Master cylinder

a master cylinder and cylinder head technology, applied in the field of master cylinders, can solve the problems of high flow, insufficient inability to achieve sufficient flow rate of brake fluid, so as to shorten the ineffective stroke, promote the effect of fast fill function and no fluid flow resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

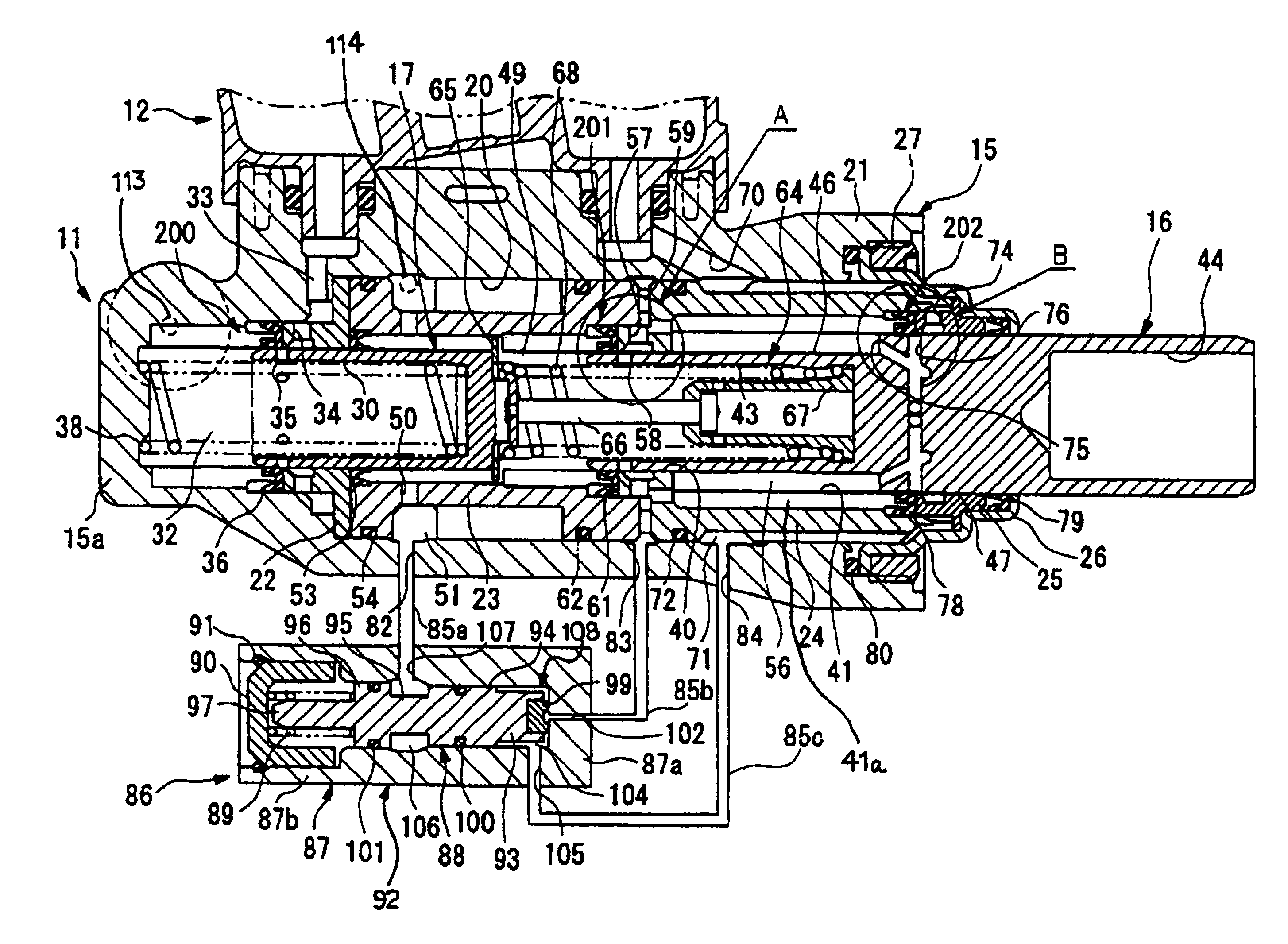

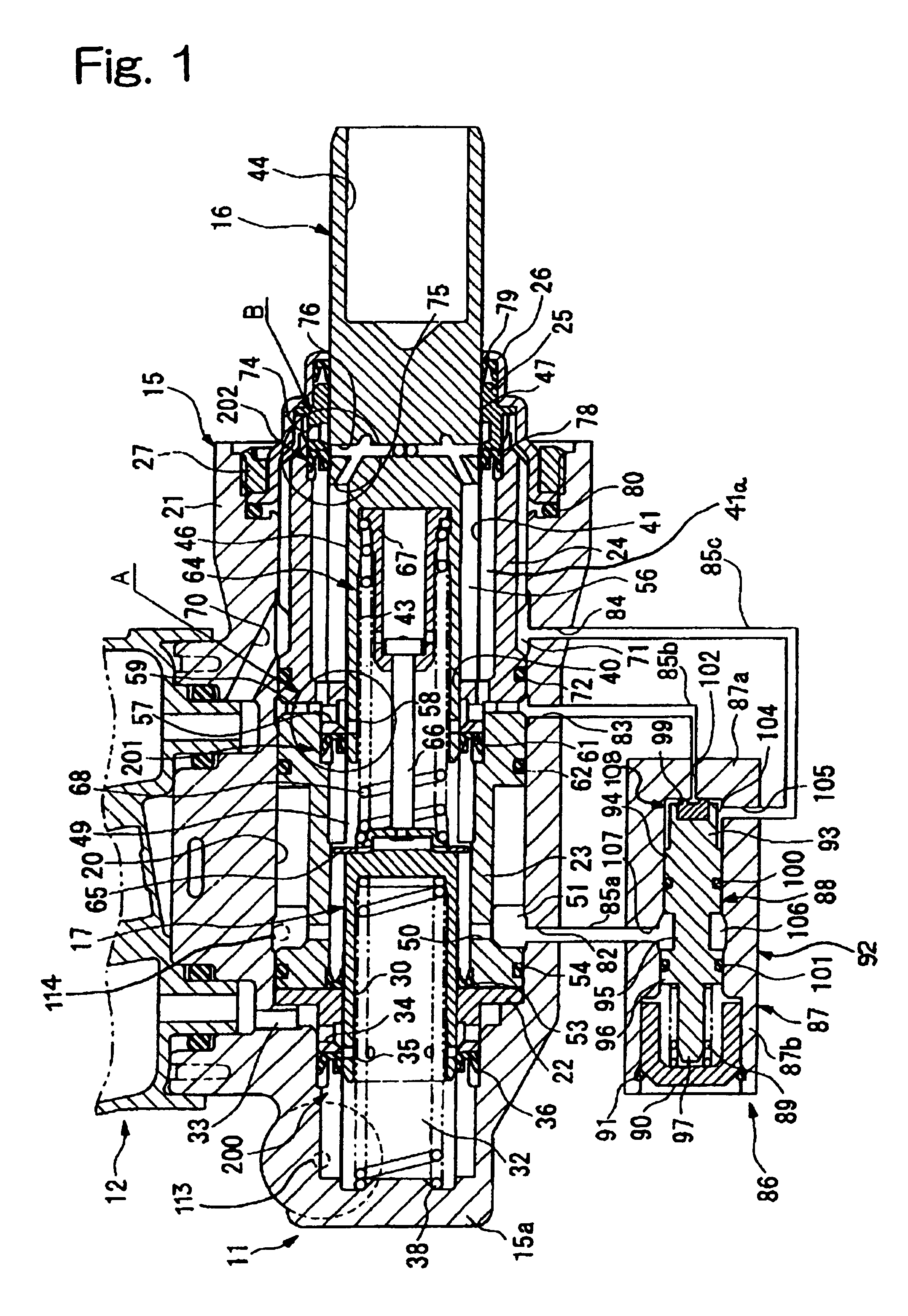

[0042]An explanation will be given of a master cylinder according to the invention in reference to FIG. 1 through FIG. 10.

[0043]FIG. 1 shows the master cylinder of the first embodiment and here, notation 11 designates a master cylinder main body for generating a brake hydraulic pressure in accordance with an input of a brake pedal introduced via a booster (not shown), and notation 12 designates a reservoir attached to an upper portion of the master cylinder main body 11 for storing a brake fluid which is charged to and discharged from the master cylinder main body 11.

