Remote brake release mechanism for an elevator machine

a technology of brake release mechanism and elevator machine, which is applied in the direction of elevators, hoisting equipment, transportation and packaging, etc., can solve problems such as difficulty in accessing locations, and achieve the effects of reducing braking force, reducing braking force, and limited and controlled movement of elevator cars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

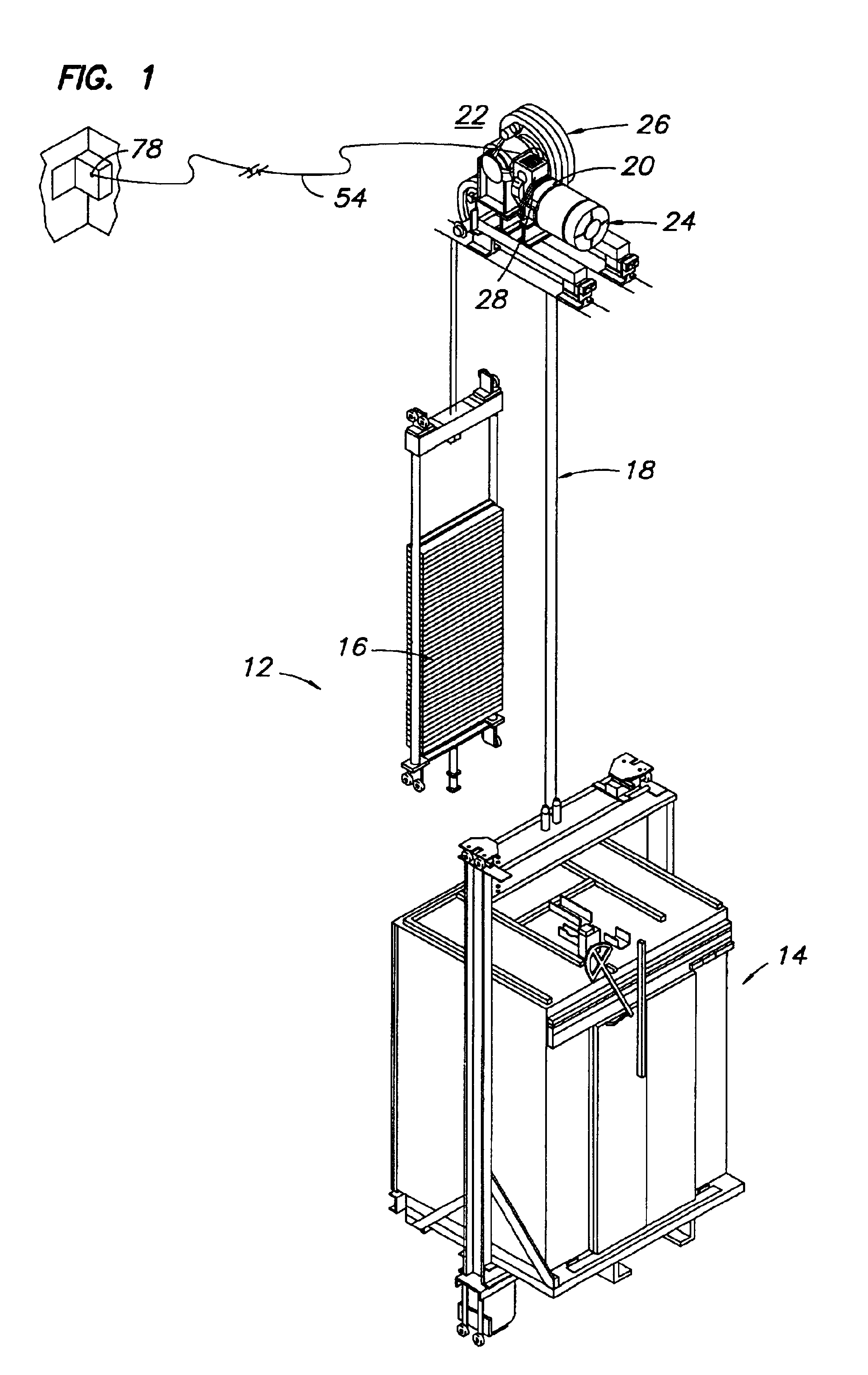

[0012]Illustrated in FIG. 1 is an elevator system 12 having a car 14, a counterweight 16, a plurality of ropes 18 interconnecting the car 14 and counterweight 16, and a traction machine 20 disposed in the overhead space 22 of the elevator system 12. The overhead space 22 is defined as the space between the top of the car 14 and the top of the hoistway with the car 14 at its highest position. Placing the traction machine 20 in this location permits the elimination of a separate machine-room.

