Modular sleeve

a module and sleeve technology, applied in the field of modular sleeves, can solve the problems of reducing the service life of the gun barrel, the inability to adapt to the rigid environment of laser operations, and the inability to quickly destroy lasers and ancillary optics and electronics, so as to facilitate internal fastening, reduce the size, and eliminate the effect of exposed cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

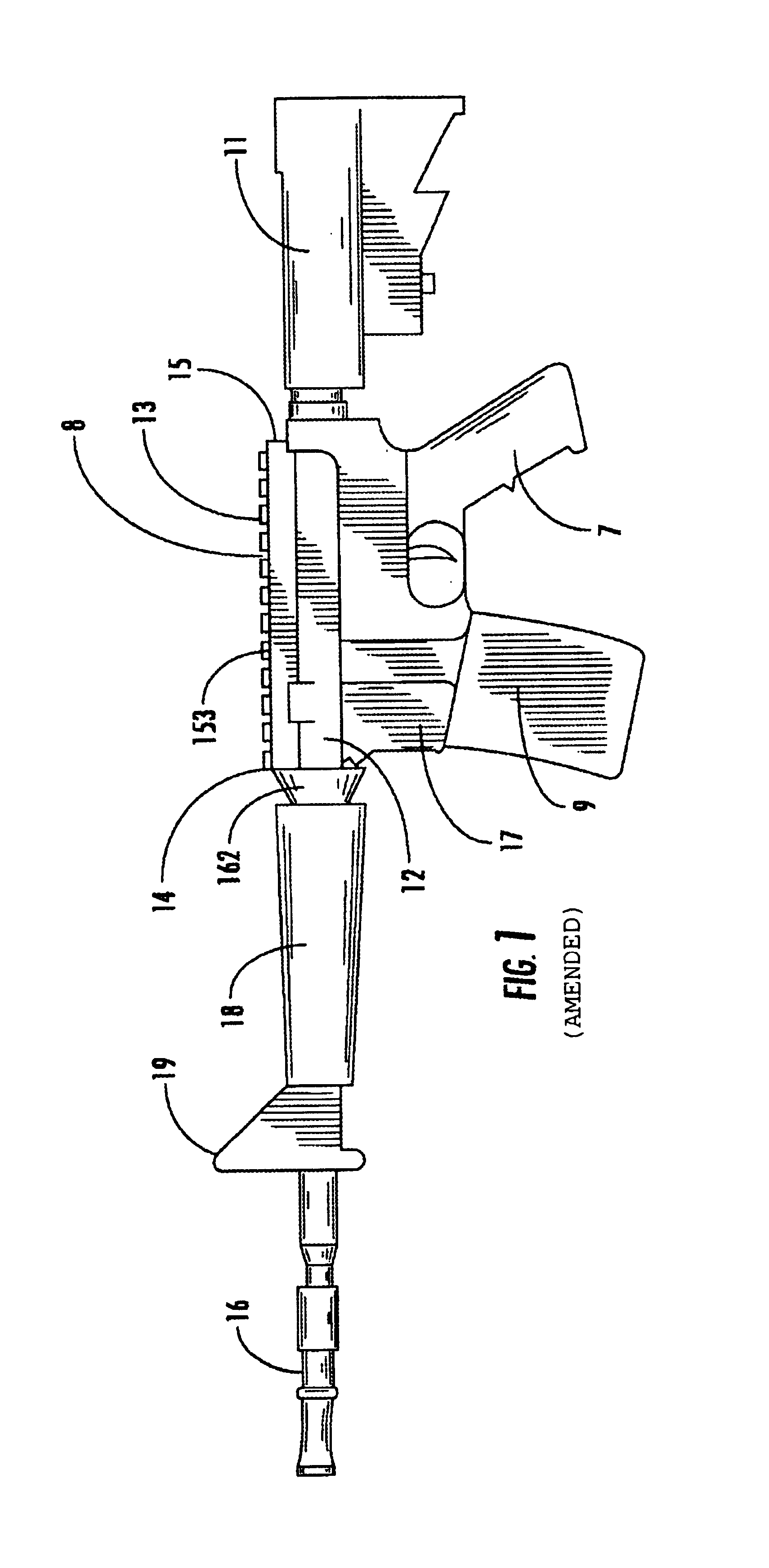

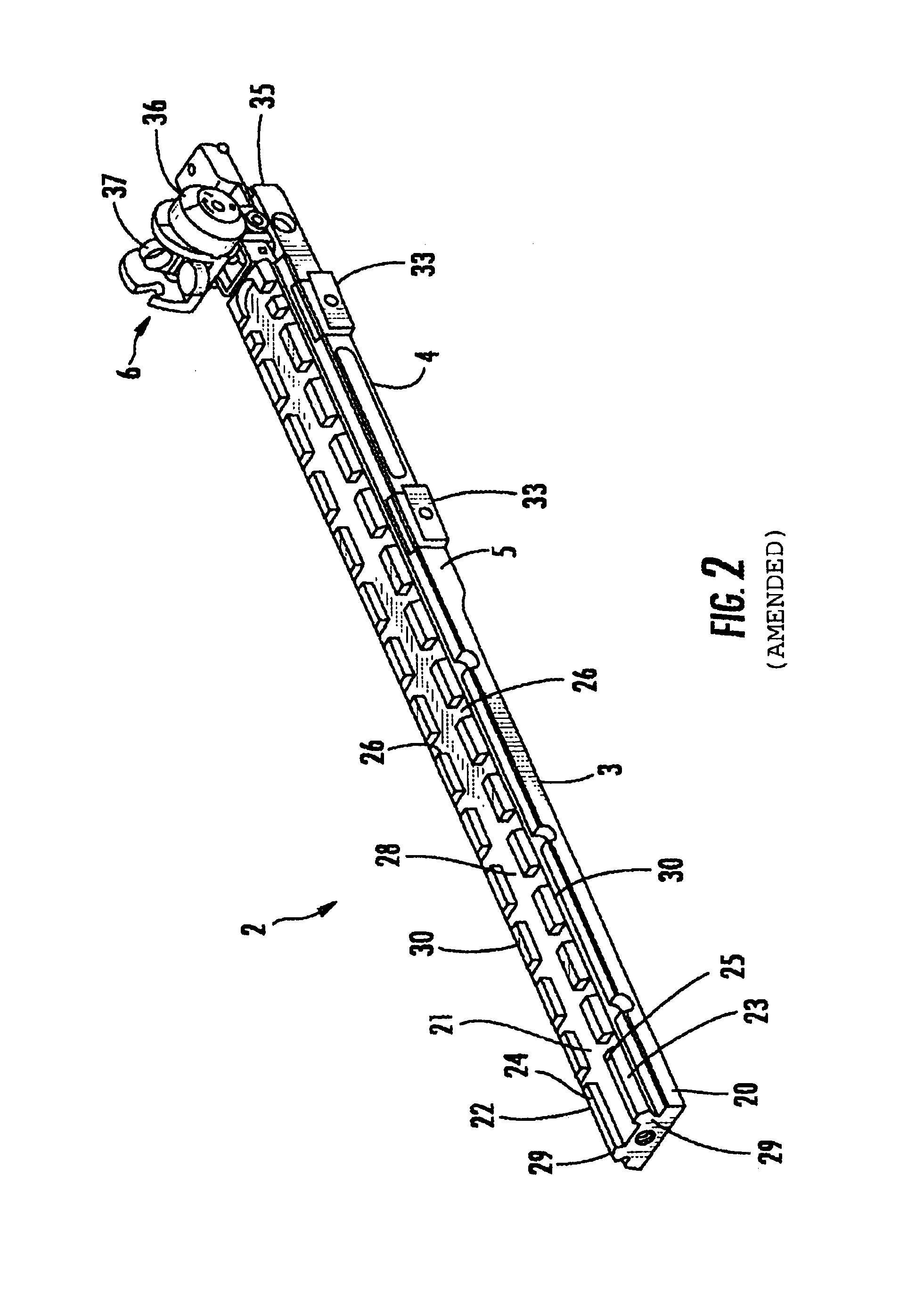

[0033]Referring to the drawings in detail wherein like elements are indicated by like numerals, there is shown in FIG. 1 an outline of a conventional combat firearm 10 having a conventional stock 11, upper receiver 12 with flat top 13, lower receiver 17, barrel 16, pistol grip 7, and magazine 9. The barrel 16 is joined to the upper receiver 12. The barrel 16 defines the forward portion of the firearm 10 and the stock 11 defines the rearward portion of the firearm 10. The longitudinal axis of the firearm 10 runs from stock 11 through receiver 12, 17 to barrel 16. The barrel 16 is joined to the forward portion 14 of the upper receiver 12, i.e., the upper receiver 12“receives” the barrel 16. The stock 11 is joined to the rear portion 15 of the upper receiver 12. The barrel 16 has protective handguards 18 about its circumference.