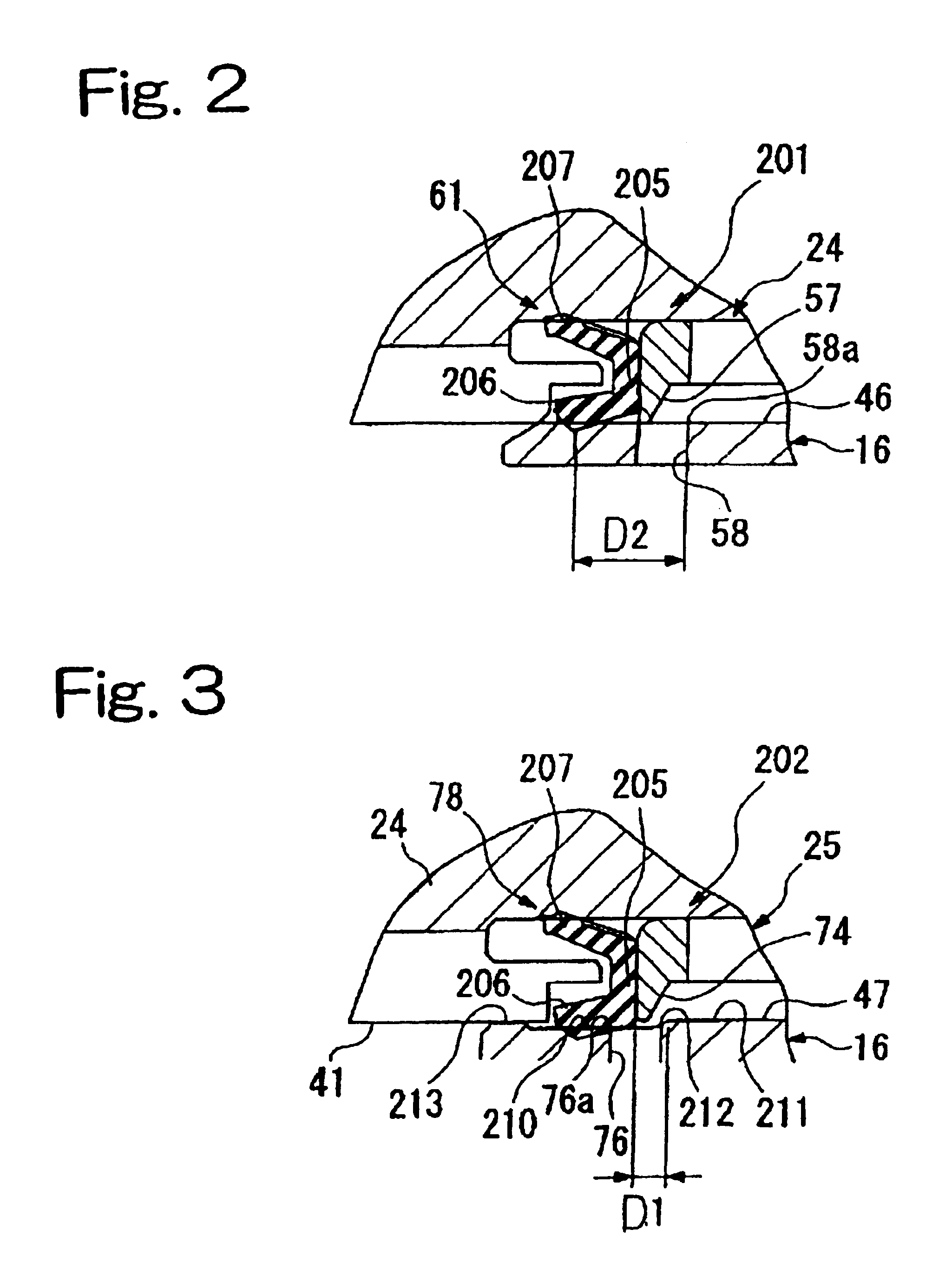

[0044]The master cylinder main body 11 is provided with a stepped cylinder 15 having a shape of a substantially bottomed cylinder along a horizontal direction, a primary piston (stepped piston) 16 slidably fitted to portion (right side in FIG. 1) of the stepped cylinder 15, and a secondary piston 17 slidably fitted to the stepped cylinder 15 closer to a bottom portion 15a side (left side in FIG. 1), which is described l...

second embodiment

[0121]Further, the lid member 90 of the control valve 86 is screwed to the valve cylinder main body 87 and an O-ring (ring seal) 111 is provided therebetween for sealing a clearance therebetween. Thereby, an interval between the valve cylinder 92 and a side of the valve piston 88 opposed to the fluid chamber 104, constitutes a damper chamber 112 arranged with the valve spring 89 and operated with the hydraulic pressure. The damper chamber 112 communicates with the fluid chamber 104 via the throttle path 110 (in other words, the other end side of the throttle path 110 opposed to the fluid chamber 104, is opened to the damper chamber 112).

[0122]Next, an explanation will be given of operation of the master cylinder according to above-described second embodiment.

[0123]When the primary piston 16 is pressed toward the bottom portion 15a by the rod of the booster connected to the brake pedal, the large diameter pressurizing chamber 56 and the primary side small diameter hydraulic chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com