[0013]The traction machine 20 includes a motor 24, traction sheave 26 and a brake assembly 28. The motor 24 drives the traction sheave 26, which is engaged with the ropes 18 to move the car 14 and counterweight 16 through the hoistway. The brake assembly 28 is engaged with an output shaft 30 of the motor 24 to hold the traction sheave 26 against movement when the car 14 is stopped.

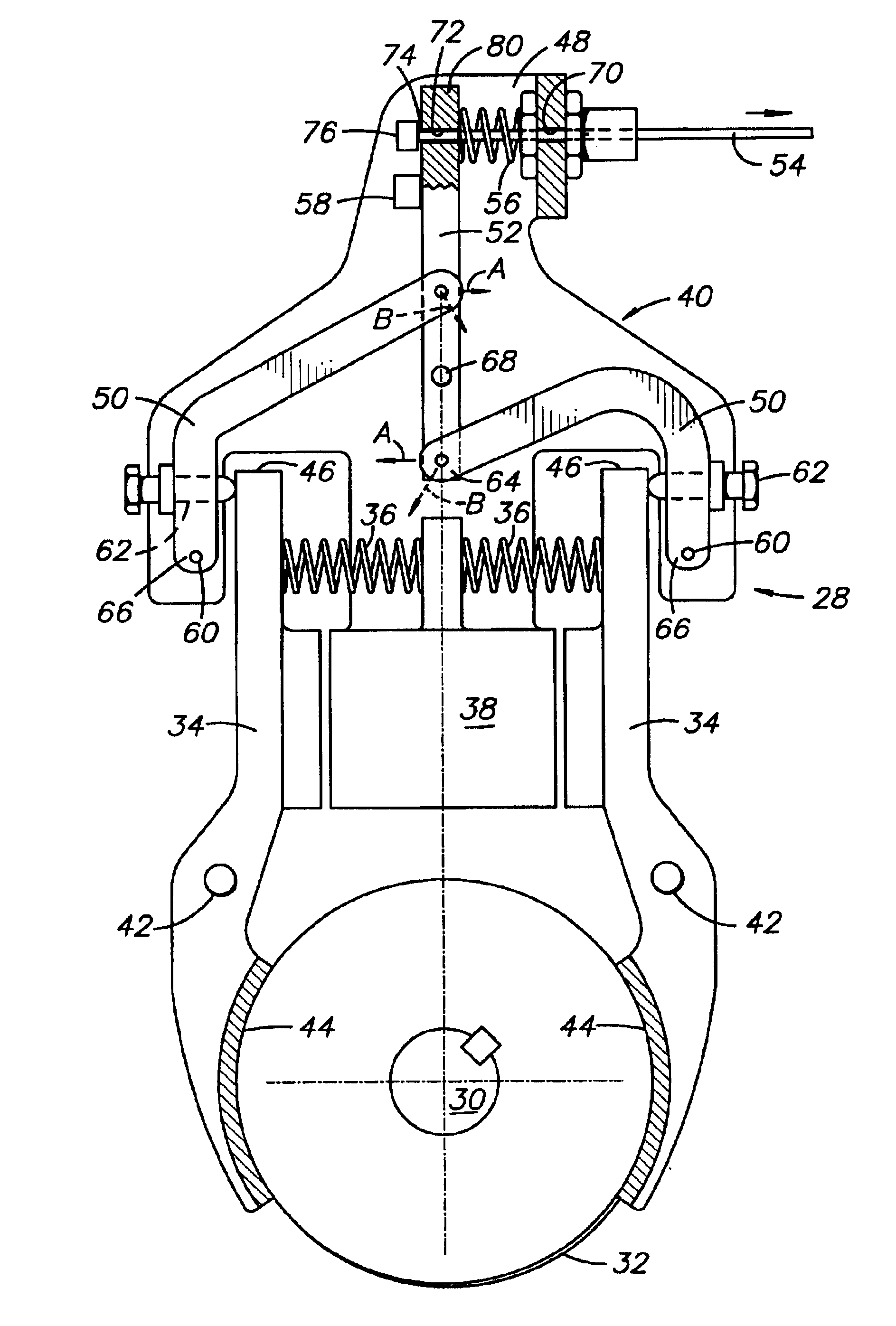

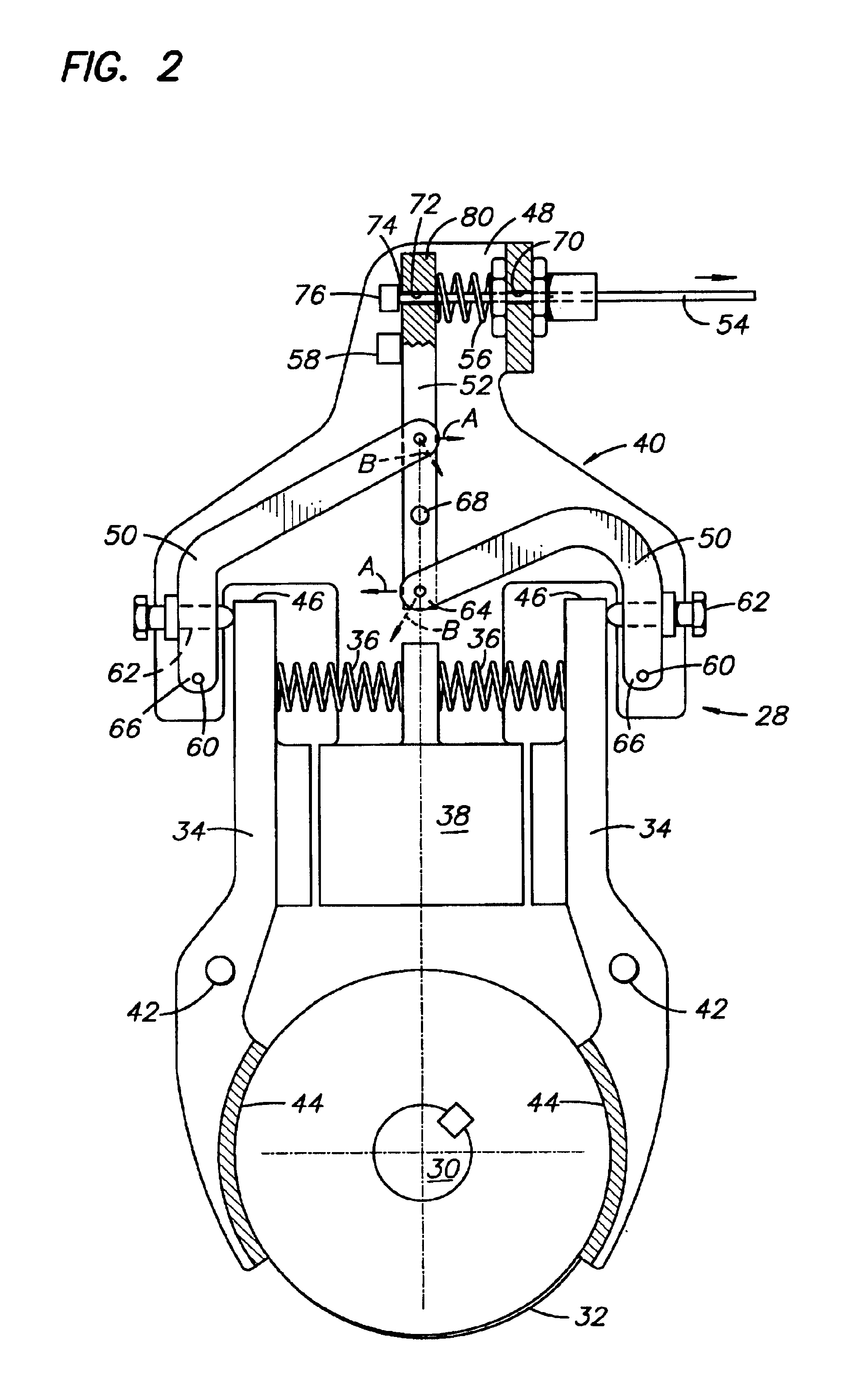

[0014]The brake assembly 28 is illustrated in more detail in FIG. 2. The brake assembly 28 includes a brake drum 32 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com