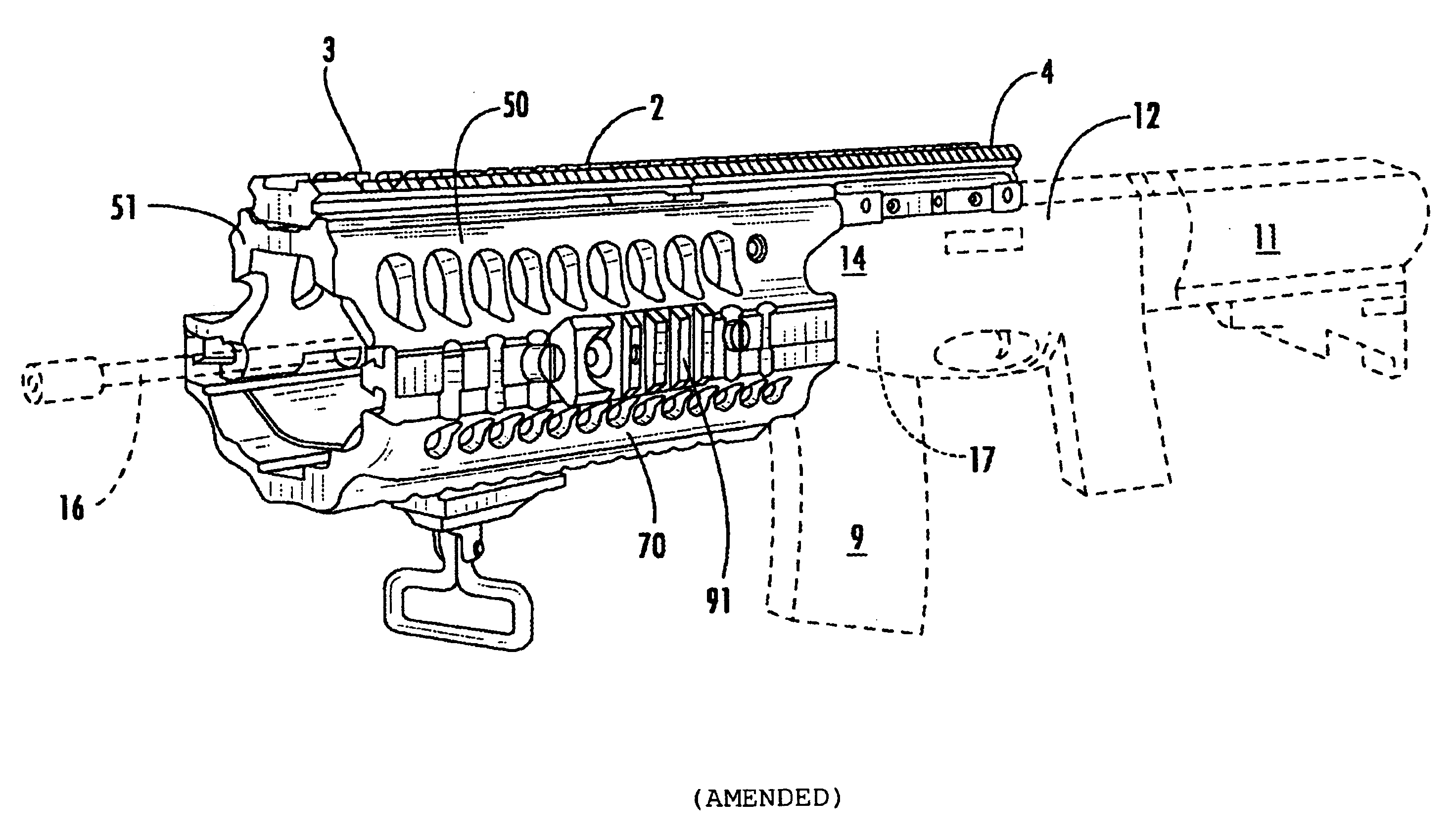

[0034]The present invention provides a modular sleeve 1 about the firearm barrel 16 replacing the firearm's conventional handguards with a handguard assembly in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com