Pulsed flow for capacity control

a technology of capacity control and pulse flow, which is applied in the direction of positive displacement liquid engines, subcoolers, light and heating apparatus, etc., can solve the problems of expensive motor driven modulation valves or only the control of steps, and achieve the effect of less expensiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

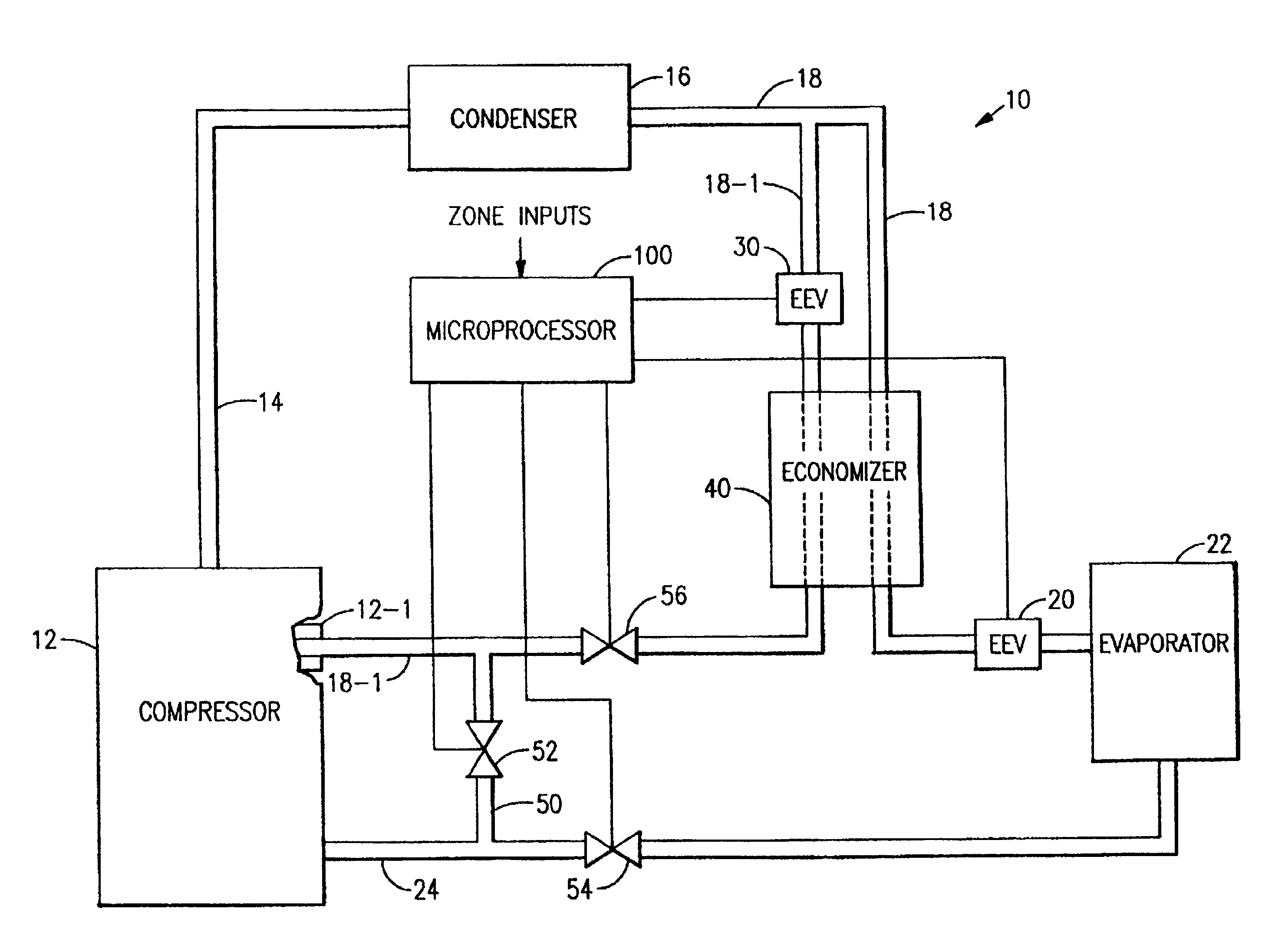

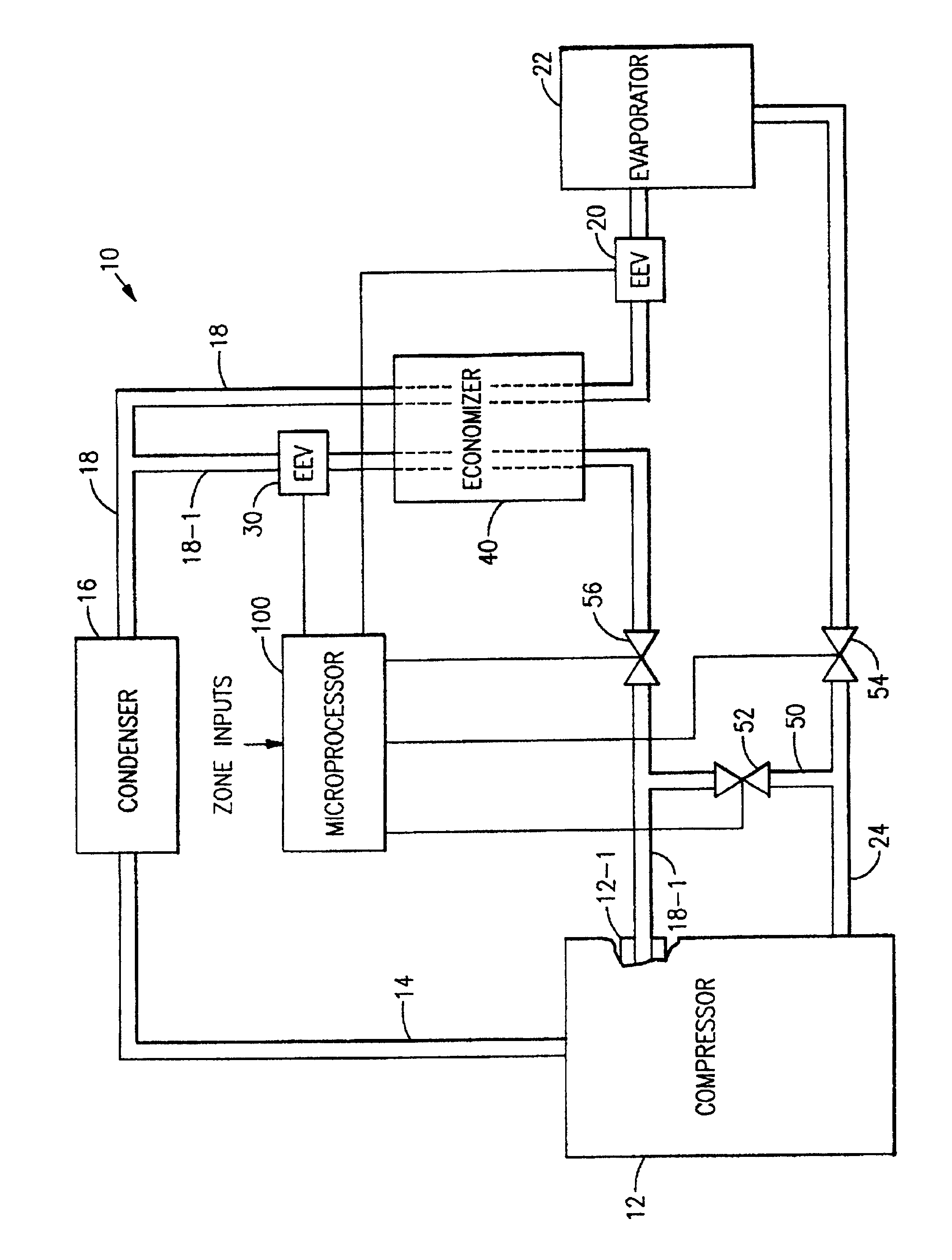

[0010]In the FIGURE, the numeral 12 generally designates a hermetic compressor in a closed refrigeration or air conditioning system 10. Starting with compressor 12, the system 10 serially includes discharge line 14, condenser 16, line 18, expansion device 20, evaporator 22, and suction line 24 completing the circuit. Line 18-1 branches off from line 18 and contains expansion device 30 and connects with compressor 12 via port 12-1 at a location corresponding to an intermediate point in the compression process. Economizer heat exchanger 40 is located such that line 18-1, downstream of expansion device 30, and line 18, upstream of expansion device 20, are in heat exchange relationship. The expansion devices 20 and 30 are labeled as electronic expansion devices, EEV, and are illustrated as connected to microprocessor 100. In the case of expansion device 20, at least, it need not be an EEV and might, for example, be a thermal expansion device, TEV. What has been described so far is gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com