Apparatus and method for producing foaming concrete construction wall plate coated by glass fiber reinforced cement

A technology for enhancing cement and production equipment, applied in the light field of GRC construction where it is applicable, it can solve the problems of poor environmental adaptability, low construction efficiency, wall cracking, etc., and achieve highly flexible production performance, strong assembly and matching ability, Reduce the effect of secondary processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

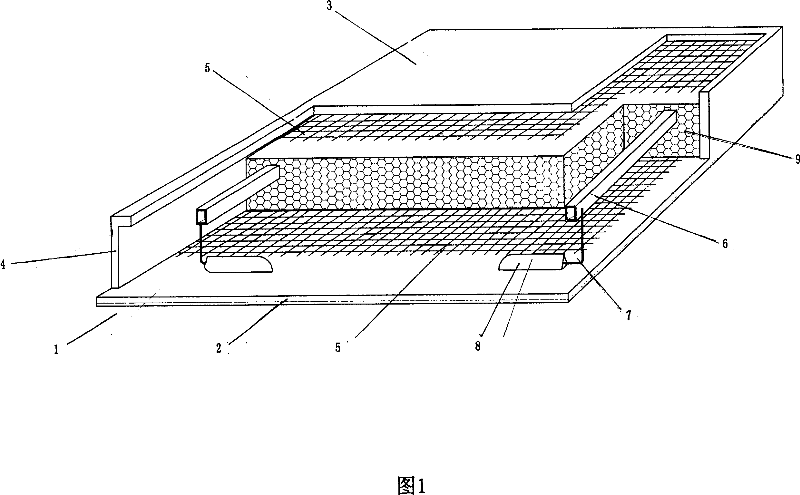

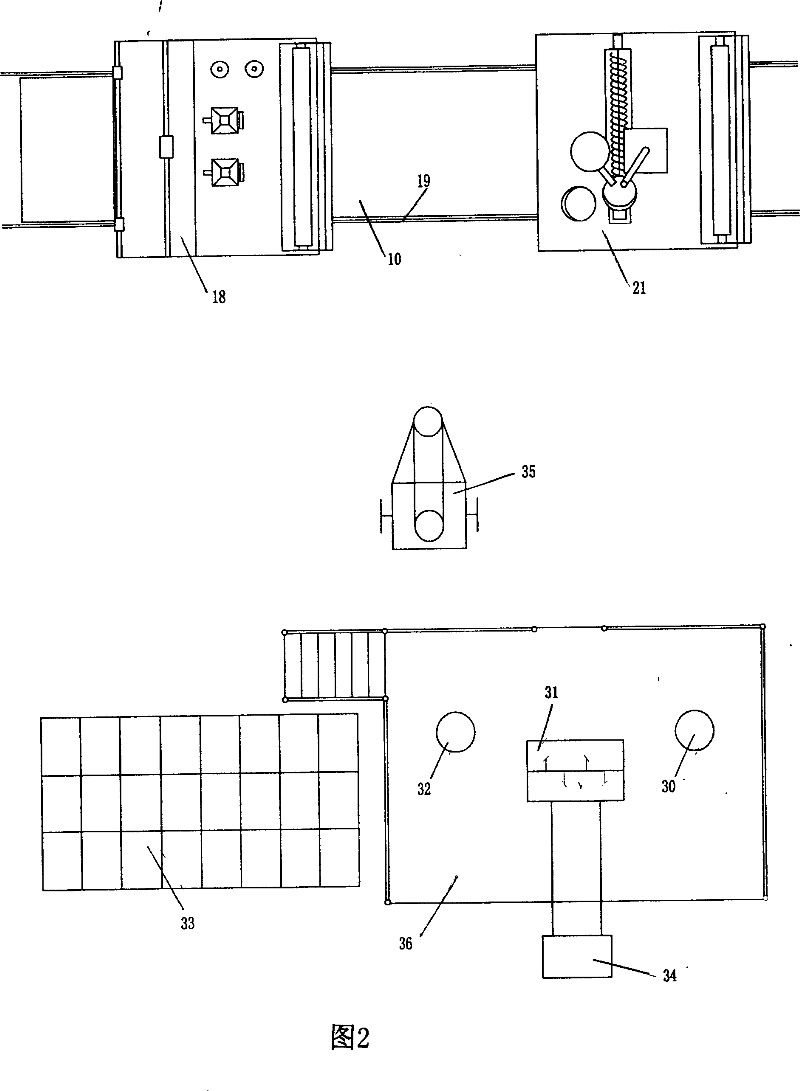

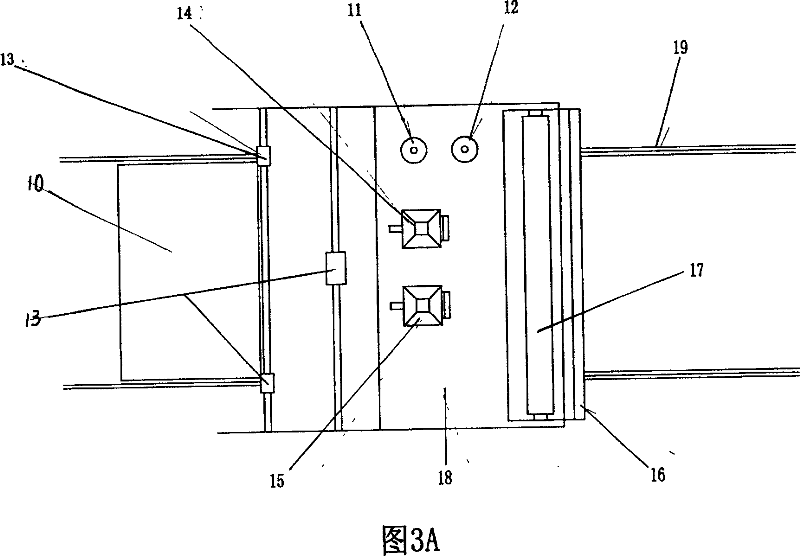

[0038] Referring to accompanying drawings 1 to 4, production equipment for glass fiber-reinforced cement-packed foamed concrete building wall panels:

[0039] The glass fiber reinforced cement package foam concrete building wallboard 1, including the relative GRC surface layer 2 of glass fiber reinforced cement, the back layer 3, and the side layer 4 connecting the surface layer and the back layer, constituted glass fiber reinforced cement The outer surface layer of the foamed concrete building wallboard is tightly attached to the inner side of the outer surface layer. The inner structure of the glass fiber reinforced cement wrapped foamed concrete building wallboard includes a steel support frame 6 and a steel support frame connected to The steel anchor bolt 7 and the steel anchor bolt 7 of the GRC surface layer are connected with the glass fiber reinforced cement surface layer by glass fiber reinforced cement ash cake 8, and the foamed concrete 9 is filled in the outer surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com