Ultrabarrier substrates

a technology of substrates and substrates, applied in the field of substrate coatings, can solve the problems of deterioration or rendering products useless, orders of magnitude below what is required, and poor gas and liquid permeation resistance of plastics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

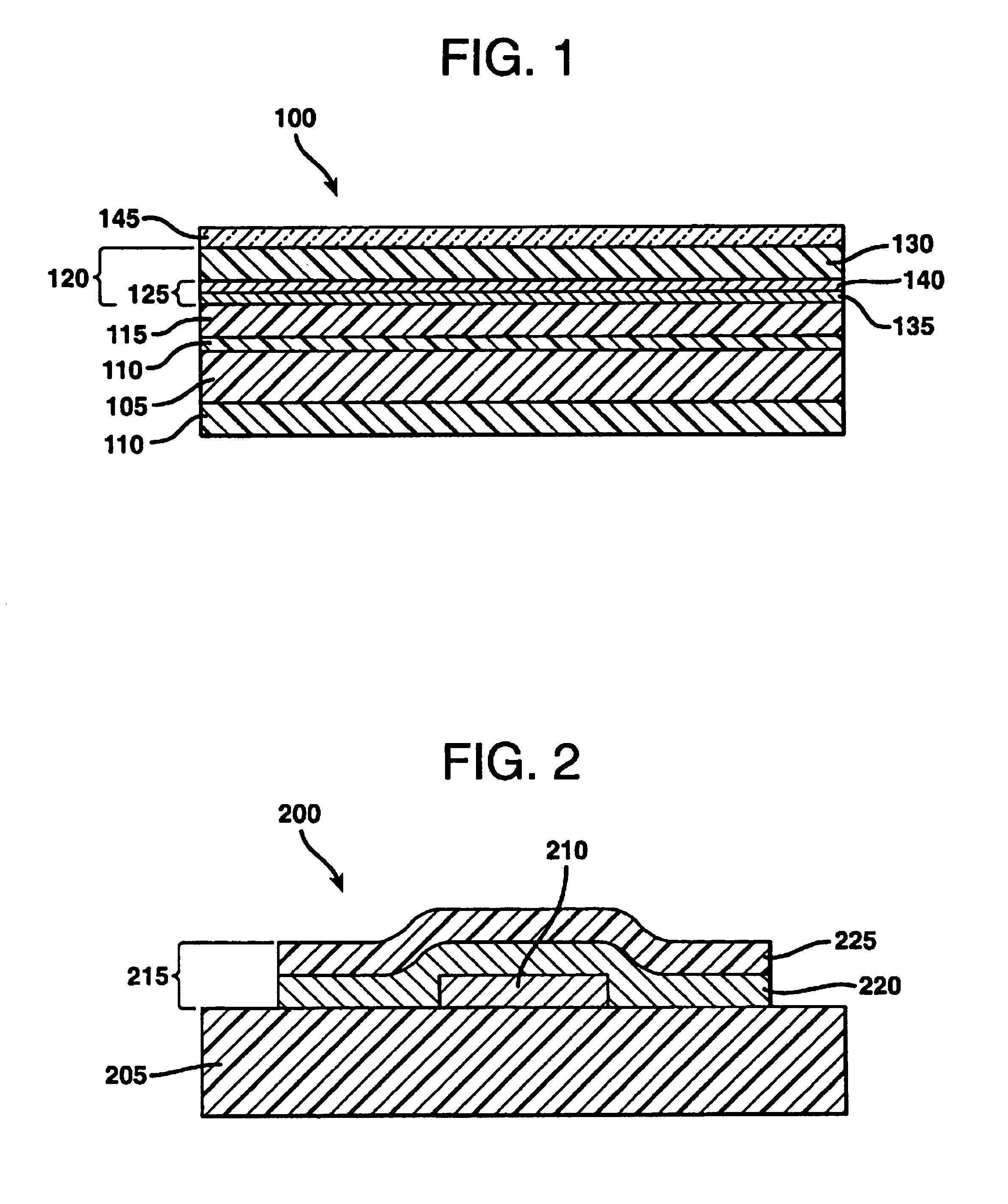

[0019]One embodiment of the barrier assembly of the present invention is shown in FIG. 1. The barrier assembly is supported by a substrate 105. The substrate 105 can be either rigid or flexible. A flexible substrate can be any flexible material, including, but not limited to: polymers, for example, polyethylene terephthalate (PET), polyethylene naphthalate (PEN), or high temperature polymers, such as polyether sulfone (PES), polyimides, or Transphan™ (a high glass transition temperature cyclic olefin polymer available from Lofo High Tech Film, GMBH or Weil am Rhein, Germany); metal; paper; fabric; and combinations thereof. Rigid substrates are preferably glass, metal, or silicon.

[0020]There are scratch resistant layers 110 on either side of the substrate 105 to protect it. When a scratch resistant layer is included, it is preferred that both sides of the substrate have a scratch resistant layer. This helps to balance stresses and prevent deformation of a flexible substrate during pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| oxygen transmission rate | aaaaa | aaaaa |

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com