Golf club head and manufacturing method thereof

A technology for golf balls and manufacturing methods, applied to golf balls, golf clubs, rackets, etc., can solve the problems of reduced overall volume, increased spacing, waste of welding materials 34, etc., to achieve improved accuracy and efficiency, and better integration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Before the present invention is described in detail, it should be noted that in the following description, similar elements are denoted by the same reference numerals.

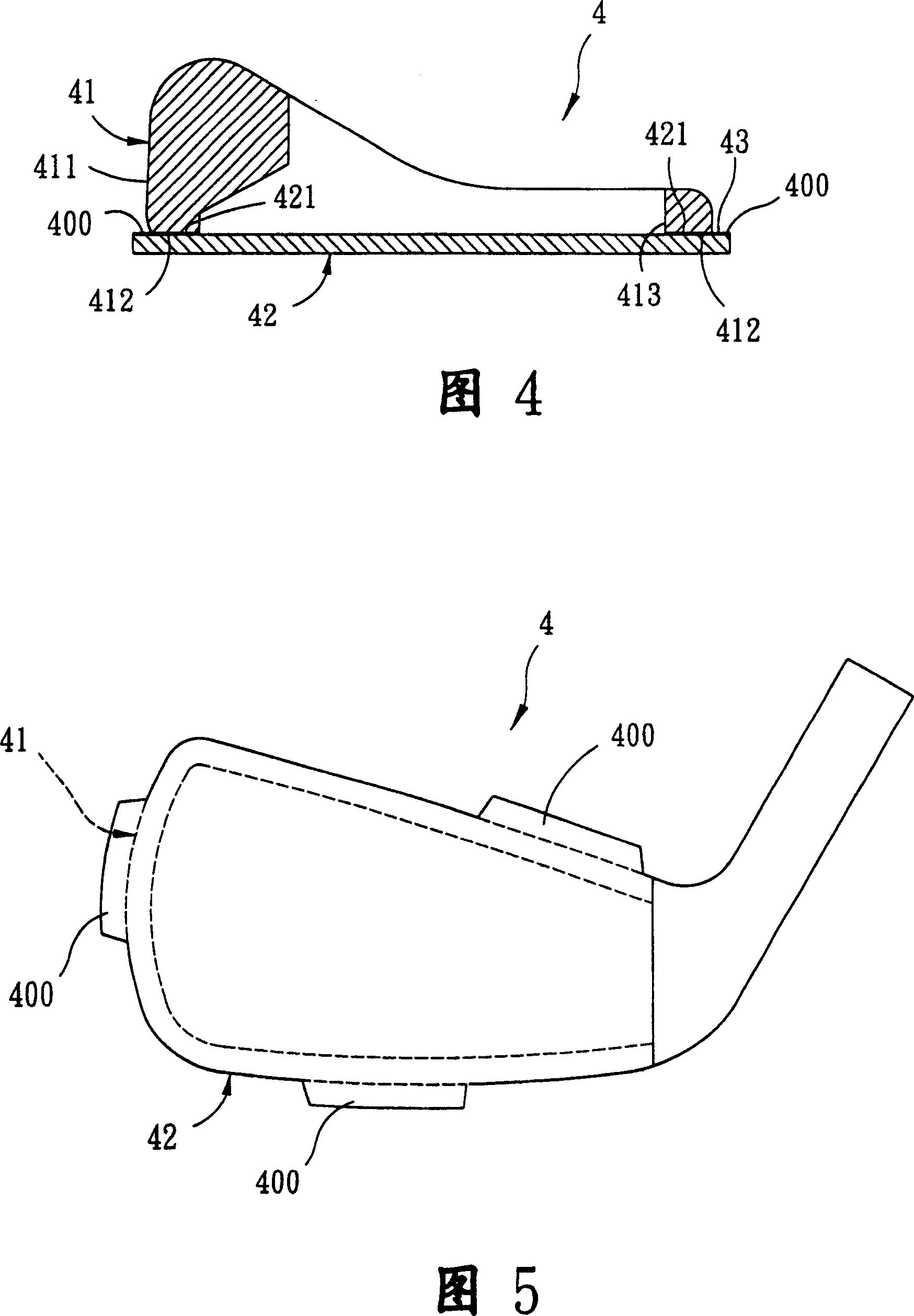

[0049] Referring to FIGS. 4 and 5 , the first preferred embodiment of the golf club head 4 of the present invention is an iron club head, and includes: a shell 41 , a striking panel 42 , and several brazing materials 43 . The shell 41 , the striking panel 42 and the brazing material 43 are made of different metal materials, wherein the melting point of the brazing material 43 is lower than the melting point of the shell 41 and the striking panel 42 .

[0050] The shell 41 has a body 411, and a protruding joining portion 412 formed around the periphery of the body 411 (because the joining portion 412 is in a surrounding shape, it is shown as two joining portions 412 in the side view sectional view of FIG. display state), and an engaging block 413 protrudes from the engaging portion 412 . The striking pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com