Switch apparatus requiring the hand of the operator to activate the switch by breaking a light beam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

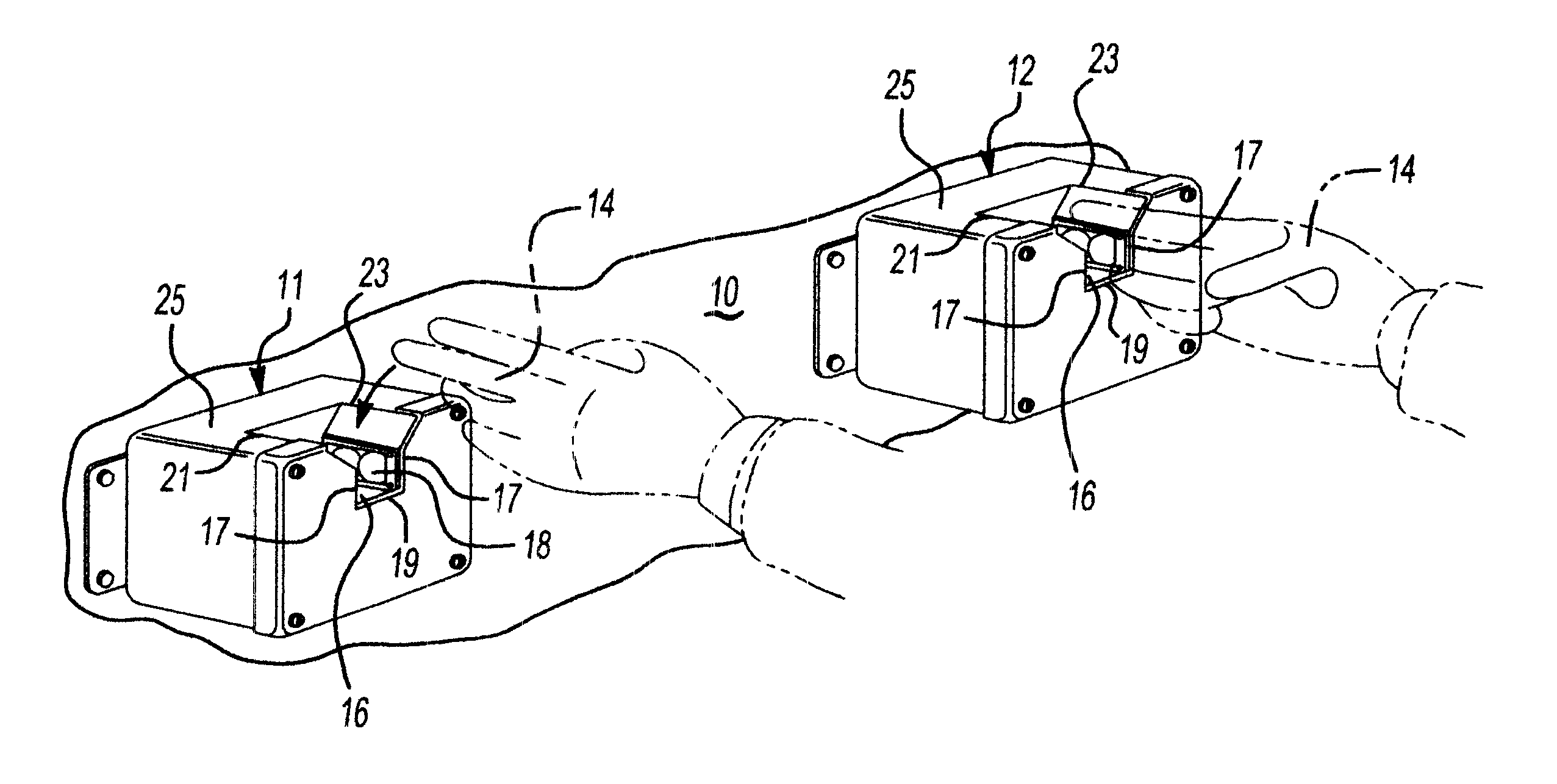

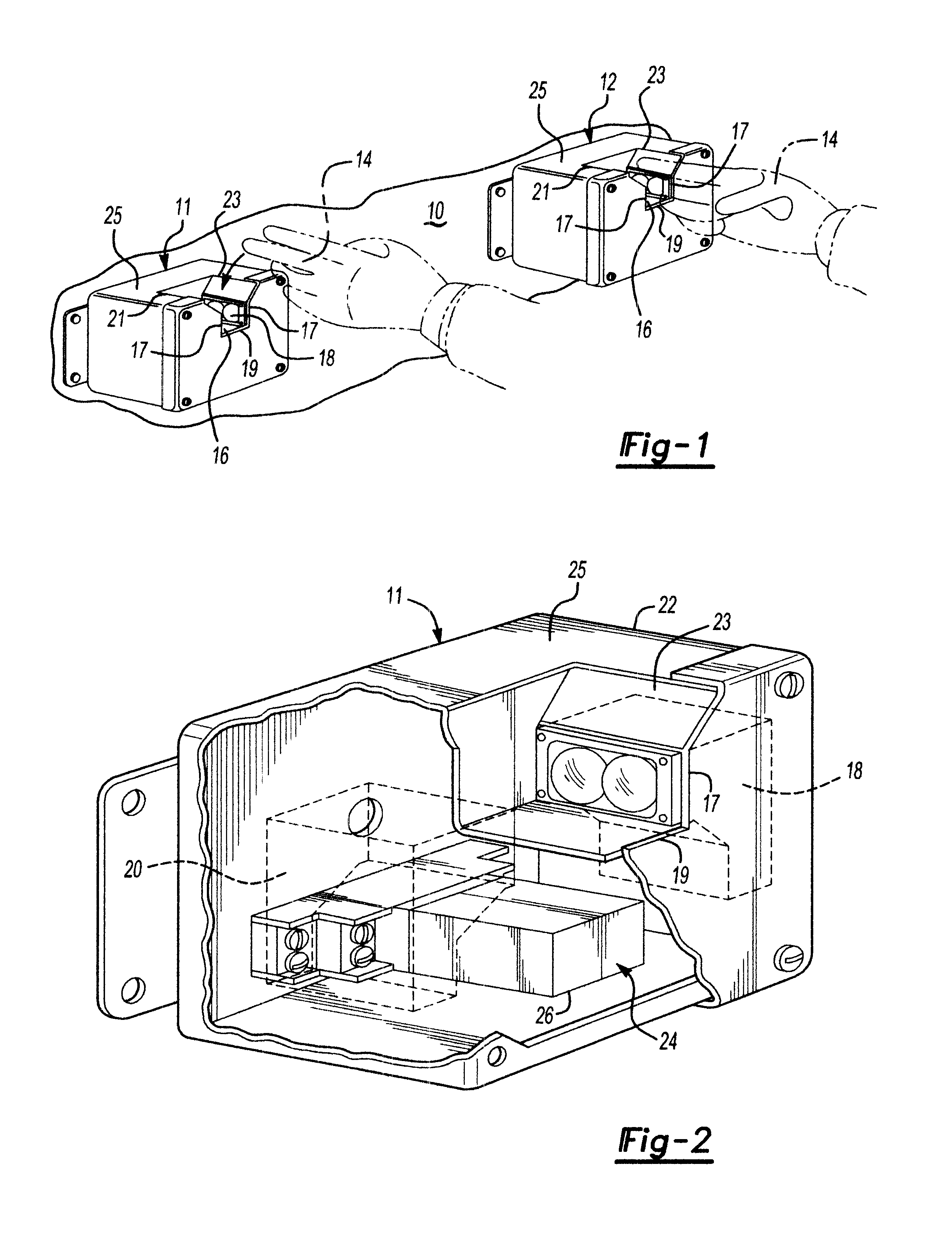

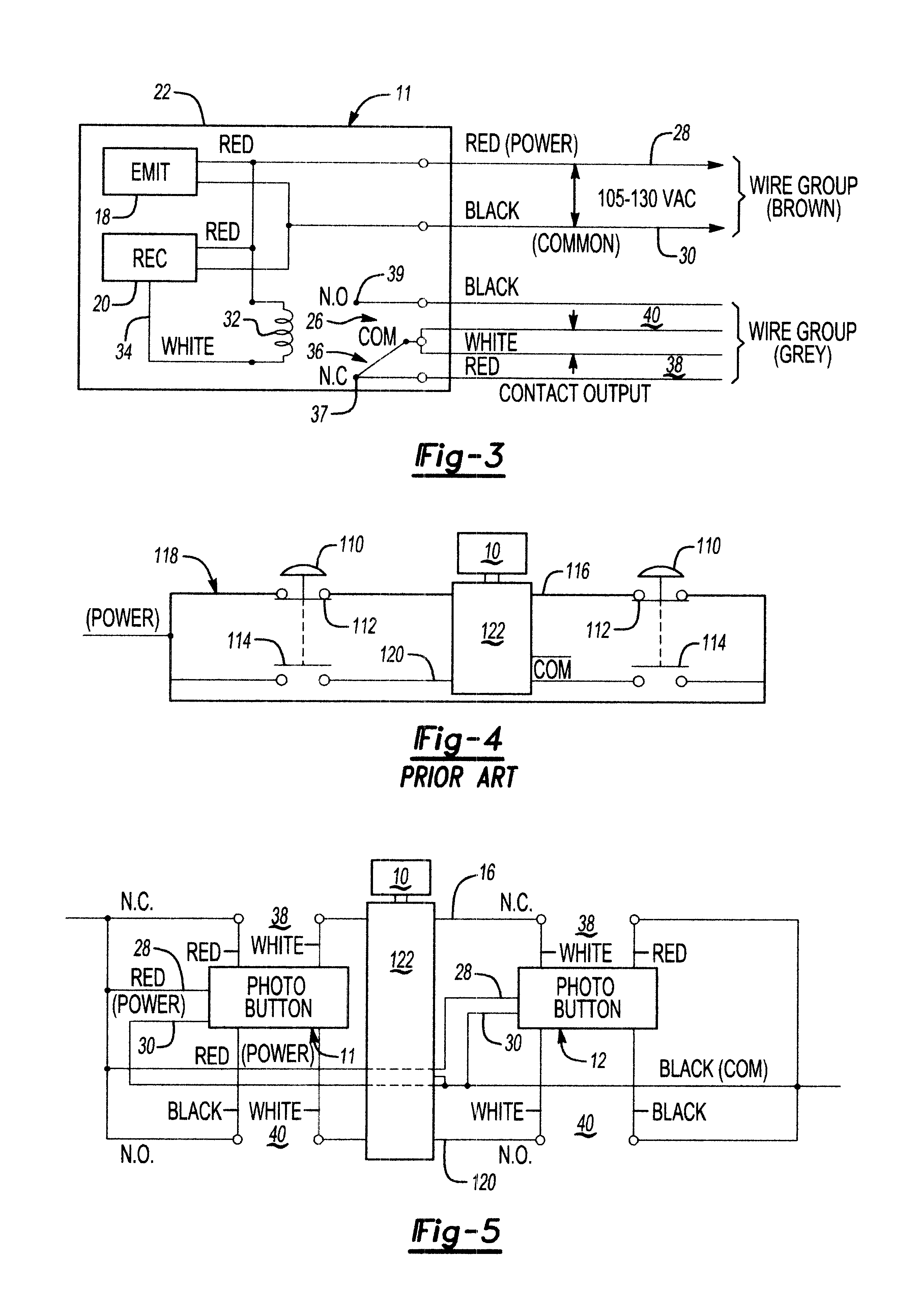

With reference first to FIG. 1, the manually operable switch apparatus of the present invention is thereshown positioned on the front of a machine 10 and first comprises a pair of actuation switches 11 and 12. The actuation switches 11 and 12 are characterized by being manually operable without the application of exertive contact against them. For example, the switches 11 and 12 are operable by the insertion of the fingers 14 of a machine operator into a slot 16 formed in each of the actuation switches 11 and 12. .Iadd.Slot 16 is preferably provided to act as a guide to the operator's hand. Specifically, slot 16 is formed by sides 17 spaced apart and extending vertically upward from a bottom 19 to form a generally U-shaped opening. Upper edges 21, 23 extend inwardly from the top 25 of the switch 11, 12 toward the bottom 19 of the slot 16. .Iaddend.An infrared beam is disposed across the slot 16, such that a mode of operation of the machine 10 is actuated when the beams of both switc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap