Fractal device for mixing and reactor applications

a technology of fractal devices and reactors, applied in indirect heat exchangers, lighting and heating apparatuses, transportation and packaging, etc., can solve the problems of energy waste, and achieve the effect of eliminating large-scale eddies, reducing the yield of chemical reactions, and avoiding large-scale mixing inhomogeneities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

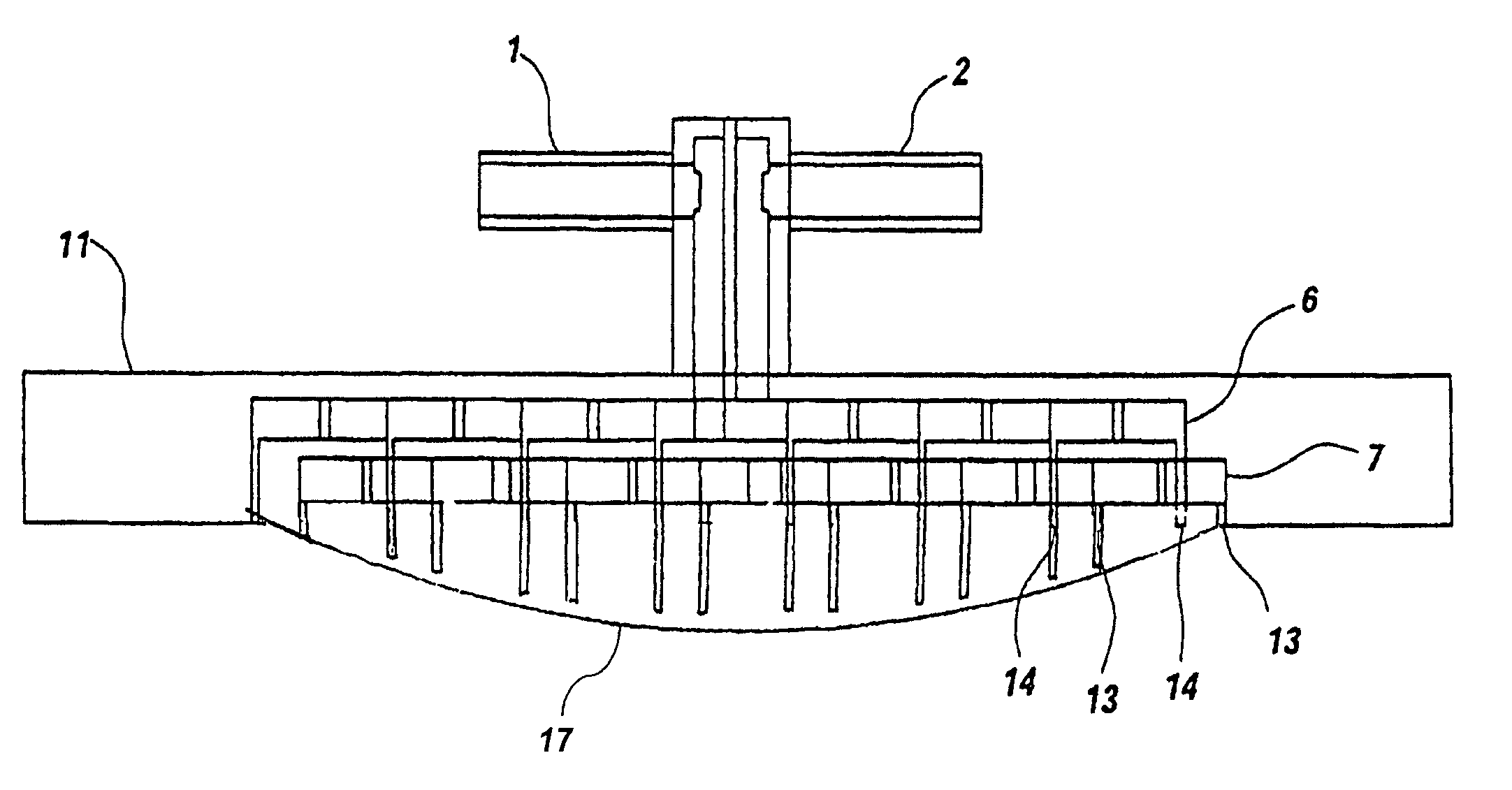

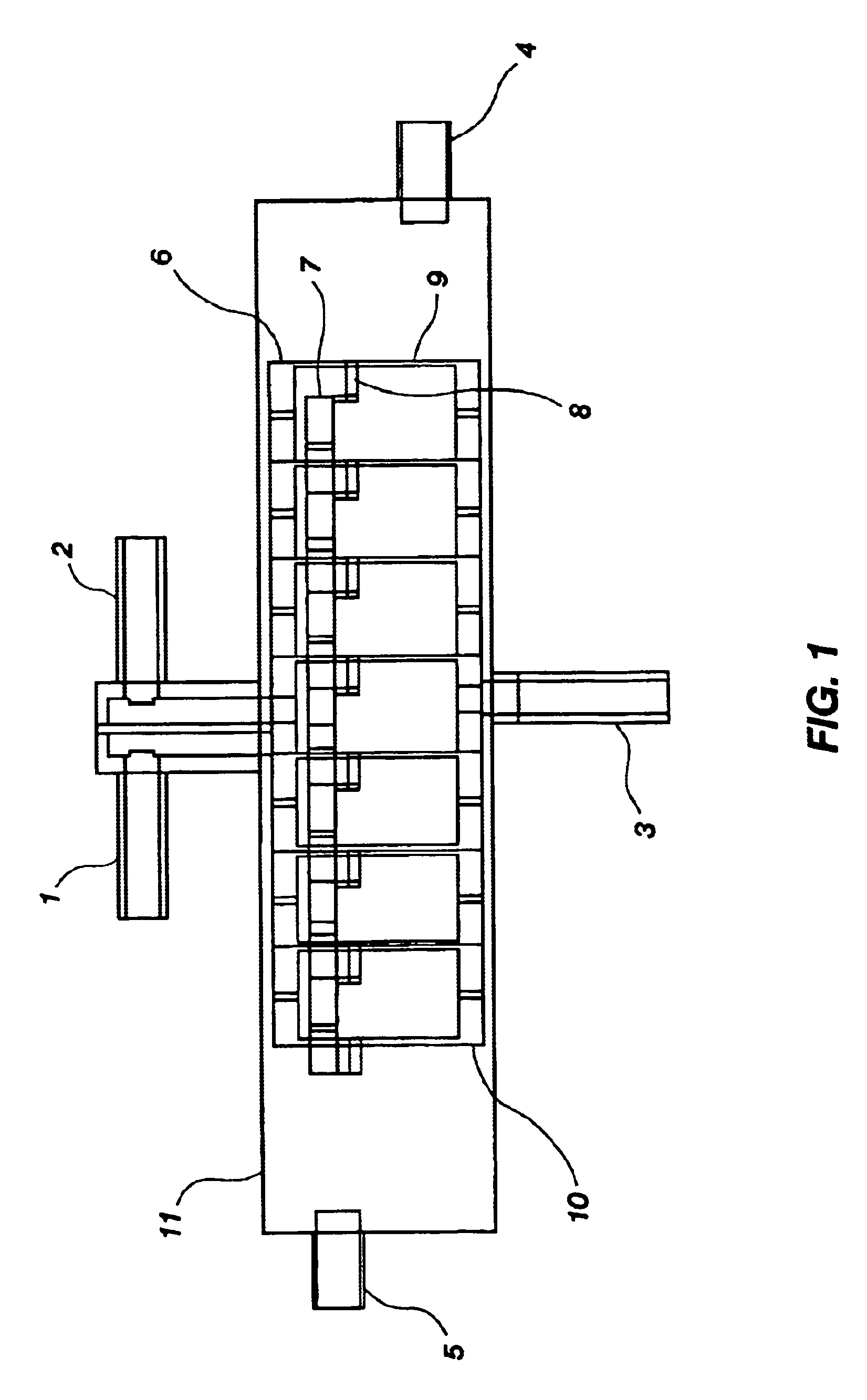

