Linear combined grinding machine

A straight line and grinding machine technology, applied in the field of automobile brake pads, can solve the problems of affecting production efficiency and increasing labor costs, and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

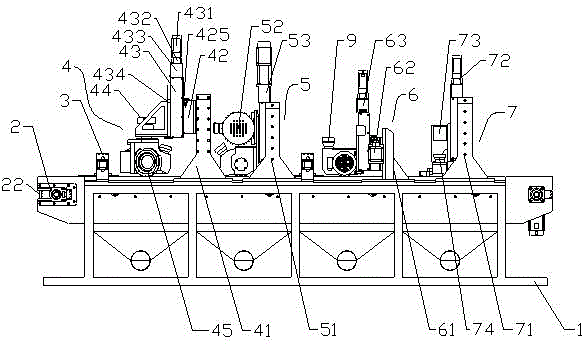

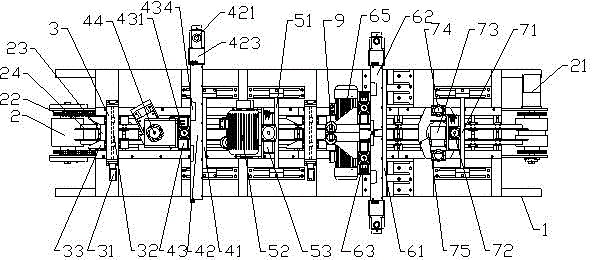

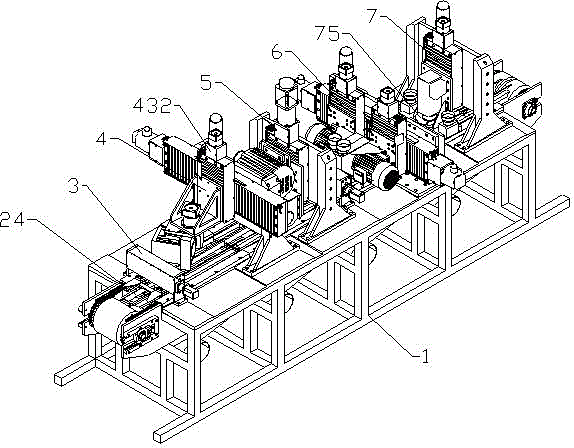

[0052] Accompanying drawing is the specific embodiment of the present invention. like Figure 1 to Figure 15 As shown, this kind of linear combination grinding machine includes a frame 1, on which a conveying device 2 is arranged, and on the frame 1 along the conveying direction of the conveying device 2, a slotting device 4, a rough grinding device 5, a grinding inclined The device 6, the fine grinding device 7, the front of the slotting device 4, the rough grinding device 5 and the oblique grinding device 6 are respectively provided with a guide device 3, wherein:

[0053] like Figure 9 As shown, the conveying device 2 includes a double-row sprocket 22 driven by the first servo motor 21. Several push plates 23 are arranged between the two sprockets on the double-row sprocket 22, and guide rails are also provided on the frame 1. 24. The guide rail 24 is located below between the two sprockets. An electromagnet 25 is provided under the guide rail 24. After the electromagnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com