Rotary drive for a data carrier

a technology of rotary drive and data carrier, which is applied in the direction of motor/generator/converter stopper, dynamo-electric converter control, instruments, etc., can solve the problem of no longer arise the particularly critical problem of the heating of electronic components within the interior of the motor housing, and achieve the effect of shortening the axial length of the motor correspondingly, high resolution and added cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

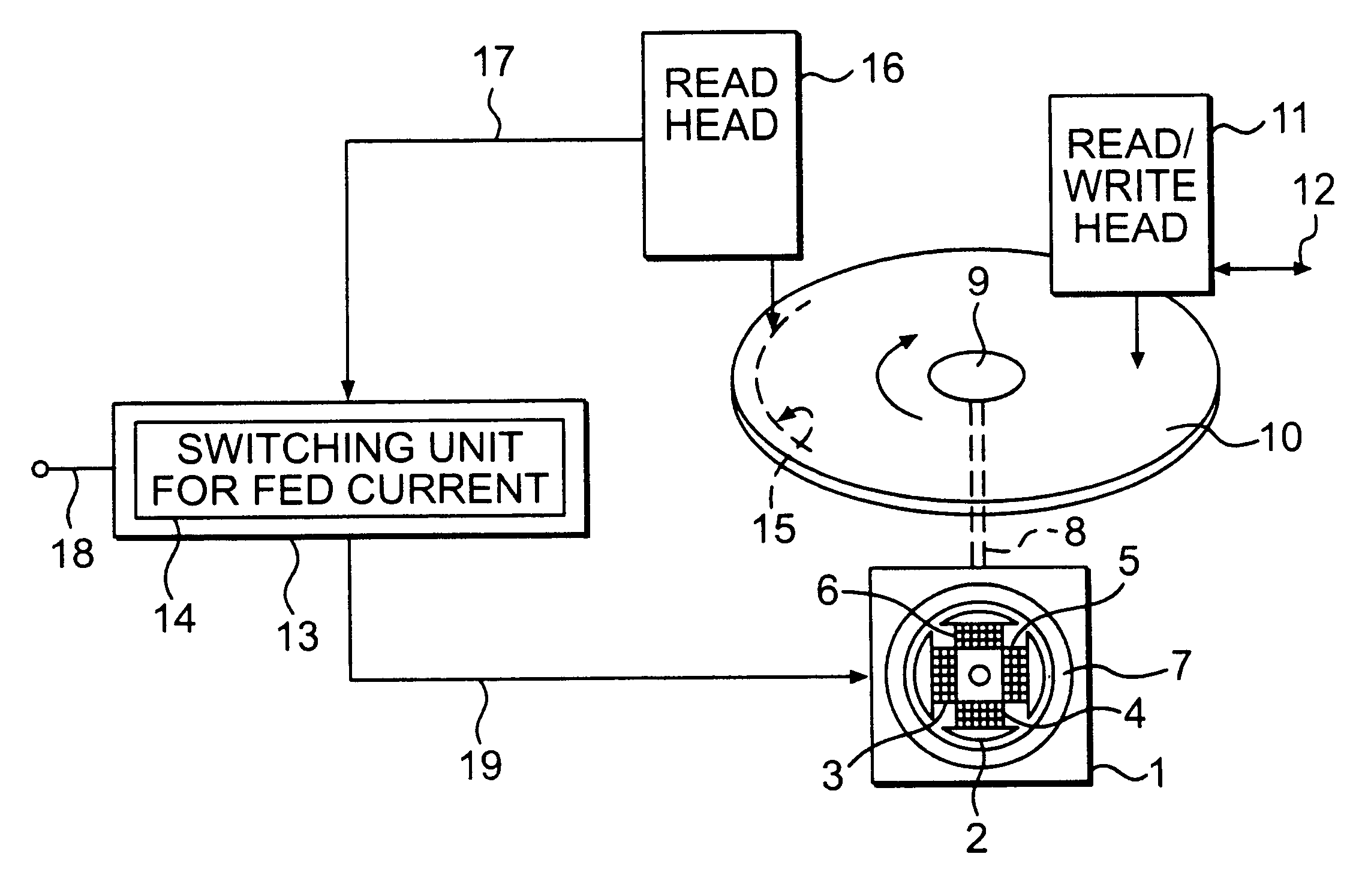

FIG. 1 depicts the principles of an exemplary embodiment having an external-rotor brushless d.c. motor 1. The four-pole stator 2 is provided with a winding made up of four coils 3-6 and is, in a known fashion, encircled by a permanent-coils magnet rotor 7.

For the sake of a simple illustration of inventive principles there is shown a external-rotor d.c. motor having an annular air gap; self-evidently, however, one can use any other motor type that would be suitable, in the sense of reduced axial length, a disk-rotor motor having a planar air gap being also preferred.

Rigidly connected to shaft 9 of motor 1 is a hub 9 on which a data carrier 10 is arranged. The data carrier 10 is constituted by a rigid or flexible computer data-storage platter carrying data signals a concentric trade. A write / read head 11 is arranged to be movable in radial direction war the data carrier 10; by means of head 11 data signals a the concentric tracks of data carrier 10 can be written, read, or erased. In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic field | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

| delay time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com