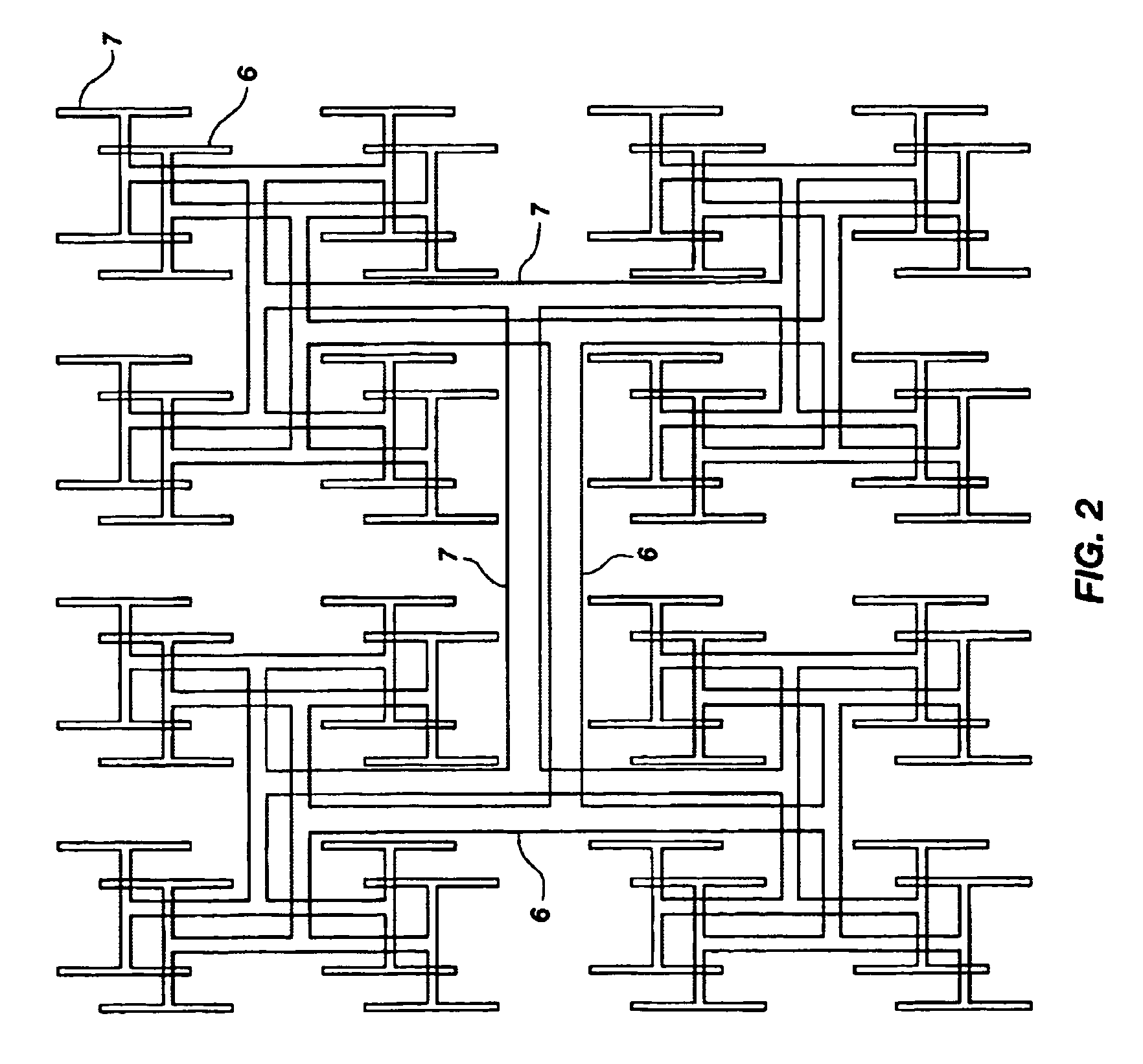

[0043]FIG. 1 illustrates an embodiment of a fractal structure which in addition to the offset fractal characteristic of this invention also includes merging and contact channels, a fractal collector and a heat exchange enclosure. This embodiment is useful as a processing (mixing and / or reaction element in pipe configurations. Flow input channels 1 and 2 are for the separate fluids which will be mixed. Additional inputs can be added if more than two fluids are to be mixed. Input 1 provides flow to offset fractal distributor 7 while input 2 provides flow to offset fractal distributor 6. The fluid flows are scaled and distributed through these offset fractals.

[0044]After independent fractal scaling of the fluids, the two input Lows contact one merging channels 8 and proceed in a mixed condition through channels 9. In the channels 9, hereinafter denominated “contact channels,” the fluids are finally brought into contact one with another. The flows in contact channels 9 are re-scaled to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com