Alpha type high-strength gypsum and its preparation method

A technology for high-strength gypsum and gypsum, which is applied in the field of gypsum materials and its preparation, can solve problems such as complicated processes, and achieve the effects of simple process, material saving and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

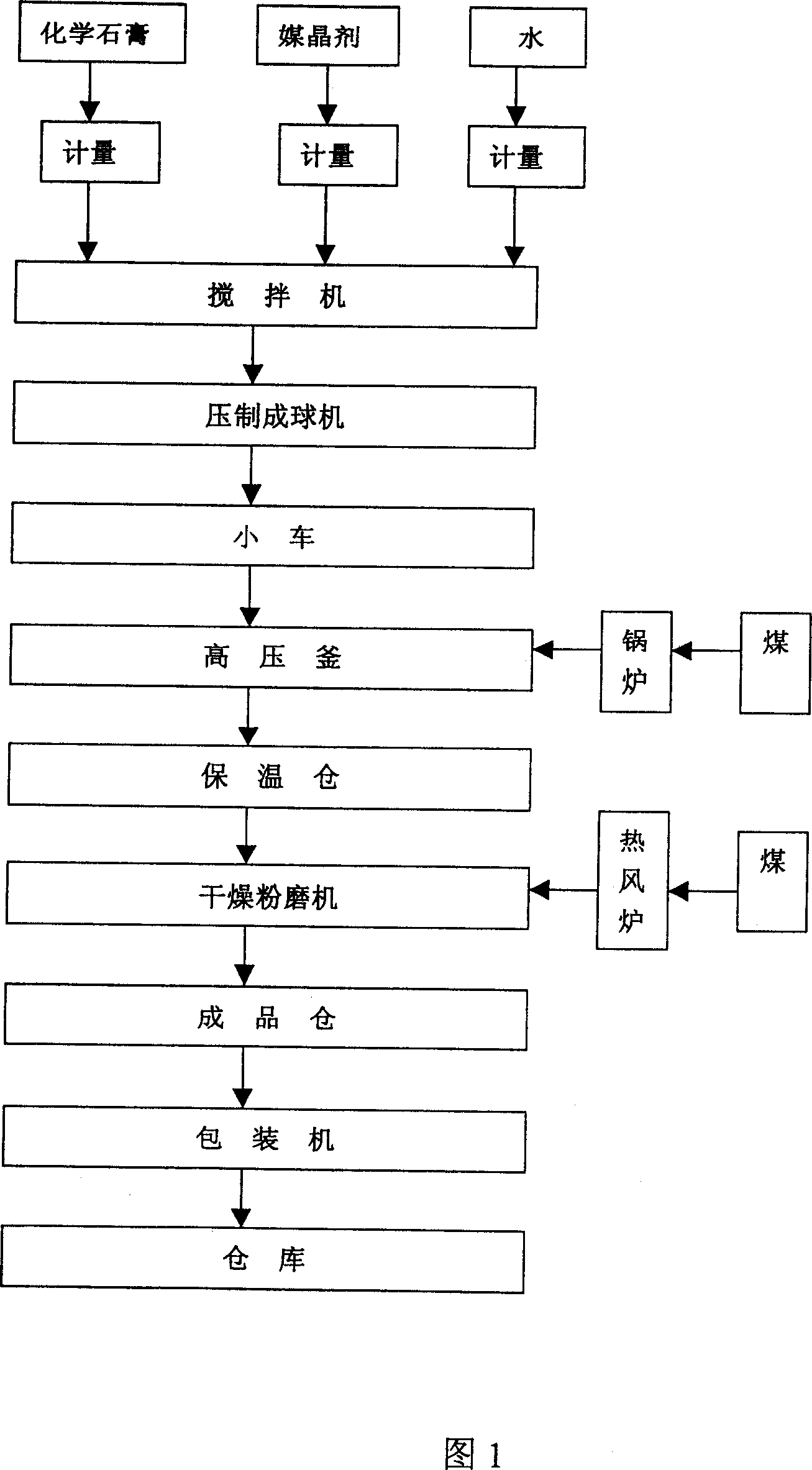

[0024] The following structural drawings and embodiments further illustrate the present invention.

[0025] As shown in Figure 1.

[0026] An α-type high-strength gypsum, which is α-type hemihydrate gypsum with a short columnar crystal shape and a dry compressive strength above 25Mpa, which is formed from chemical gypsum and a crystallization agent.

[0027] The concrete production process of above-mentioned gypsum is:

[0028] a. Stirring: mix the crystallization agent into the chemical gypsum at a ratio of 0.1-1%, add 10-15% water and stir evenly;

[0029] b. Compaction: mechanically press the uniformly stirred gypsum material into a spherical or block shape, so that the mediator and the gypsum crystals are evenly and closely contacted and adsorbed on the surface of the gypsum crystals;

[0030] c. Cooking: Put the above-mentioned spherical or massive dihydrate gypsum material obtained by mechanical pressing into an autoclave and autoclave for 1 to 3 hours under saturated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com