Coaxial split type motor wheel hub

A split type and hub technology, applied in the direction of motors, hubs, electromechanical devices, etc., can solve the problems of easy damage, collision damage, large torque, etc., achieve simple and compact structure, ensure driving safety, improve reliability and durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

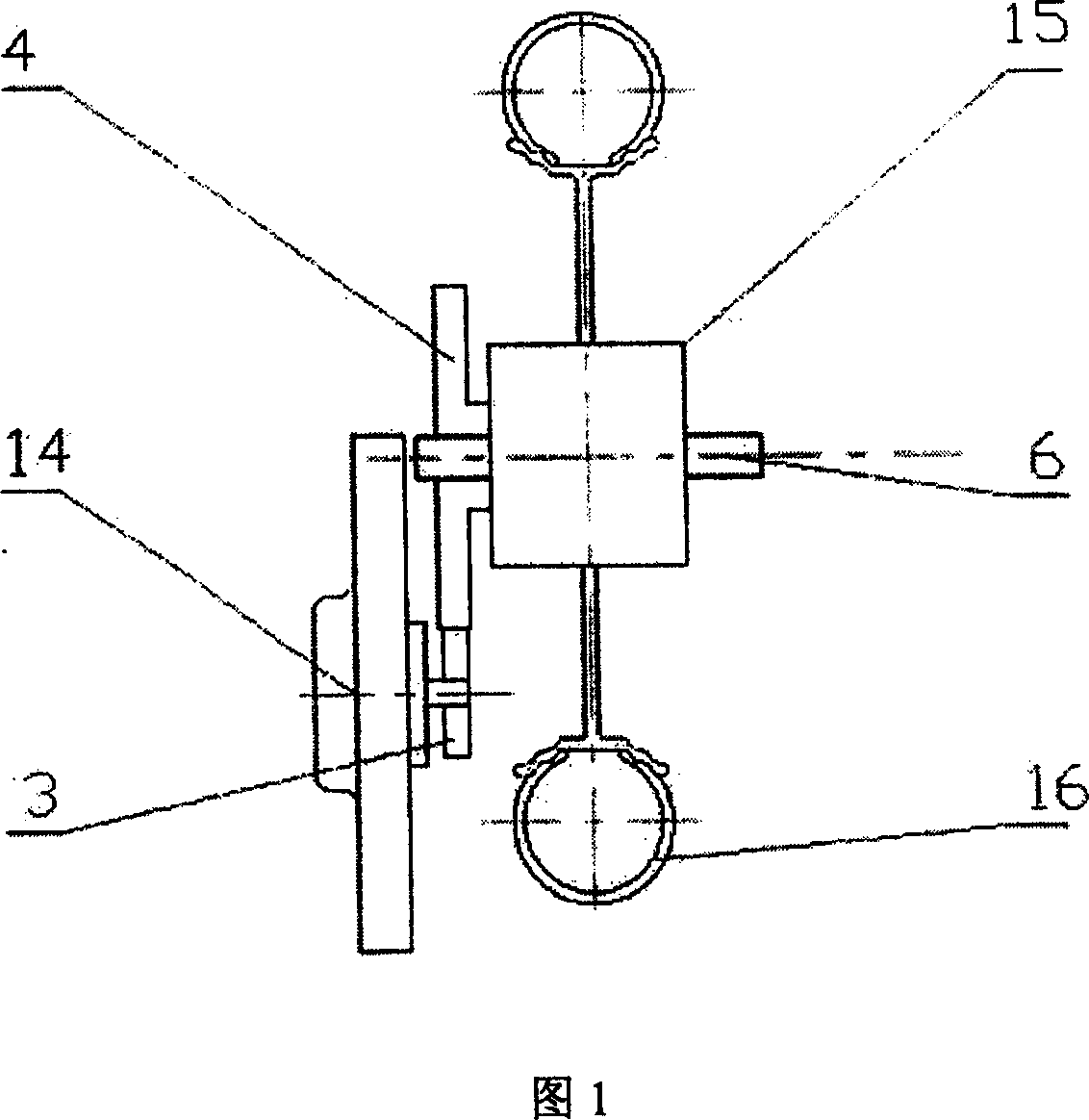

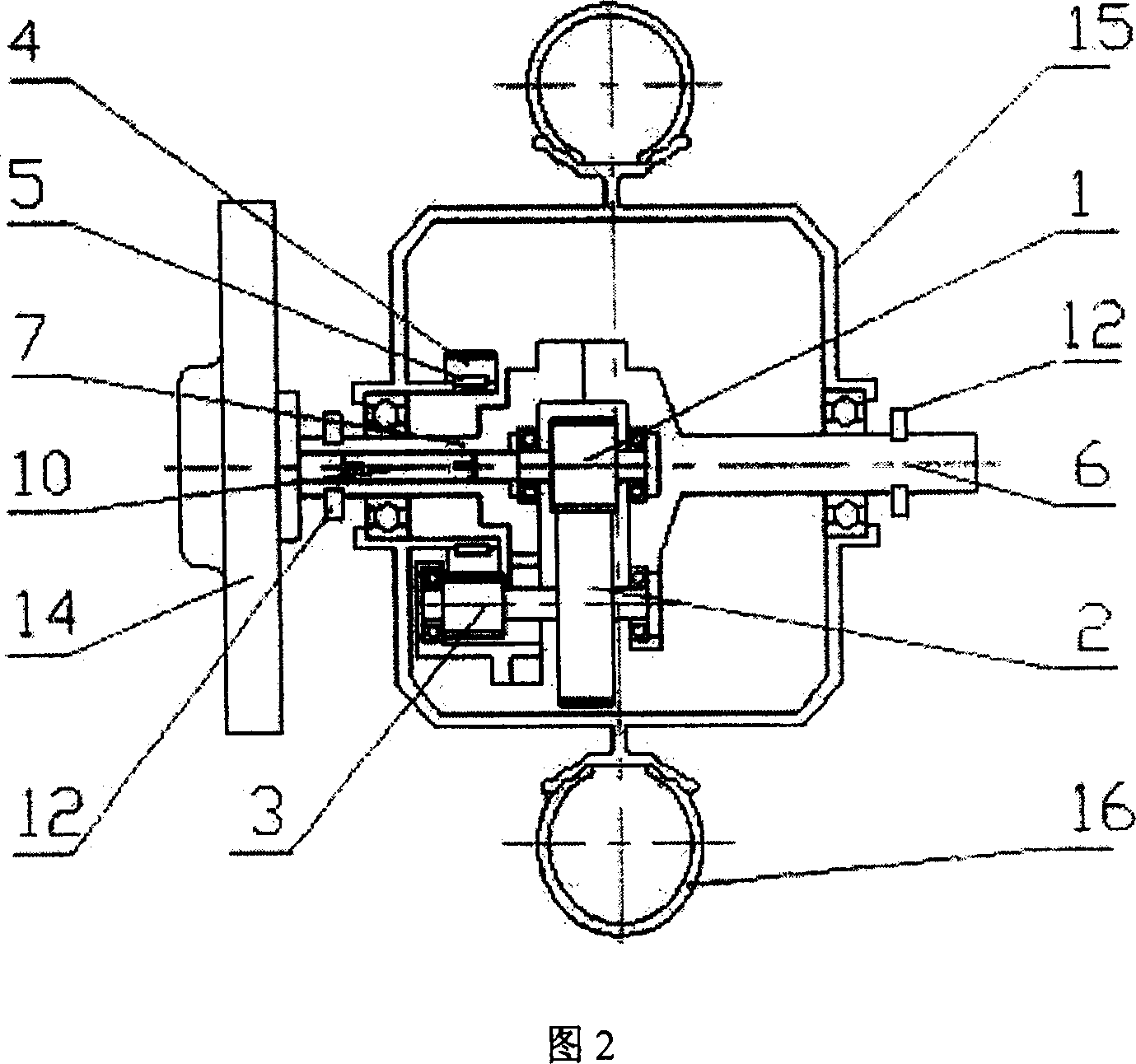

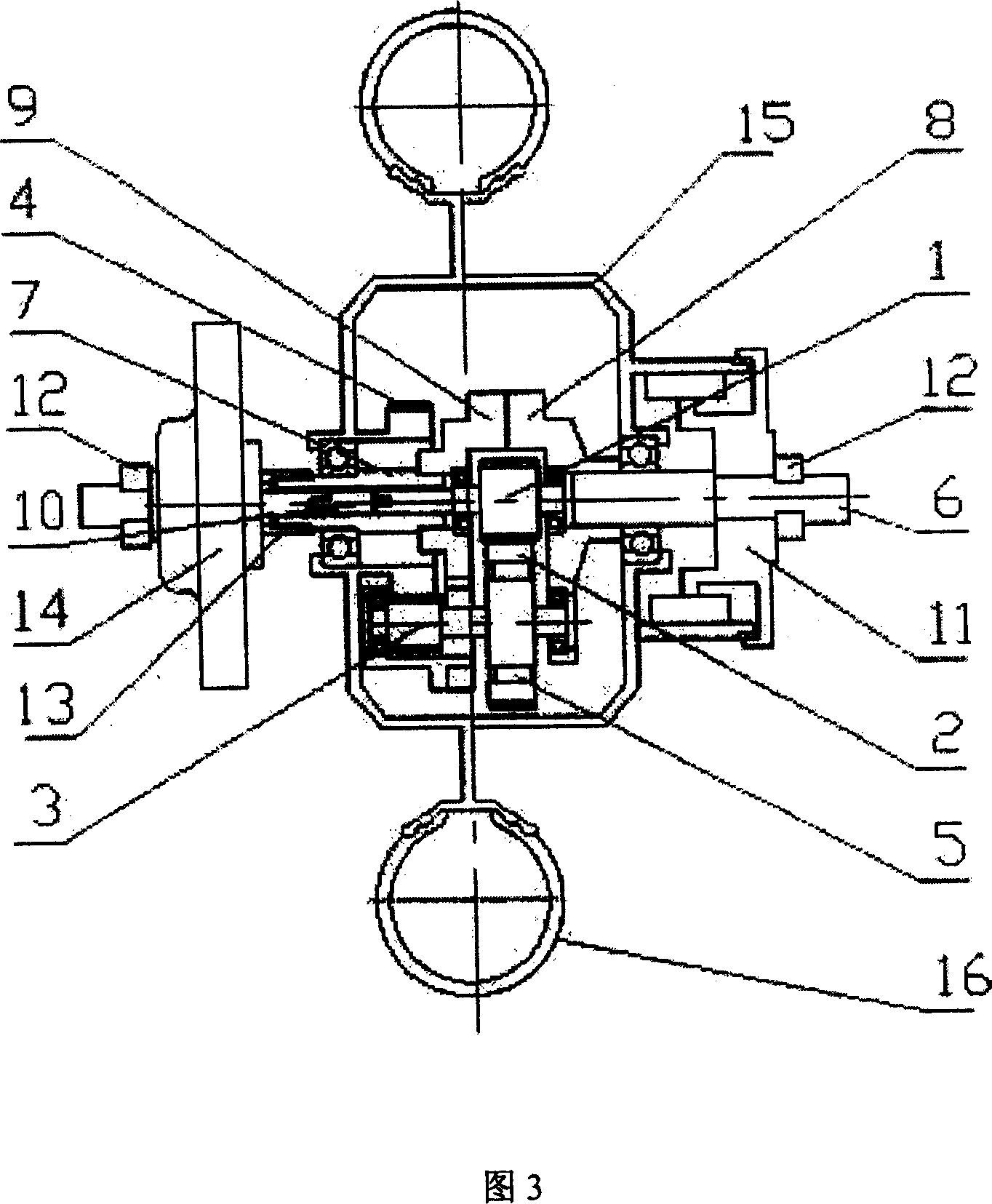

[0024] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0025] The present invention proposes a coaxial-split motor hub, which includes a motor 14, a hub shell 15 and a gear transmission system. Wherein the motor 14 can adopt a rare earth permanent disk type high-speed motor, which is characterized by high rotating speed, high efficiency and hard characteristics. The motor 14 reduces the speed and increases the torque through the gear system, so as to realize high torque output. The gear transmission system is used to transmit power to the hub.

[0026] The motor 14 and the hub shell 15 in the motor hub are coaxially arranged separately, and the central axis of the hub shell 15 is fixed and does not rotate. It is composed of a first half shaft 7 and a second half shaft 6. The two The inner ends of each half shaft respectively fix a disc support frame (the first disc support frame 9 and the second disc suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com