Concrete powring appts.

A pouring device and concrete technology, which is applied in shaft equipment, earthwork drilling, wellbore lining, etc., can solve the problems of damage, accelerated concrete falling speed, and low durability, and achieve the goals of preventing separation, reducing falling speed, and improving durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

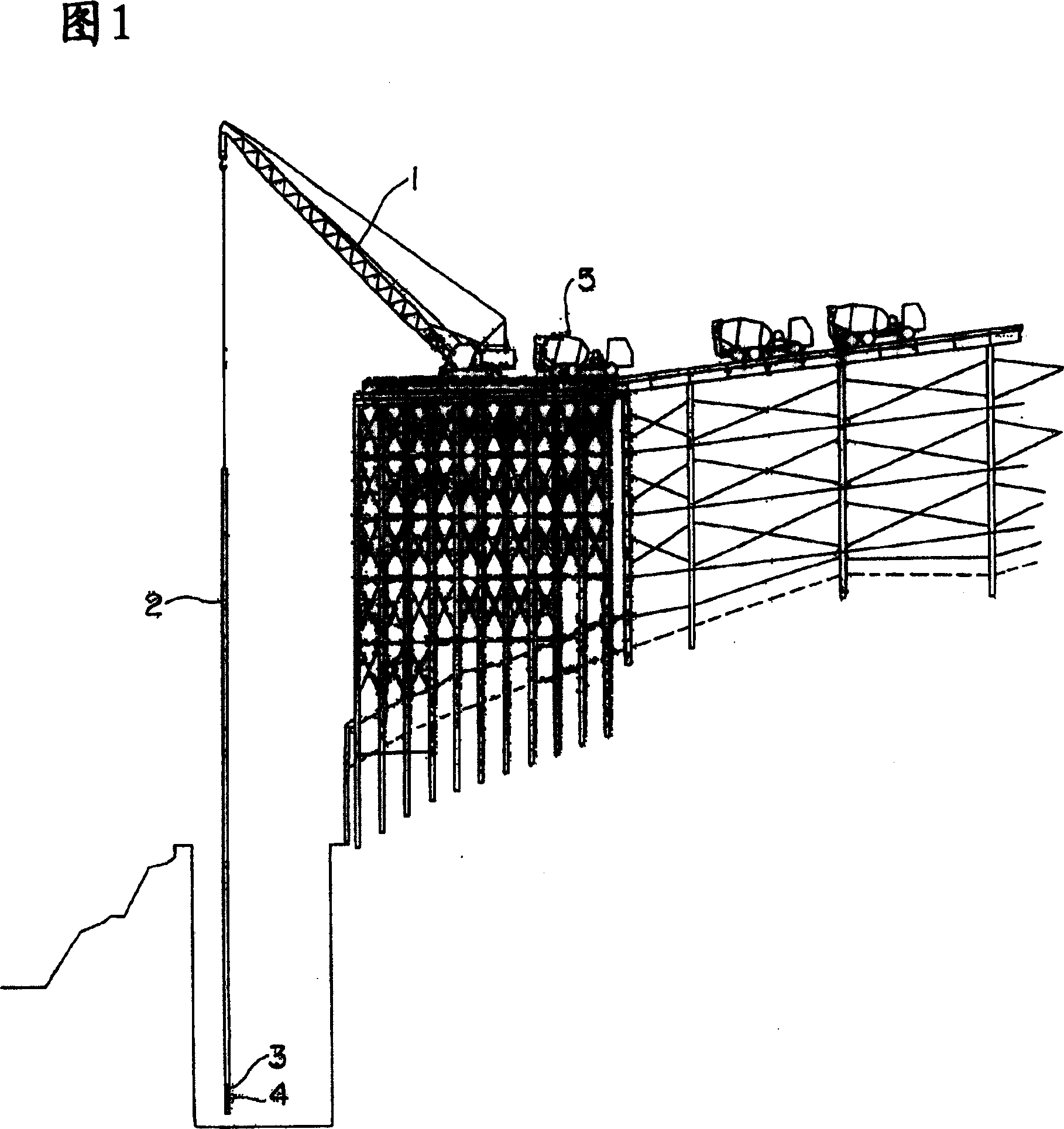

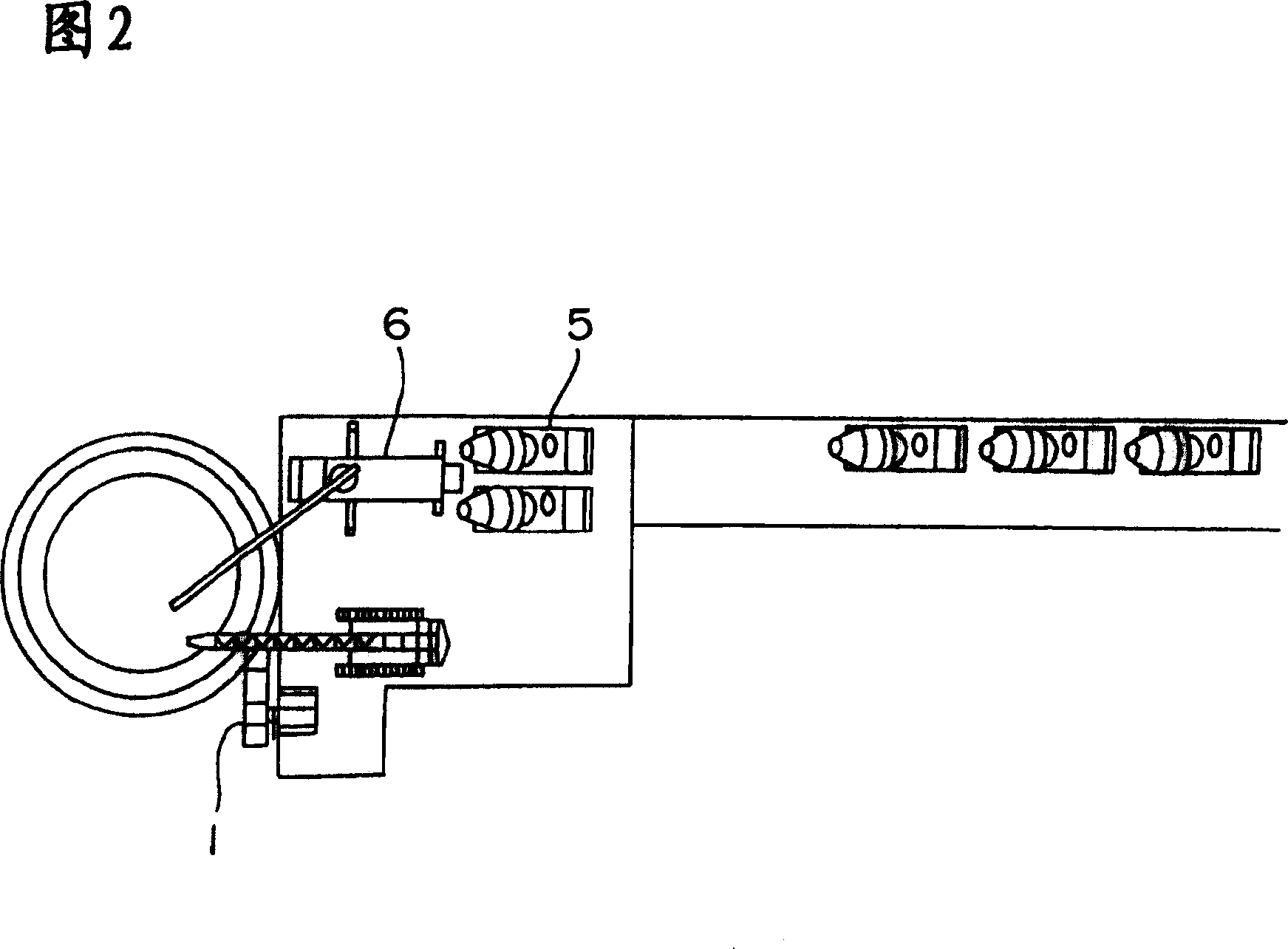

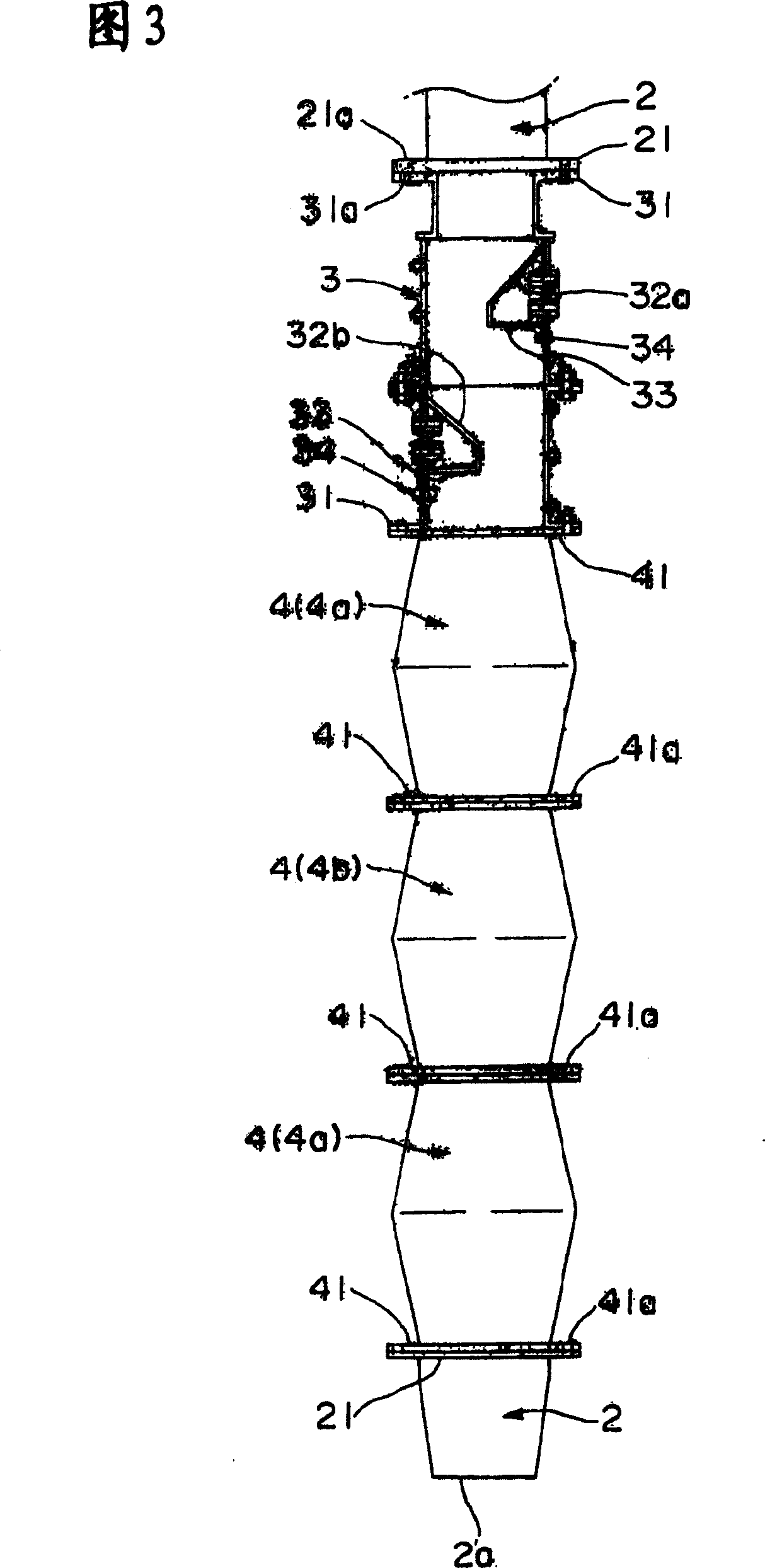

[0027] Hereinafter, embodiments of the concrete pouring device of the present invention will be described with reference to the drawings. 1 and 2 are schematic diagrams showing concrete pouring work according to an embodiment of the present invention. FIG. 1 is a side view, and FIG. 2 is a plan view. This embodiment is the concrete pouring operation in the bridge pier construction of the viaduct.

[0028] The concrete pouring device of the present embodiment is composed of a crawler crane 1 arranged on an erection work site arranged on a slope, a conveying pipe 2 suspended by the crawler crane 1 , a buffer device 3 connected below the conveying pipe 2 , and the The lower part of the buffer device 3 is connected to the stirring box 4. Moreover, the concrete mixer truck 5 and the concrete pump truck 6 are arrange|positioned adjacent to the crawler crane 1 mentioned above.

[0029] Here, the so-called crawler crane 1 is a type of mobile crane that can move on land, and the cra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com