Reinforced composite structure

a composite structure and reinforced technology, applied in the direction of prosthesis, blood vessels, knitting, etc., can solve the problems of limiting the use of the trunk, applicants are not aware of any of the services and applicants are not aware of the use of pressurized tank structures. achieve the effect of light weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

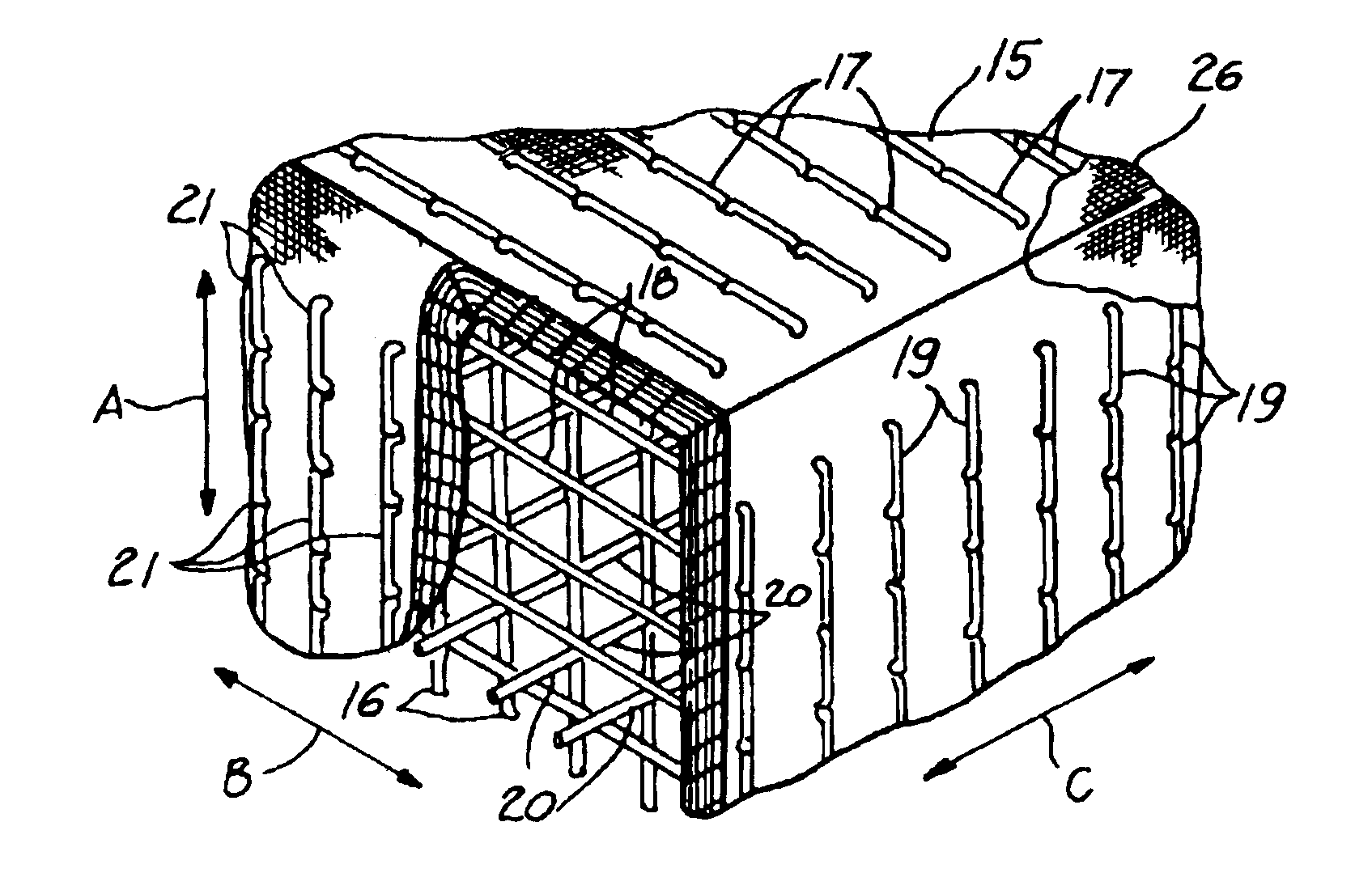

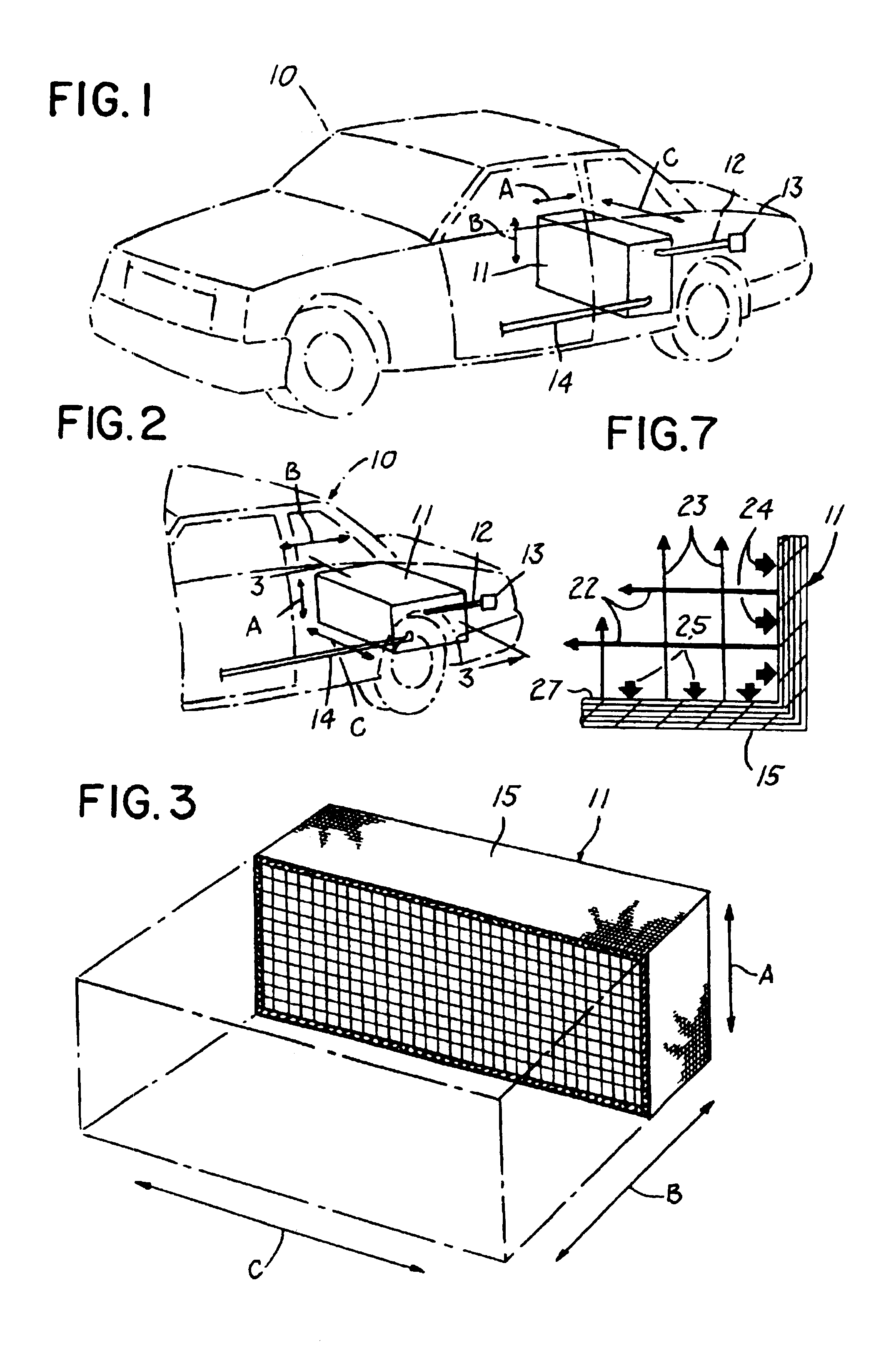

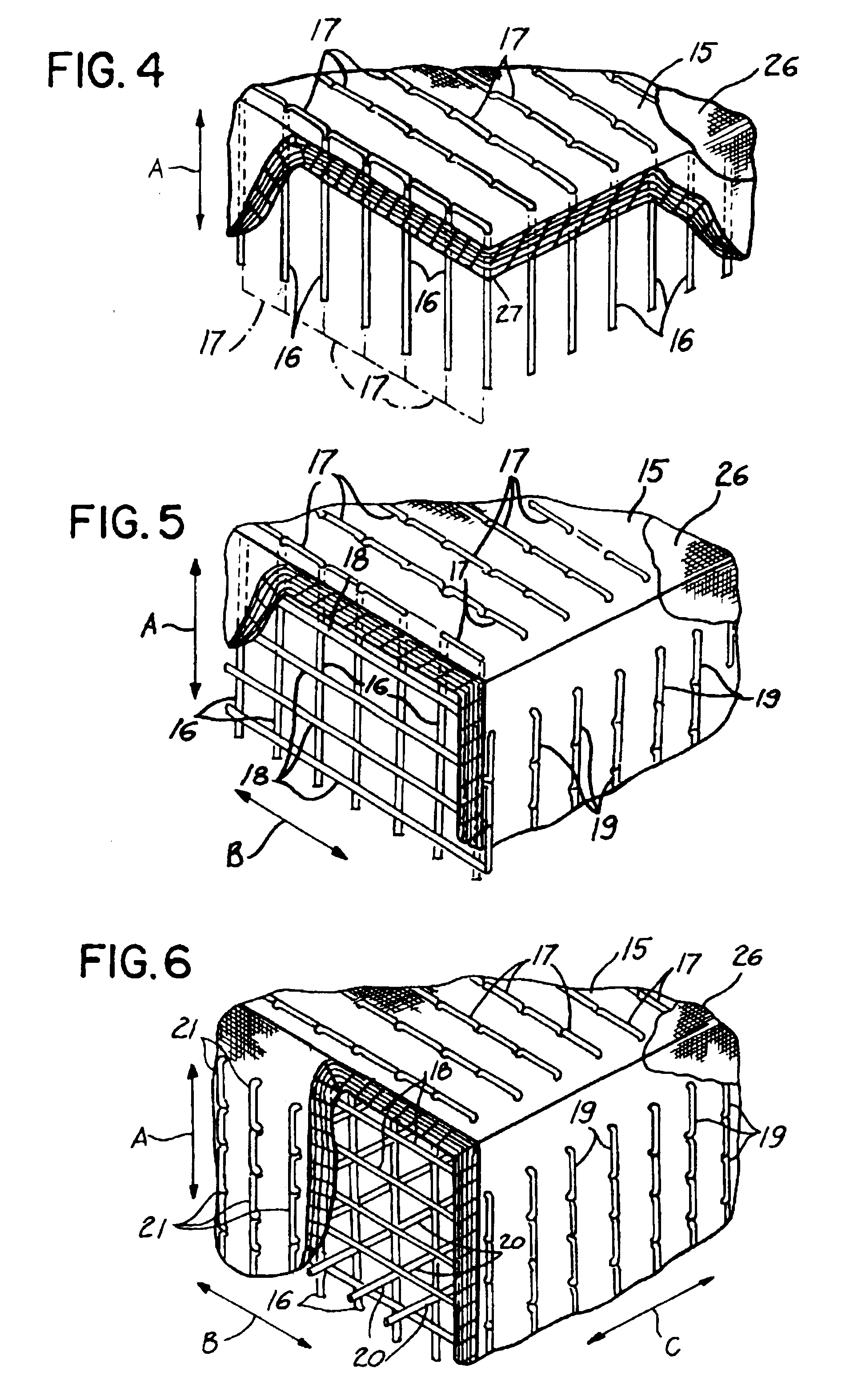

[0044]First, a core was formed from a piece of one inch thick foam cut into a six inch by six inch square. The edges of the form were rounded, using a one-half inch router bit, thereby creating a foam square with smooth semicircular edges having a one-half inch radius and two opposed five inch by five inch surfaces Notches were cut at the center of two opposed curved edges to receive metal inserts. The metal inserts were made from a two inch long, one inch diameter piece of aluminum rod that was sawed in half longitudinally to create an insert with a semicircular cross-section. A longitudinal center hole was drilled through the metal inserts, and the holes were tapped to accept a ⅛ pipe. The meal inserts were then inserted into the notches so that their ends were flush with the surface of the curved edge.

[0045]Next, three piles of three ounce per square yard E-glass woven fabric were wrapped around the core, followed by three plies of twenty ounce E-glass woven fabric. The second se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angles | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com