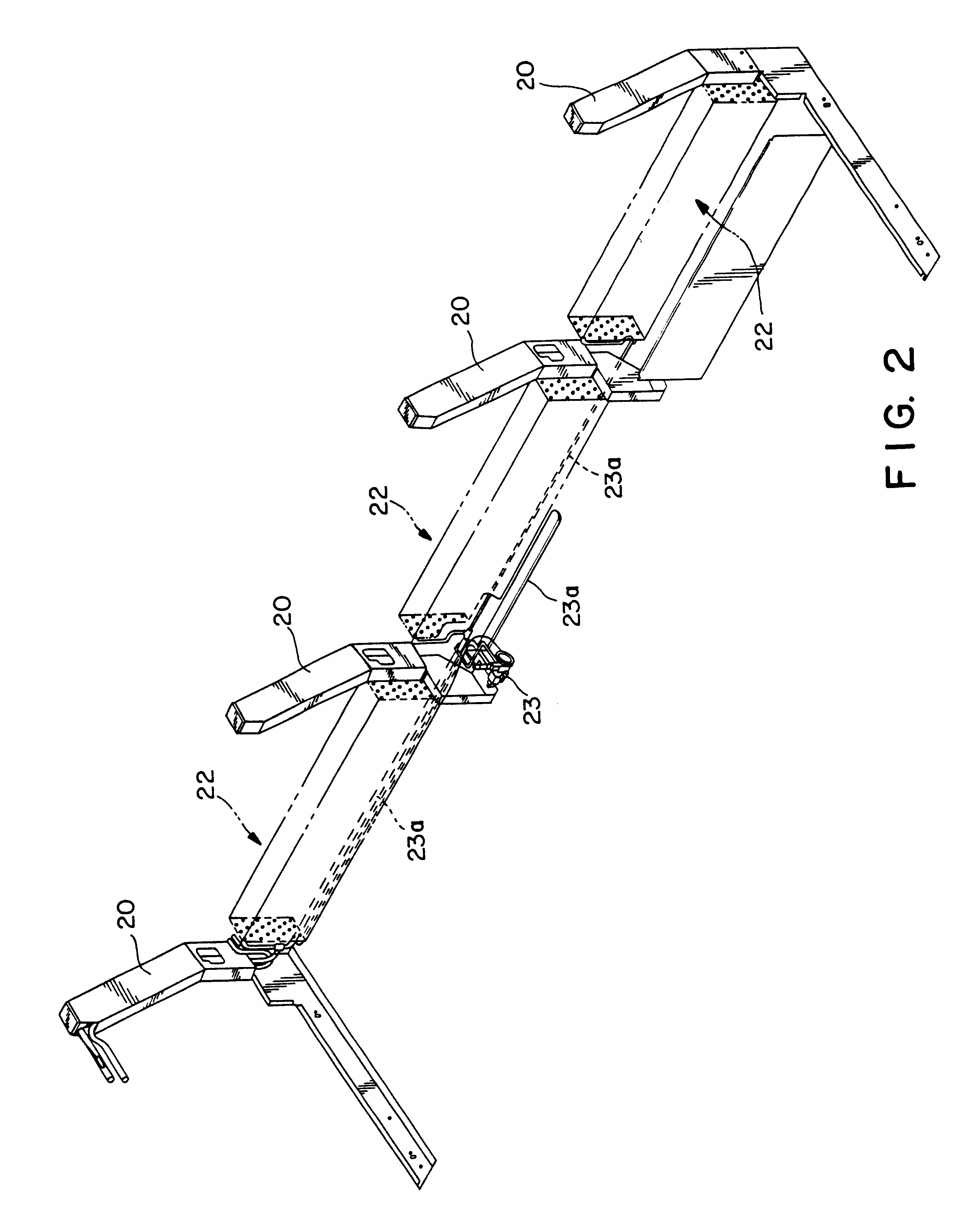

For disclosure purposes different embodiments of the modular evaporator coil and electronic evaporator pressure regulator (EEPR) control of the present invention are shown in different commercial food display cases or merchandisers as may be installed in a typical supermarket. Such display cases are generally fabricated in standard eight (8') foot and twelve (12') foot lengths, but may be arranged in a multiple case line-up of several merchandisers operating in the same general temperature range. Low temperature refrigeration to maintain display area temperatures of about 0.degree. F. for frozen foods requires coil temperatures generally in the range of -5.degree. F. to -20.degree. F. to achieve exit air temperatures at about -3.degree. F. to -11.degree. F.; and medium temperature refrigeration to maintain fresh food product area temperatures in the range of 34.degree. F. (red meat) to 46.degree. F. (produce) requires coil temperatures generally in the range of about 15.degree. F. t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com